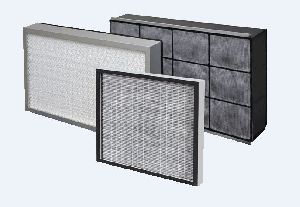

SAF ACF Series Activated Carbon Pocket Filter

Get Price Quote

50 Piece (MOQ)

SAF ACF Series Activated Carbon [G3-F9] Our SAF ACF Series Activated Carbon Filter Pockets are composited by high- adsorption activated carbon fiber and filter media, with fine surface adsorption ability. It can get rid of both particulate & molecular like dust, odor, sulphur dioxide and other volatile organic pollutants in the air effectivel

Compact Band Filter

Get Price Quote

Universal compact band filter is designed after decades of experience and understanding the needs for latest technology in filtration. As the name suggests the system requires 70% less space than conventional band filters with higher degree of filtration utilizing minimum filter media.The specially designed conveyor belt of semi circular shape allows greater filter area and efficiency in working. The media is sealed from all sides and there is no chance of contamination escape. The higher head of coolant that gets stored in the filter offer better filtration through the media as compared to switch mechanism. Needs almost no manual attention. Ideally suited for machine tools and process industries. It can also be supplied with magnetic coolant filters and chilling units for higher level of filtration. Capacity can be supplied upto 2000 lpm and above.

Best Deals from Electronic Filter

SinE-Series Active Harmonic Filter

165,000 - 225,000 Per Set

1 Unit (MOQ)

HEPA Activated Carbon Pre Filter

Get Price Quote

Air Purifiers for room Air Filtration and its Practical Application The essential functions of HEPA+CARBON+PRE Filters are to improve indoor Air Quality and to protect downstream equipments and facility components. Good HEPA+CARBON+PRE Filters controls all human sneeze droplets. Proper filtration selection is critical to ensure operator safety from potentially harmful odors, vapors and airborne particulate. When selecting a filter for your application, ‘MICRON filters reviews the complete application to make certain the proper filtration package is selected. At our state-of-the-art facility in Sonipat HARYANA.MICRON filters are manufactured to the strictest quality standards in the industry. Our filters have undergone thorough laboratory testing to ensure their capability to meet your application challenges. Particulate Pre-filters The particulate pre-filter is an electrostatically charged fiber filter which effectively removes submicron particulates. It is designed to protect the adsorption filter from contaminants such as smoke, acid mists, and other submicron particulates. All units are initially supplied with a pre-filter. Multiple Application Filters These filters are designed to remove a wide variety of contaminants. They are multi-layered filters according to general use or customized for special applications. For removing both chemical vapors and fine particulates, there is a special two-stage filter consisting of activated carbon (A/C) and HEPA. Activated Carbon Filters Mystaire activated carbon air filters consist of high-grade coconut shell carbon. The steam activated nutshell provides a large surface area and an extensive internal pore structure for a high degree of adsorbency. HEPA Filters High Efficiency Particulate Air (HEPA) Filters are available in various configurations for the containment of particles. The filter has a 99.997% efficiency rating for collecting 0.3 micron particles. Chemisorptive Carbon Filters To remove lighter weight gases that are not physically adsorbed by activated carbon alone, an impregnant is added to these filters. The impregnant utilizes chemical and physical attraction to enhance adsorption. ULPA Filters Ultra Low Particulate Air (ULPA) Filters are available in various configurations for the containment of particles. This filter has a 99.999% efficiency rating for collecting 0.125 micron particles. Dual Purpose Safety Filters The safety filter has been designed to incorporate both gas phase and mechanical phase filtration into one safety filter. The dual purpose safety filter is critical to ensuring operator and laboratory safety as it provides adequate reserve gas phase capacity as the primary filter(s) reach saturation. Thickness / Density : Thicker or denser filter media have higher filtration efficiency and higher pressure drop. Deeper, graduated filter medias can hold more contaminants, than thin media grades. Fibre Quality / Size : Quality air media lasts longer and does not shred fibres in the duct. Fibre size can have various effects on efficiency. Surface Area : Higher media surface area equates to a lower pressure drop and higher contaminant holding capacity. Pleated air filtration media has a greater surface area and contaminant holding capacity than flat air filtration media. The higher the number of pleats, the larger the surface area it can contain. Ultimately, the higher surface area maximises the filtration and contaminant holding capability and reduces energy consumption HEPA+CARBON+PREFilters standards Globally accepted HEPA+CARBON+PRE Filter performance rating systems are EN779:2012 (G1 to F9), EN1822:2009 (E10 to U17), ASHRAE 52.2 (MERV 1 to 16) ISO16890 (ISO coarse to ISO ePM1).

Activated Carbon Filter

15,000 - 26,850,000 Per Piece

1 Piece (MOQ)

Activated Carbon Filter

20,000 Per Piece

1 Piece (MOQ)

Activated Carbon Filter

15,000 - 15,500 Per piece

1 Piece (MOQ)

An activated carbon filter is a device that can remove certain types of chemicals from water, thus making it safe for consumption. It can eliminate organic chemicals and also those that give bad odor or taste to water, like chlorine or hydrogen sulfide. It is used in a water filtration system for this purpose, and it works to make the water tasty to drink. In today’s times, with growing pollution affecting the environment, activated carbon filtration is increasingly becoming a solution to cleaning up water because of its ability to absorb contaminants.You can find the Aqua Systems Technology activated carbon filter being placed inside a water treatment plant. Some of the many substances that it can remove are heavy metals, chloride, pesticides, chloroform, VOCs (present in gasoline, industrial cleaners, solvents), trihalomethanes, tannins, by-products of water disinfection, and algae toxins. Carbon sourced for the filter can come from bituminous coal, peat, or coconut shells. The process by which a carbon filter removes contaminants is called adsorption, where impurities are attracted by the filter's activated carbon and get stuck to it. The filter alters the chemical composition of these impurities and makes the water pure for consumption.A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standardsAqua Systems Technology is one of the best Activated Carbon Filter manufacturer, Activated Carbon Filter exporter, Activated Carbon Filter supplier in mumbai India. We are provide this Activated Carbon Filter product in all over countries. If you have this Activated Carbon Filter product please visit here or quote Now.We are one of the leading manufacturers of Activated Carbon Filter. They are manufactured in compliance with industrial quality standards and are used for effective removal of color, odor, organic contamination and chlorine from water. They are made using mild steel and are operated under pressure. Their back flushing arrangement effectively flushes away the deposited impurity at carbon granules. We offer this product to clients at affordable costs.Features : Durable Easy to install Excellent quality It is used for effective removal of color, odor, organic contamination and chlorine in water. The activated carbon also removes certain chemicals that are dissolved in water passing through a filter containing GAC by trapping the chemical in the GAC. However, other chemicals, like sodium or nitrate, are not attracted to the carbon and are not removed.Activated carbon filters are made from mild steel/FRP closed vessel incorporating frontal piping fitted with valves and are operated under pressure. The water is passed through the under bed media & granular activated carbon layer. Where the carbon granule at certain level absorbs unwanted impurities for removal of free chlorine, phenol, taste and odor as well as reduction COD/BOD etc. Carbon filter have back flushing arrangement, which very easily flushes away the deposited impurity at carbon granules. Thus the reverse flow of water flushes away the impurities deposited at carbon granules. Activated Carbon Filter, for removal of free chlorine, phenol, taste and odor as well as reduction in COD/BOD.

Activated Carbon Filter

5,000 - 200,000 Per No

10 Piece (MOQ)

Automatic Compact Band Filter

Get Price Quote

1 Unit (MOQ)

COMPACT BAND FILTERS Compact Band Filter is designed to filter ferrous and non-ferrous solid particles from liquid with high degree of purification using paper as filter media to enhance life of liquid and protect surface finish of products. Compact Band Filter works both with water base emulsion coolant as and oil(neat oil).MOC of Compact Band Filter is mild steel, SS-304 and SS-316. The fluid with dirt is passed to compact band filter through inlet pipe. Float actuated drives motion and indexes dirty filter paper. A compact band filtration system is a type of filtration system designed to efficiently remove impurities, particles, or contaminants from a fluid, typically a liquid, within a specific band or range of particle sizes. These systems are commonly used in industrial and commercial applications to ensure the quality and cleanliness of fluids in a space-saving and cost-effective manner. General Description: Transfer pump is fitted on Dirty coolant tank to supply the coolant to the filtration system. Operation logic of Transfer Pump is based on the Level Indicators on Dirty and Clean tanks. Once the filtration system is switched ON, Transfer pump is started based on high level in Dirty tank. Transfer Pump is cut off if coolant level goes low level in dirty tank or coolant level goes high level of clean tank. Compact Band Filter is placed on top of Clean coolant tank. Compact band filter uses paper filter to remove impurities from the coolant and filtered coolant gets collected in Clean tank. Supply Pump is mounted on the Clean tank of filtration system. Coolant from Clean tank is transferred to machine using this pump. This Supply Pump is started based on the signal from the machine. Supply Pump is switched off if coolant level goes low in clean tank. Key features and components of a compact band filtration system may include: Filter Media: The heart of any filtration system is the filter media, which can be made from various materials such as paper, fabric, metal, or synthetic materials. The choice of filter media depends on the type and size of contaminants to be removed. Filter Element: Compact band filtration systems typically use filter elements that are designed to trap particles within a specific size range. These filter elements can come in different shapes and configurations, including cartridges, bags, or screens. Inlet and Outlet Connections: These systems have inlet and outlet connections to allow the fluid to enter and exit the filtration system. These connections are typically designed for easy integration into existing pipelines or fluid systems. Control System: Advanced filtration systems may incorporate a control system to automate filtration processes, monitor filter performance, and trigger cleaning cycles as needed. Size and Portability: Compact band filtration systems are designed to take up minimal space while still providing effective filtration. This is especially important in situations where space is limited or where mobility is required. Application-Specific Design: These filtration systems can be customized to meet the specific requirements of different industries and applications, including oil and gas, automotive, food and beverage, pharmaceuticals, and more. Maintenance and Serviceability: Easy access for maintenance and replacement of filter elements is a crucial consideration in the design of compact band filtration systems to minimize downtime and maintenance costs. Features : Suitable for fine filtration. Filtration capacity. Very low maintenance. Totally automatic operation. Very compact design for individual machine. Can be customized to suit your requirement. Filtration capacity: 10 lpm to 3000 lpm Advantages : Increase tool life Increase surface finish of components. Extending coolant life Reduces hazards waste Cleaner working environment Reduces machine down time Increased machine output. Application:- Bearing industry. Auto component manufacturers. Automobile manufacturers. Cold Rolling mill. Waste water treatment plants. Food processing.

Activated Carbon Filter

Get Price Quote

1 Piece (MOQ)

DEFINE Activated Carbon Filter is used to adsorb chlorine, organics , taste, odour, and colour from Water & Wastewater. OPERATING PRINCIPLE Activated carbon filtration is an adsorptive process in which the contaminant is attracted to and adsorbed onto the surface of the carbon particles. The efficiency of the adsorption process is influenced by carbon characteristics (particle and pore size, surface area, density and hardness) and the contaminant characteristics.

Activated Carbon Filter

Get Price Quote

Activated Carbon Filter

60,000 Per pieces

1 pieces (MOQ)

Bonnafide Chemicals is the principal dealer of Activated Carbon Filter. We are reckoned in the markets for the supplying of Activated Carbon Filters, which are available in varied sizes, material range, and compositions . Salient Features Designed to remove free chlorine, organic matter, odor and color present in the feed water with minimum pressure drop. The activated carbon filters contains activated carbon granules of defined iodine absorption values as per the application. Water enters the filter and percolates through the filter bed. Free chlorine, organic matter, odor, and color are absorbed by the Activated carbon. Treated water then goes via the filtration nozzles through the filter outlet. Advantage Easy to operate Requires least maintenance Excellent filter quality at higher flow rate than conventional ones Low pressure drop Application Pretreatment of all forms of industrial water treatment Pretreatment to all forms of potable water treatment and metal recovery

Activated Carbon Filter

Get Price Quote

1 Piece (MOQ)

Activated Carbon Pleated Filter

850 Per Piece

5 Piece (MOQ)

Active Harmonic Filter

Get Price Quote

Features Fast 32 bit digital signal processor Synchronous Rotating Frame Principal for best performance Ultra fast compensation Proven performance on welding Harmonic Attenuation of more than 96% Selective Harmonic compensation Leading/Lagging Reactive Power Compensation Negative Sequence Compensation (load balancing) Zero Sequence Compensation (neutral compensation) 15 possible Priority Selection settings for maximum flexibility Smart auto fold-back to avoid over loading of filter 7" touch screen display Ethernet based remote monitoring MODBUS RTU, USB, SD Card Internal CAN Communication Closed Loop & Open Loop operation Paralleling of upto 32 filters for higher capacity Operator Activity Log >1,00,000 time stamped events can be logged in internal NAND memory Benefits Compliance with prescribed harmonic limits - No penalty Unity Power Factor - higher savings Reduced energy (kVAh) charges - higher savings Reduced peak demand charges - higher savings Reduced fuel consumption in generators - higher savings Ultra fast compensation - effective with fast fluctuating load Proven performance on welding Optimum capacity utilization of electrical infrastructure Optimum capacity utilization of backup generators Improved voltage profile Reduced risk of transformer failure - higher uptime Reduced risk of equipment failure - higher uptime Increased operational reliability - higher uptime Compact footprint Indigenous design, low maintenance and prompt service

Activated Carbon Filter

Get Price Quote

The Activated Carbon Filters are manufactured in MS / SS / FRP / MS/RL etc. They contain a perforated plate at bottom with layers of Activated Carbon. When the fluid passes through the Activated carbon bed, the odor / smell is retained by the carbon and odorless fluid passes through. When the carbon bed gets saturated, it is replaced with new one.The Activated Carbon Filter finds applications in : Pharmaceutical industry Dairy & food products Beverages Package drinking water Cosmetics Thermal power plants Agriculture

Activated Carbon Filter

25,000 - 500,000 Per Piece

1 Piece (MOQ)

We make available fine quality Activated Carbon Filters which are reckoned for their make and long service life. Activated carbon (AC) is generally used in water treatmentfor removing free chlorine and / or organic compounds. Removal of organics from potable water could be to prevent common organic acids such as humic or fulvic from reacting with chlorine to form trihalomethanes (a class of known carcinogens).

Emi Filter

1,500 - 3,500 Per piece

100 Piece (MOQ)

RFI (Radio Frequency Interference) Filter,EMI Suppression Filter,Power Line Noise Filter,Signal Integrity Filter,Electromagnetic Shielding Filter

Granular Activated Carbon Cartridge Filter

300 Per Piece

10 Piece (MOQ)

Compact Paper Band Filter

50,000 - 500,000 Per Piece

1 Piece (MOQ)

Fully automated our compact band filters are easy to operate and provides cost effective solution for filtration. These compact band filters are specially designed for space efficiency and require only 20% of the space as compared to other compact band filters. The hydrostatic head and the perfect sealing of the machine ensure that there is no leakage or overflow of the material and high filtration efficiency is achieved. Engineered to precision, these compact band filters well suited for high flow rate and dirt content. Paper cartridge, washable cartridge, and stack type filter elements are available. System used to achieve final filtration level. Range: 30 LPM to 1000 LPM in one module. Suitable to max, working pressure 30 bar & pressure drop Of 3 bar across filter. Clarity level : 75 microns to 3 microns.

Anti Surge Cum Filter

7,847 Per Piece

1 Piece (MOQ)

Anti Surge Bottles are used in the spray painting line in order to reduce the surge or fluctuation of the spray machine while the spray or painting application for the smooth and un-interrupted functioning of machine.

Dual Media & Activated Carbon Filter

Get Price Quote

We are one of the dependable names for matchless Dual Media & Activated Carbon Filter. We specialize in manufacturing Dual Media & Activated Carbon Filter that is ideal for the removal of suspended solids and BOD, COD & Colors for ETP & STP. We use only premium grade MS/ SS/ FRP materials to manufacture these filters. These Prefabricated Vessels are used for water and wastewater treatment. Details Sizes Available : 1 m3/ hr to 100 m3/ hr Price : Variable as per Size Applications : Process Industries & STP Colors & Packaging : As per customer's requirement Used For : For removal of SS, COD & BOD for water/ wastewater

HVAC Activated Carbon Filter

4,000 Per Piece

12 Piece(s) (MOQ)

Compact Band Filter

Get Price Quote

1 Piece (MOQ)

Ranked amidst the leading Manufacturers, Exporters & Suppliers of Compact Band Filter; we are a renowned name in this domain. Durable, cost effective, perfectly designed, manufactured and highly reliable; the Band Filter is sternly manufactured in the advanced manufacturing unit. We are backed with a pool of veteran employees and professionals, they keep a check on the Band Filter and ensure that the same is as per the set global standards. Principle : The principle of filtration though ADVANCE “Gravity + Hydrostatic Head” which together offers the required pressure for the fluid to pass through the filter media. The solid contamination settles by Gravity on the Filter Media forming the dirt cake. This dirt cake in turn acts as a fine filter.Construction : ADVANCE CBF comprises of 2 disc wheels connected by a hallow shaft in the centre and Doctor Blades (Scrapper Blades) at the Periphery. The 2 discs are perfectly parallel to each other and mounted vertically in the System. The float switch is provided to sense and maintain the Fluid level in the Trough. The float switch helps in sensing the rising level of the fluid and the indexing. A continuous Honey Comb Belt is positioned tangentially to the Disc Wheel at the bottom with the help of 4 shafts. The front Shaft is the Driveshaft. The Rear Shaft helps to maintain the tension on ‘Honey Comb Belt’ to be perfectly tangential to the discs. The Filter Media is placed between the Discs and the ‘Honey Comb Belt’. The Discs along with the Honey Comb Belt and the Filter Media together form the ‘Trough’ where filtration takes place. Operation : The contaminated fluid is allowed to enter the ADVANCE CBF from either of the sides or both the sides from the flanged inlets. As far as possible the contaminated fluid for filtration is allowed to get in to the ADVANCE CBF with steady low velocity to avoid the turbulence when it drops on the ‘Trough’. The Fluid drops in to the trough through a dispenser on the rear side of the system i.e. the virgin filter media side. A small water fall effect is created while dropping the fluid through the dispenser. The solid particles settle by Gravity on the Filter Media forming a cake, which in turn acts as a fine filter. The Filter Media by itself attains the Roll of the support media. The fluid passes through the dirt cake and the filter media with the help of the Gravitational Force and Hydrostatic Head. The rising fluid level in the trough is sensed by the float switch and the system indexes. When the indexing takes place, the virgin media is introduced from the rear side of the system. The exhausted media with the dirt cake is discharged from the front of the system. The doctor Blades connecting the wheels at the circumference acts as the scrapper blades, which slowly and surely discharges the solid dirt cake.

Activated Carbon Filter

Get Price Quote

1 Piece (MOQ)

EtchON EMI Filter

Get Price Quote

Activated Carbon Filter

Get Price Quote

1 Piece (MOQ)

Activated Carbon Filters (ACF) are used to remove odour, colour, free chlorine etc & improve the taste of the water. It is usually employed after the media filter & used for water & waste water treatment applications. Activated carbon of suitable lodine Value as per application is selected as the filter media.

Co2 Laser EMI Filter

800 Per Piece

1 Piece (MOQ)

Compact Band Filters

250,000 - 3,000,000 Per piece

1 Piece (MOQ)

Our Compact Band Filters are an optimal solution in coolant filtration in industrial processes that require precision and a continually high level of performance. Compact Band Filters offered by us as a reliable Compact Band Filters Exporter facilitates better filtration to achieve near zero contamination for optimal benefits to the associated machinery. These filters are small, and slim and the new models have the most enhanced filtration mechanism that ensures complete separation of all the impurities thus increasing the useful life of both the coolant and the related equipment. Designed to be as long-wearing as possible, our Compact Band Filters run with low maintenance requirements and thus lower the frequency of possible stops. Designed specifically for machining, grinding, and similar industrial uses, they maintain the stability of liquid and accurate quantity. Our filters come in different sizes and the options can be adjusted to serve a variety of industrial conditions. As a credible Compact Band Filters Exporter, you can rely on our knowledge to provide expert professional advice with a wide range of high-quality and efficient filters ideal for maintaining your smooth and cost-effective workflow.

Activated Carbon Filter

125,000 Per Piece

1 Piece (MOQ)