Fibrillating Brass Ring Roller

10 Per Piece

25 Piece (MOQ)

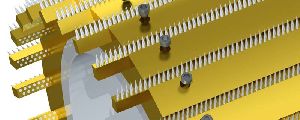

Pinned Brass Rolls

Get Price Quote

10 Piece(s) (MOQ)

We are offering pinned brass rolls. We design, manufacture and supply hot and cold needle perforation rollers. Hot needle perforation rollers cold needle perforation rollers r.k.texparts needle perforation rollers and units are accurate, strong and durable and can be easily added to existing production lines. R.k.texparts micro perforation rollers are manufactured in a range of materials to suit each customers requirements with densities up to a maximum of 600 pins per square inch are available. R.k.texparts pinned perforation parts are suitable for a wide range of applications and can be used in both hot and cold processes. Needle roller design a wide range of standard designs and sizes are available and custom designs can be manufactured according to each customers specific requirements including pinned segments, pinned plates and pinned rollers. Long life pins high quality carbon steel or stainless steel pins are used throughout our production to achieve the maximum lifetime of the product and clean smooth perforation. Accuracy the accurate and uniform pin-point concentric of r.k.texparts perforation rollers ensures even perforation and allows control of the perforation depth from a pin prick to full perforation.

Best Deals from Fibrillating Roller

Retrofitted Fibrillating Rollers

Get Price Quote

With the assistance of our hardworking team, we are able to offer a wide range of quality Retrofitted Fibrillating Rollers. With the aid of our updated transit facilities, we are capable of delivering the orders at requested destinations with ease.

Fibrillating Roller

17,501 Per Piece

fibrillating rollers

Get Price Quote

fibrillating rollers, Steel Pins, Perforating Rollers, stenter pin bars