expanding mandrel

26,500 Per Piece

hydraulic expanding mandrels

Get Price Quote

We offer Hydraulic Expanding Mandrels. This is applicable for cylindrical grinding. In order to keep transparency in dealings, we offer our clients an invoice including the details of the products, quantities and price on which both the parties agreed for the payment. Moreover, our payment procedure is safe. We are equipped with the upgraded machines and technology, thus, we are capable of making stern packaging of products. To keep the product safe from external factors, we make use of finest packaging material.

Best Deals from Expanding Mandrels

Head Expander

Get Price Quote

Tarang Head expander is an attachment that increases your loading options of your vibration shaker system that enables it to mount larger or multiple test objects. These come in three standard shapes - circular, rectangular and square. Head expander provides a larger surface mounting area for an occasional test object that is bigger in size than the limiting dimensions specified for your shaker system.

expanding mandrels

Get Price Quote

we make all kinds of mandrel

expanding mandrel

11,500 Per Piece

Concentricity Mandrel

750 Per 0

Concetri

expanding mandrels

50,000 Per Pound

expanding mandrels

Get Price Quote

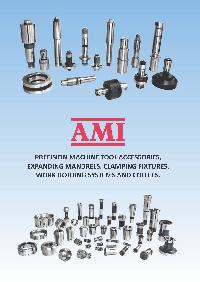

The continuing advancement in production methods in the Metalworking Industry has dcreated a need for precision workholding devices capable of automatic clamping in component bores. In addition, the equipment must transmit the high accuracy of the latest machine tools and develop sufficient holding power to resist the cutting forces imposed on the workpiece.

expanding mandrel

Get Price Quote

The offered mandrel is broadly utilized as a part of various businesses for holding work piece that will be machined.This mandrel is impeccably produced under the strict bearing of experienced architects utilizing ideal review parts with the assistance of the most recent innovation. Its features are ; 1.High strength 2.Durability 3.Perfect finish

Hydraulic Expansion Gear Grinding Mandrel Jelly Type

Get Price Quote

We offer Jelly Type Hydraulically Expanding Mandrels for gear grinding & shaving.

COLLET TYPE EXPANDING MANDRILS

Get Price Quote

Expandings mandrels are the ideal solution to many working problems by holding parts In the clamping forces are evenly distributed, reducing distortions during part manufacturing process.Mandrels also provide a superior method of holding parts with high volume short cycle times or which require the highest levels of concentricity.Q-Tech precision clampings supply expanding mandrels tailored to your exact specifications. Many different actuation mehod can be use such as drawbar, cantilever nut and front nut.

hydraulic expanding mandrels

Get Price Quote

We are offering hydraulic expanding mandrels. concept-hydraulic clamping systems the advent of concept-hydraulic clamping system opens new ways in mastering the most difficult situation with uncompromising thoroughness. Sophisticated technology, perfect construction and special materials make the clamping devices a generation ahead of the conventional work holding fixtures in clamping force, clamping accuracy and load torque. whereas remarkable technical advance has been made on machines and machine tools, clamping fixtures have scarcely changed. Hence, the available productivity and precision of the machine was not transferred to the component to be machined to a great extent. Concept-hydraulic arbors and chucks offer an optimum solution to this weak link in a machining chain. concept-hydraulic holding devices on the one hand reduce cost and improve quality in almost all areas of machining and inspection while on the other solve the most difficult clamping problems. the very high repeatability and reliability factors reduce rejections to a minimum. There is no deformation of work piece or damage to the clamping surface - though the clamping force is a maximum of 5 kg/mm - as the clamping force is transmitted evenly to the entire clamping surface. This means even very short or thin walled components could be securely clamped with the least danger of canting or deformation. Further more the concentric holding design inherent property provides minimum tir - under 5 microns. Simple actuation reduces mounting and dismounting time - no tapered mandrel, no hammering, no arbor press. Symmetrical mounting allows mounting of several piece parts. concept-hydraulic holding devices have no loose components (collects or liners) making pres¬sure coolant applications on chucks direct and efficient. Presenting of a hydraulic fixture is also simplified as there is no axial move¬ment while clamping. flexibility in design and application of hydraulically controlled holding devices lies in the fact that they can be adopted to perform any machining operation - turning, copy turning, boring, drilling, gear cutting, gear finishing, etc their design can be extended to clamp on blind bores. Splined or threaded bores could be located on the major diameter, minor diameter or pitch-line diameter. concept-hydraulic expanding arbors and chucks could be applied successfully in inspection of components accurately. Many an inspection requirement not possible by mechanical means could be solved by using hydraulic devices. no requirement of additional skill and low maintenance cost are the major advan¬tages of these devices. engineering a selection of arbors and chucks in standard sizes and average bearing lengths are generally available from stock. (write to us for a copy of our standard products catalogue.) in most cases, however, concept tooling is tailored to the specific job in the accuracy range specified. All we need is a print of the part or parts involved with locating surfaces and tolerances indicated. An outline of the operations performed with pertinent machining data or inspection techniques should accompany your enquiry. your enquiry will be carefully and completely analyzed with our recommendations and quotation offered for your consideration. we welcome your specific problem and will be happy to offer our recommendations to suit your requirements.

expanding mandrels

Get Price Quote

We are mmanufacturing all kind of expanding mandrel collet type with manual operated and drawbar operated.

expanding mandrels

Get Price Quote

We offer our hydraulically expanding & contracting jelly filled mandrels, arbors & chucks for gear grinding operation. With use of our products one can achieve high precision clamping & control runout & perpendicularity parameters consistently. This can be used for gear manufacturing industries and is useful for czepel, reishauer, maag, hofler, & wmw. The mandrel is made with split less elastomer steel by manual actuation the sleeve expanded & job clamp rigidly, it gives hi accuracy & reliable performance for long life. Gears always be grind with axial clamping devices, no face clamping is advisable. No face clamping during operation close runout accuracy close perpendicularity gives consistence products output reduce gear noise increase gear life improve in efficiency least maintenance cost → 60° center hole grinded ←

expanding mandrel

Get Price Quote

expanding mandrel

hydraulic expanding mandrel

Get Price Quote

hydraulic expanding mandrel, hydraulic chucks, Hydraulic Equipments

expanding mandrels

Get Price Quote

expanding mandrels, Industrial Tools, Industrial Machinery, collect chucks

expanding mandrels

Get Price Quote

expanding mandrels, Arbors, tap sleeves, revolving centres

Hydraulic Expanding Gear Shaving Mandrels (auto Actuated)

Get Price Quote

We are offering hydraulic expanding gear shaving mandrels (auto actuated). Between centre auto actuated shaving mandrel between centre hydraulic gear shaving mandrels can be manual or auto actuation type. In this type work piece loading is done outside the machine. The work piece is loaded on one half, and then the second half is engaged. in case of manual actuation gear clamping is done manually on one half outside the machine. In auto actuation type after engaging component on one half and the second half of the mandrel, the complete assembly is placed between centres on machine and centring and clamping is performed simultaneously via. Axial pressure of tailstock against gear face. the run out accuracy is below 0.005 mm. machine mounted auto actuated shaving mandrel in this type both halves of mandrel are mounted on opposite work piece spindles. These are suitable particularly for auto robotic loading. the clamping and centring of mandrel is performed same as in case of auto actuated between centre type. the run out accuracy is 0.003mm.

hydraulic expanding mandrels

Get Price Quote

hydraulic expanding mandrels, hydraulic gear shaving mandrels