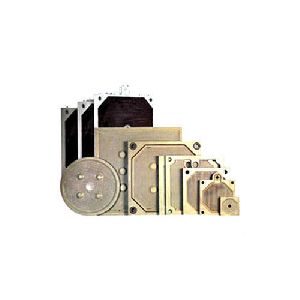

filter press plate

Get Price Quote

100 Piece (MOQ)

With a rich experience of this domain, we hold expertise in offering a vast and exclusive range of Filter Press Plates. These are widely appreciated by our clients due to optimum quality and smooth operations.We test our each product on several parameters to assure zero defects. We use the latest technology to ensure that the results meets the clients desired expectations. Our range is available in different sizes. Moreover, These premium quality products are available in reasonable rates as per clients' specifications and requirement.Features : Leak proof High performance High linkage Long lasting durability Chemical resistive

Lambretta Scooter Air Filter Back Plate

Get Price Quote

We are offering high quality Lambretta Scooter Air Filter Back Plates. These plates have been manufactured in conformity with global standards of quality and safety. Our clients from North America, Southeast Asia, Eastern Asia, Western Europe & Middle East Countries are highly appreciative about the quality, performance and pricing of our Lambretta Scooter Air Filter Back Plate.

Best Deals from Filter Plate

filter press plate

1,050 Per Piece

5 Piece (MOQ)

FRP Filter Plate

Get Price Quote

These FRP filter plates, PP filter plate manufacture are minutely designed and manufactured inputting highest quality of the FRP material with no compromise in the quality to deliver the range of the FRP filter plates that excels in the industries for its excellent toughness, stability and potentiality to perform constantly even under higher filtration pressures. These FRP filter plates are available in the standard specifications, whilst also available in the different size and thicknesses as per the requirement of the end user.

Polypropylene Square & Round Halwa Plate

Get Price Quote

100 Piece (MOQ)

PP Filter Plate

Get Price Quote

recessed filter plates

Get Price Quote

Before making the final dispatch, our entire lot is carefully stored in our capacious warehouse under the administration of experts. Thus, there are minimal chances of defects at buyer's end. We have developed the entire in-house unit wherein we keep our raw material to fulfill variegated requirements of the buyers. Also, we make sure that the material is sourced from the reliable places only.

Membrane Filter Plates

Get Price Quote

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

Plastic White Ceramic Filter Plate

4,800 Per Piece

Lambretta Scooter Air Filter Back Plate

10 Per Piece

Industrial Filter Plates

Get Price Quote

We bring forth a wide range of PP Filter Plates for the clients. These products are available in different shapes, sizes, colors and models as per the requirement and specifications given by the clients. Our products are best suited for filter pressing duties due to their high performance and precision. Moreover, these plates are available at market's leading prices to the clients. Our products are delivered within a stipulated time span to the clients.Features : Low weight filter plates Resistance to corrosion Shortening of the total cycle time Better tightness of a plate pack.

Activated Carbon Filter Plates

Get Price Quote

We provide bonded activated carbon filter plates for air conditioning applications. The use of high quality filter plates for air purification allows easy, dust-free handling, low pressure drops, long lifetimes and air-tight installation, with a facultative polyurethane rim. Standard sized or customized filter plates and complete filter units can be used for the removal of organics, acidic gases and mercury in areas such as airports, electrical and computer rooms, laboratories, dental offices and libraries.

Filter Plates

Get Price Quote

Types of Construction : Recessed Plate and Frame Membrane Plate Caulked & Gasketed Wash - Non wash option Different Feed eye options High Pressure applications Advantages : Less moisture in cake Lesser Cycle time Efficient washing Low feed pressure Higher Filtration Capacity

Membrane Filter Plates

25,000 - 150,000 Per Piece

10 Piece(s) (MOQ)

Filter Plates

Get Price Quote

Avail from Us a Highly Impressive Range of Filter Plates At the Market Leading Price Rates. Our Skilled Professionals Assist Us in Fabricating Filter Plates Which are in Sync with the National as Well as International Demands and Tastes. We Provide Our Clients with Highly Efficient Range of Filter Plates So as to Enhance Their Satisfaction.

Filter Plates

Get Price Quote

We are manufacturers of Filter Base Plates. We manufacture Filter Base Plates, by Forging and Precision Machining process. Details Finishing: Matt Finish. Type: Online T-line

Filter Plate

Get Price Quote

The liquid is directed with the help of pumps through the centre channel of the cartridge from the bottom of the body. Suspended particles get retained on the fitter medium resting on the filter plates and the clear filtrate emerges from the side holes of the plates inside the tank and flows out from the bottom outlet. The filter tank does not come into contact with the liquids and hence remains clean. The cake filtrates and solids remain completely inside the fully closed filter plate cartridge. Complete recovery of the filtrate is possible by passing of air or an inert gas through the bottom inlet to dry the cakes and get a clean empty tank.

Filter Plates

Get Price Quote

We are offering filter plates etc. Polypropylene filter plates are used in filteration plant for filtering the liquid

Industrial Filter Plates

1,500 Per Piece

Filter Press Plates

3,000 Per Piece