electro plating rectifiers

100,000 - 500,000 Per Set

1 S (MOQ)

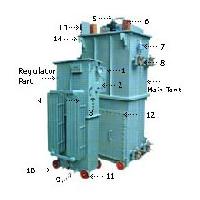

The output DC voltage variation is step less by means of ON LOAD motorised regulator. We use vertical ROLLING CONTACT TYPE voltage regulator, wound with heavy section of copper strip, suitable for 100% continuous duty cycle. The life of these regulators is more than 25 years and have 4 - 5 % better efficiency in comparison to conventional dimmerstat type regulators. - Please note that Rectifiers manufactured by us, we are using plusminus type (+ 254 Volts OR + 440 Volts) Voltage regulator in "Q" connection - which means that the capacity of voltage regulator required in our Rectifier winding design is 50% in Star connected (+ 254 Volts) model and 30% in Delta connected (+440 Volts) than straight type (0-440 Volts) voltage regulator used by conventional design rectifier winding. - With PlusMinus type voltage regulator used in our rectifier design, the capacity of Voltage Regulator used remains the same, but the brush current of the Regulator reduces and the reliability of regulator increases. This results in considerable saving in overall power losses of our Rectifier equipment.

Electroplating Rectifier

105,000 - 1,050,000 Per piece

1 set (MOQ)

A.B. Electricals is a trusted Electroplating Rectifier Supplier. Our rectifiers have a stellar reputation for efficiency. For every product, we guarantee the same level of quality. Our rectifiers operate consistently and dependably. Before shipment, every rectifier is put through a thorough testing process. At A.B. Electricals, client happiness comes first. We provide a variety of rectifiers to meet your demands. Our goods can be used in a variety of electroplating applications.Our Electroplating Rectifier is made with installation ease in mind. They guarantee long-term usage with little upkeep. We offer every customer technical help. Our group has a wealth of experience and expertise. We guarantee prompt delivery of every purchase. A.B. Electricals makes use of cutting-edge technologies. Our rectifiers use less energy, which lowers operating expenses. Both small and large enterprises are served by us.Our goods meet industrial requirements. We aim for perfection in all that we do. Customers rely on us because we are dependable. Pricing at A.B. Electricals is competitive. Our rectifiers improve the electroplating operations' efficiency. In the industry, we are highly regarded.Our clientele is expanding and diversified. For high-quality electroplating rectifiers, go with A.B. Electricals. Get outstanding performance with our products. If you require an electroplating rectifier, get in touch with us. We are available to help you. Our first goal is to make sure you're satisfied.

Best Deals from Electroplating Rectifiers

IGBT Based Electroplating Rectifier

75,000 Per

1 Piece (MOQ)

Dc Rectifier Unit

50,000 - 5,000,000 Per Nos

1 Piece(s) (MOQ)

These Rectifier units are suitable for all electro deposition processes within their rating. The widest applications in the field require maximum voltage of 8V, 12V and 20V D.C. at various current capacities as per requirement. A range of current ratings from 100 amps to 10000 amps is covered in our regular manufacture. Our standard sizes are listed in the price list issued separately. Brief Specification Input Voltage: 360 to 440V A.C. 3 Phase 50 Hz 4 Wire Output Voltage: Continuously variable from zero to the full rated D.C. voltage Output Current: From zero to Rated maximum D.C. Current Efficiency: Above 80% Temperature Rise: Less than 45°C above ambient at the top of the oil

Electroplating Rectifiers

100,000 - 200,000 Per Piece

1 Piece (MOQ)

Electroplating Rectifier

70,000 - 250,000 Per piece

1 No (MOQ)

Our firm specializes in offering a high quality range of Electroplating Rectifier. In sync with different need of our clients, our provided product is processed making use of advance technology under the assistance of our highly trained employees. The product provided by us is broadly used in different applications in electronic domain.

Electroplating Anodizing Rectifier

Get Price Quote

1 Piece (MOQ)

A variable voltage D. C. source is required for the Electro deposition process of electroplating, anodizing etc. The various ratings of voltages and currents required for the process depends upon the metal to be deposited and the process adopted. MARSZ Rectifiers are designed in standard voltages of 8 V to 24 V, and in current ratings varying from 100 Amps up to 10000 Amps. Up to 24V DC 10000 Amps for Electroplating and Anodising. Brief Specification: A.C. INPUT Rectifiers are designed to work on 415 V AC 3 ph. 50 Hz. supply and suitable for an input range of 360 V to 460 V AC 3Ph. Units of very small capacities namely 8 V / 12 V / 16 V / 20 V & 24 V DC up to 100 Amps ratings can also be supplied to work on an input voltage of 240 V AC 1 ph. 50Hz. supply. D.C. Output The DC output is continuously adjustable from zero to full rated value, from no load to full rated current, over the input range as described. All 3 phase units have low ripple of less than 5% and are suitable for all special processes such as chrome plating or hard chrome plating where low ripple content is necessary. Circuit and Components The units are assembled with high quality materials, and the components are manufactured to relevant specifications. MAIN TRANSFORMERS: The transformers are of class ‘A’ insulation and conform to IS 2026 in general. The laminations used are C.R.G.O Silicon steel, low loss type. The wound coils are impregnated with oven baked varnish. I.P.T: For high current units the transformers secondary is generally double wye. An I. P. T. wound with copper, is provided on its secondary, to extend the conduction period of windings and diodes. Silicon Rectifier: The Rectifier is assembled by using silicon diodes, mounted on heat sinks and connected in full wave circuits. Individual R.C. components are used for hole storage protection. The diode assembly is always selected to have at least 40% extra rating above the maximum output current. Regulator: In order to facilitate voltage variation from zero onwards “VARIVOLT” variable voltage auto transformers are used as independent units, or some times, accommodated in the transformer tank. Motorization is provided as an optional feature. The DC output is continuously adjustable from zero to full rated value, from no load to full rated current, over the input range as described. All 3 phase units have low ripple of less than 5% and are suitable for all special processes such as chrome plating or hard chrome plating where low ripple content is necessary Protection & Metering MCB / MCCB protection is provided on the input and 3 fuses are provided on the output of the “VARIVOLT” variable auto transformer. 3 pilot indicators are incorporated on the incoming side. Digital voltmeter and ammeter with suitable shunts are provided to read the output voltage and currents. Optional Features Following optional features can be provided: Remote switching-on by using contactors and bimetal over load relays. Push button operation by motorization of the “VARIVOLT” variable auto transformer. Constant voltage or constant current features using electronic circuits. “VARIVOLT” auto transformer with zero start facility. Timers, time totalizers, ampere hour meters, etc. Dimmerstat Output is an important factor in Electrode position processes. MARSZ provide a step less and continuous variation of output voltage, which is a far superior method to other methods of control like resistance boards, tap switches etc. The step less variation is achieved with the help of Dimmerstat’ which is Registered Trade name for Continuously Variable Voltage Auto Transformer manufactured by MARSZ. Unlike other methods of output control, Dimmerstat provides a step less, on-load and without break variation of output Voltage, without any loss of power. It being one of our own standard products, availability of spares or replacement is guaranteed, although the necessity is very rare. H.R.C Fuses Overloading or short circuiting is not a rare occasion in Electro deposition processes. Special High Rupturing Capacity (H.R.C.) fuses are therefore provided on the primary of the Main transformer. These fuses will blow only when there is overload or short circuit on the output or if there is an internal short circuit and in such cases they should be replaced by H.R.C. fuses of the same rating only. Double Wound Transformer This is of conventional design and conforms to standard specifications of IS 2026 as regards the temperature rise and insulation are concerned. The primary is delta connected and two secondaries have star connected windings. Interphase Transformer The IPT is connected between two star points of the secondaries of the main transformer; The Interphase transformer improves commutation thereby increasing the rating of the Rectifier. Rectifier These is made up of sturdy liberally rated Silicon diodes and are arranged in a six phase circuit. The diodes are mounted on cooling fins so as to dissipate the heat thereby increasing the rating of the diode. Depending upon the output current rating, necessary number of diodes is connected in parallel. Metering A Voltmeter and an Ammeter are provided on a separate panel to indicate the output voltage and output current. The panel is mounted on one of the tanks to enable easy manipulation with the help of the Dimmerstat. The ammeter is used in conjunction with an external shunt, which is fitted inside the tank. Construction The units are made in natural oil immersed construction. Any Electro deposition process is always associated with acidic and corrosive fumes and dust. Any contact with these fumes and dust obviously reduces the life and reliability of the Rectifier. Oil immersed construction offers best protection to the Rectifier unit in this regard and therefore increases the life enormously. The Dimmerstat is always housed in separate tank. For rectifier units up to a maximum output capacity of 100KW, the transformer and the rectifier are housed in one single tank. For higher capacities separate tanks for transformer and rectifier are used. For rectifier units of current rating 5000 amperes and above, the rectifier is supplied in Separate tank for better cooling. If the customer can guarantee that sufficient precaution is taken to see that corrosive fumes and dust do not come in contact with the rectifier unit, we will be pleased to make special offers for units in Air cooled or combined OIL/AIR cooled construction. Connection The mains supply is to be connected to the Dimmerstat input terminals by a cable of proper size through a switch fuse unit. The cable of same size should be used for connections from Dimmerstat output to the primary of the transformer.

Electroplating Rectifier

213,000 - 2,212,000 Per Piece

1 Piece(s) (MOQ)

Electroplating Rectifiers

8,000 - 12,000 Per Pcs

1 Piece (MOQ)

Electroplating Rectifier

Get Price Quote

Our company is a major Manufacturer, Exporter & Supplier of Electroplating Rectifier. The Electroplating Rectifier is an instrument that is used to convert the AC power supply into DC power supply. We manufacture Electroplating Rectifier using hi-tech machinery and superior quality components. The Electroplating Rectifier, we supply, is used for various electrochemical processes such as hydrogenation, electroplating, anodizing, etc. The Electroplating Rectifier, we offer, consumes less power and is compact and durable. We supply customized Electroplating Rectifier as per the requirements of the customers. Highlights Designed for 100% continuous duty cycleQuality testedEasy maintenanceLess power consumptionLong life

Electroplating Rectifier

78,500 Per Piece

1 Piece (MOQ)

Electroplating Rectifiers

Get Price Quote

Rectifier is an economical & most efficient method of obtaining D.C from A.C. supply. GNEW's rectifiers are designed and engineered for obtaining D.C. from A.C and cover a wide range of current form 10 Amps to 15000 Amps.

Electroplating Rectifiers

100,000 - 500,000 Per Nos

1 N (MOQ)

Dear Sir, Namaskar, we produce IGBT Based Air Cooled Electroplating Rectifiers with a wide range of capacity Starting from 12V 300 Amps to 12 V 10,000 Amps, also we have 18 V and 24 V Ranges with various Current Ranges as per customer applications. kindly let us know your requirement details so that we can suggest you best suitable model and quote. We also Deals in Electroplating Chemical Filters, kindly let us know your detail requirement so that we can suggest you best suitable model and Quote. attach is our product catalog, for more details please feel free to contact us. looking forward to hear from you.

Electroplating Rectifier

Get Price Quote

We hold an expertise to offer our esteemed clients a unique range of Electroplating Rectifier. The provided rectifier are available in various technical specifications as per the requirements of our valuable clients. In adherence to the set industry standards, these rectifier are manufactured by our skilled professionals using high grade components and latest technology. These rectifier are extensively used for electroplating, anodizing and battery charging.

Electroplating Rectifier

200,000 - 300,000 Per piece

1 Piece (MOQ)

Electroplating Rectifier

150,000 - 500,000 Per Piece

Electroplating Rectifiers

Get Price Quote

We offer Electroplating Rectifiers. POWER is an ISO 9001:2000, DUN BRADSTREET (862376458), IEC, FGI, DIC, EEPC & NSIC registered company. Having five manufacturing plants in all over India. We are engaged in the manufacturing of Industrial Transformers up to 10 MVA (Epoxy Cast Resin Construction, Dry Type, Oil Cooled) low and medium voltage, Industrial Automatic Voltage Stabilizer ranging up to 7000 KVA capacity (U.K. based Brentford type), Variable voltage supply (0 – 33000 Volts), Special Purpose Transformers (step up step down, auto transformers, Ultra Isolation Transformers), Rectifier equipments from 0-1500 Volts and up to 25,000 Amps. for Industrial applications. 0-1000Volt0-25000Amp. D.C. for electroplating, anodizing and other electrolysis process.

Electroplating Rectifiers

Get Price Quote

1 Piece (MOQ)

Electroplating Rectifier

Get Price Quote

For payment of an order, buyers can either choose the standard bank transfer method or opt for a cash on delivery one. We safely conduct monetary transactions to facilitate our clients. The material required for preparing quality-centralized product range is sourced from the trusted places and that too after complete quality confirmation.

Electroplating Rectifier

Get Price Quote

Red Phase brings you the finest products designed and engineered by the people who have been in the same field for the last 30 years. Rectifier is an economical and most efficient method of obtaining DC from AC supply. Red Phase manufactures a wide range of rectifiers covering 0-500 Volts and upto 15000 Amps. capacity suitable for Electroplating, Anodising, Hydrogenation and many other Electrochemical processes. The entire manufacturing process is under one roof ensuring 100% quality control at every stage of production. We believe in quality & customers satisfaction. Starting Circuitry Red Phase’s Rectifiers are designed for 3 phase 50 Hz AC input supply and are available for operations at any voltage between 380 and 440 volts, covering a wide range of voltage fluctuations. It is recommended that the input to the rectifier should be connected through a proper protective device, to provide positive protection to personnel and the system, in the event of maintaining or in case a fault occurs. DC Output Control The function of the variable output controls is to control the voltage or current or its operating range by varying input voltage to the main transformer primary. The DC output voltage variation is achieved steplessly 0-100% by means of an ON LOAD roller type Red Phase’s make voltage regulator. Salient Feature Red Phase’s rectifier equipments are wound with electrolytic Prime grade italics to minimise power losses, in comparison to Aluminium italic conductor used by many other manufactures. Our equipments are designed liberally as per capacity and are ideally suitable for marginal over loading conductions. We use verticle Rolling contact type voltage regulator wound with heavy section of copper strips suitable for 100% continuous duty cycle for industrial applications, in comparison to conventional wire wound Regulators used by other manufacturers. The carbon rollers move on both sides of the winding. DIODE : Silicon diodes are tested in house, similar PIV batch and same forward drop diodes are used in the equipment for equal load sharing and reducing the power losses of diodes. LAMINATION CORE : We use imported CRGO Lamination core which have minimum power losses and results in better efficiency of equipment and saving in energy bill PAINTS : Epoxy paint is used which is resistant to acidic environment of plating process and enhance the life of the equipment by preventing it from corrosion. METER : We use reputed make AE/RISHAB make DC meters only which are very accurate and durable. CONSTANT VOLTAGE CONTROLLER (CVC) (OPTIONAL) : We offer CVC Electronic attachment with rectifier equipments, which will maintain constant Output Voltage or Current as per setting automatically-irrespective of input voltage variation. SERVICING : RED PHASE’S have maintained enviable reputation in market in after sales services. This fact can be varified from any of our customers.