Fluidized Combustion System

120,000 Per Piece

Husk Fired 1000-15000 Kg/Hr FBC Boiler

2,700,000 Per Piece

1 Piece (MOQ)

Best Deals from FBC Boiler

Fluidized Bed Combustion Boilers

1,000,000 - 20,000,000 Per Piece

1 set (MOQ)

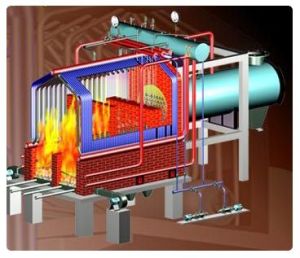

We are engaged in the manufacture, export and supply of Fluidized Bed Combustion Boilers. We use only finest quality material to manufacture these boilers. Our Fluidized Bed Combustion Boilers are preferred for their efficient & trouble free performance. In these boilers, the fuel is burnt in suspension of hot bed material consisting of sand, ash and additives.

fbc boiler

Get Price Quote

1 Kgs (MOQ)

Water wall cum Smoketube Fluidized Bed Combustion Type Boilers

Get Price Quote

Fluidized Bed Combustion Package Boiler

Get Price Quote

Three pass high efficiency Boiler.Over Bed Fuel feeding Rice Husk.Safe Furnace.Large water and Steam space.Longer, Lasting Fluidising nozzles.

fbc membrane water wall steam boilers

Get Price Quote

1000 Kilogram (MOQ)

boiler is mainly cost as per the capacity in kgs /hr and weight 250rs /kg ibr

Fluidized Bed Combustion Boiler

Get Price Quote

Fluidized Bed Combustion Boiler finds wide application in steel, cement, textile and chemical industries for heating different fluids. The salient attributes of our Fluidized Bed Combustion Boiler like Low maintenance cost, best thermal efficiency and easy access to the pressure part make it highly popular among customers. Our company is named among the reputed Manufacturers and Suppliers of Fluidized Bed Combustion Boiler from Maharashtra, India.

Atmospheric Fluidized Bed Combustion Boilers

Get Price Quote

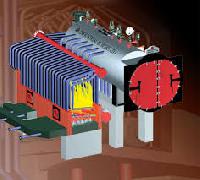

AFBC boilers offer efficient, cost-effective and reliable steam generation. The benefits include fuel flexibility, high efficiency, low emissions, and reduced capital and operating expenses. Our boilers are ideal for burning fuels containing high ash and high Sulphur content. Type of Combustor Air box Open Bottom Hopper Bubbling bed FEATURES Multi-fuel firing options. Optimum combustion with appropriate secondary air system. Machine welded membrane panel. Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory. In bed Evaporator design for better reliability and temperature control Under bed / Over Bed fuel feed system Studded in-bed coils for enhanced heat transfer & reduce erosion. 2-Stage / 3-Stage Super Heater with Inter-Stage Spray type De- Superheater Bottom / Top Supported Design

fbc boiler

Get Price Quote

Built-in Super heater, Choice of Fuel Feeding Systems - In Bed for Coal, Lignite, Saw Dust. - Over Bed for Rice Husk. Bio Gas Compatible, Microprocessor Controlled Fuel Feeder Water cooled, Suvega Tube Water wall. Packaged Concept, Minimum welding at Installation site. No Expansion of tubes

Water Tube Type Bi Drum Fbc Boiler

Get Price Quote

STEAMPOWER is a two-drum water tube boiler from BALKRISHNA. STEAMPOWERcan be used to combust a wide variety of fuels.STEAMPOWER is most suited for applications that require uninterrupted boiler operation even on fuel which have a high fouling tendency. STEAMPOWER can be used for generating saturated steam as well as superheated steam. Superheated steam is used for incidental power generation or cogeneration power in industries such as distilleries, paper, solvent extraction, rice, textiles, etc.STEAMPOWER is available in different combustion systems depending on the fuel. FBC is suitable for burning coal or lignite or other agro-based low-grade fuels Dumping grate or pulsating grate is suited for burning fibrous & moist fuels obtained from industrial waste & agricultural residues Travelling grate is suited for burning low ash fuels - High capacity heating system-Available in different combinations - FBC, Dumping Grate/Pulsating grate, Travelling Grate,- Pulsating Grate- Multi-fuel option - coal/lignite/wood/agro-based fuels/biogas

Vertical Four Pass F.B.C Fired Hot Water Boiler

Get Price Quote

The VFHB-F-series, vertical four pass F.B.C fired hot water boiler For Vertical Boiler, Electrostatic Precipitator, Esp Manufacturers, Indian Boilers designed for maximum efficiency, using a variety of free flow fuels including agro-waste fuels and pulverized coal. It allows required process temperatures at required operating pressures.We are For Vertical Boiler, Electrostatic Precipitator, Esp Manufacturers, Indian Boilers. The combustion system for free flow fuels consists of fuel feeding threw screw feeder handling and stoking equipment, in refractory lined chamber, air and flue gas handling system (including I.D. fan and F.D. fan) with blowers and pollution control equipment. The furnace construction is done on site (only for bricks works)For Vertical Boiler, Electrostatic Precipitator, Esp Manufacturers, Indian Boilers. It includes foundation, fabrication and erection of supporting structure, building up refractory chambers, fixing up firing doors, ash doors, access doors, air plenum chamber and air nozzle. - For fuel such as pulverized coal, rice husk ,sawdust, petcock,- Option of grate/fluidization bad or suspending burning bad.- Easy operation in different type of free flow fuel with maximum efficiency.

fbc boiler

Get Price Quote

We, Triveni Boiler Pvt. Ltd. have established a reputation of renowned Manufacturer, Supplier and Exporter of FBC Boiler (Fluidized Bed Combustion Boiler). In addition to this, we are also a service provider engaged in offering Consultancy Services and Technical Services of Boiler. Cap. Range: 3 TPH to 15 TPH ( Husk / GN Shell / Saw Dust ) 5 TPH to 25 TPH ( Coal / Lignite) Pressure: 10.54 Kg to 21 kg/ cm2 g Type: Water Cum Smock Tube Boiler Membrane Water Wall Panel Lined Radiant FBC Furnace with Shell & Tube Boiler Options: Single & Dual Furnace Manual Firing Cum FBC Firing Over Bed and / or Under Bed Fuel Feeding Fuel Feeding Arrangement Eddy Current Coupling / AC Drive DC Drive Steam Super Heating Salient Features: Very High THERMAL EFFICIENCY Due to Low Combustion Air to Fuel Ratio Higher Combustion Volume & Free Board resulting in efficient Combustion Minimum Radiation Losses due to Membrane Water Wall Panelled Radiant Furnace Minimal Air Leakage in Furnace due to Membrane Panel Higher Effective Heat Transfer Areas Automatic Operation for consistent & uninterrupted steaming Large Water Holding & Steam Space Better Response to Fluctuating Steam Load Superior Membrane Technology in fluidized Bed Combustion Minimum usage fo Refractory in Furnace hence Lower Maintenance & Minimum Leakages Instrumentation & Control For : Safe Operation Easy Operation Optimal Performance

Water Tube FBC Steam Boiler

Get Price Quote

4 Pass design, ensures better heat utilisation & ultimate thermal efficiency. Fluidised Bed Combustion furnace ensures very high combustion efficiency, up to 95% even with fuel, having very high ash & fine contents and having very low calorific value. Straight tube in generating bank enables manual cleaning & easy inspection. The rectangular headers are of welded type box headers with individual opening against each tube at both ends of generating bank. Hence, for cleaning & maintenance of any single tube only single door cap, weighing just 1.5 kg has to be opened. Larger tube diameter in generating bank, i.e. 76.2 mm OD, enables easy manual cleaning. Intermediate tube supports in the generating bank, which prevents tube sagging contributes to higher boiler life. Wide gap in tube spacing i e. 160 mm pitch, prevents inter tube space plugging by soot deposition, which permits trouble free operation without external cleaning as clogging of tube space with soot does not take place. Free floating front header takes care of longitudinal thermal expansion. Hence, thermal stresses are not developed during heating. This design enhances boiler life too. Man hole opening at both sides of the drum for easier access to drum internals. Larger diameter drum coupled with drum internal steam separators ensures dry steam even at full main steam valve opening. Moderately larger furnace area and higher free board height, above grate, makes the boiler capable to burn low grade, high volatill3 & ash contained solid fuel efficiently without reducing rated steam generating capacity. No inventory of spares, since nothing special is employed which is necessary to be procured urgently from us or which is not available in the free market.

Atmospheric Fluidized Bed Combustion (AFBC) Boilers

Get Price Quote

Designed to provide optimum combustion, Uttam's AFBC boilers feature a staged secondary air system. The boilers' multi-fuel firing, uniform temperature distribution and high efficiency make them the ideal choice for power generation.Capacity: 8 TPH to 200 TPH Steam pressure: Up to 110 kg cm2

fluidized bed combustion

Get Price Quote

Feature:- High workmanship. Ease of maintenance. Optimum heat transfer. Great operational safety. Space saving compact design. Regular after sales service.

FBC Boilers

Get Price Quote

FBC Boilers

fbc boiler

Get Price Quote

fbc boiler

Circulating Fluidised Bed Combustion Boiler

Get Price Quote

We are offering circulating fluidised bed combustion boiler. The boiler is a single drum hot cyclonecold cyclone type configurations. Catering mainly to power applications with different fuel combinations particularly suitable for firing high volatileashmoisture fuels, very low cv fuels, nonconventional fuels etc., (100% char, washery reject, petcoke, difficult biomass fuels). The efficiency of the boiler is high (around 88% on ncv) and due to complete combustion the ash will have low loi that makes it suitable for cement production. capacity : 50 to 450 tph pressure : upto 125 kgcm2 sh temperature : upto 540oc application : power generation

FBC Boilers

Get Price Quote

FBC Boilers, Power Plant Equipment, HIGH PRESSURE, Oil Boiler