Fine Micro Bore Unit

Get Price Quote

100 Pack (MOQ)

We offer micro boring unit or Fine boring unit required for boring tools used on CNC, conventional or special purpose machines of various capacities for machining of fine boring in the metal. We offer micro boring unit in : 0.01 mm least count accuracy 0.005 mm least count accuracy 0.002 mm least count accuracy

vertical fine boring machine

Get Price Quote

1 piece (MOQ)

Best Deals from Fine Boring Machine

Fine Boring Machine

Get Price Quote

Machine CNC Boring & Grooving SPM- Model 810 Component Yoke Operation Boring & Grooving Cycle Time(Outputhr.) 50 Sec.(72hr.)

Fine Boring Unit

Get Price Quote

Fine Boring SPM Machine

Get Price Quote

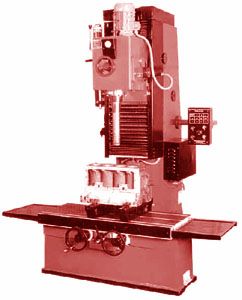

vertical fine boring machine

Get Price Quote

1 Piece (MOQ)

fine boring spm

Get Price Quote

1 Piece (MOQ)

Spcificaton Component specific operation of Boring

Fine Boring Machine

Get Price Quote

Owing to our expertise in this field, we are offering the high-performance Fine Boring Machine. This admirable range finds great application in re-boring of automobile, marine and stationary engines of various sizes. Installed with CBM versions, these machines find application for various milling purposes. These products can be availed at pocket-friendly prices by our valuable clients.

Vertical fine Boring Machine (mi-999)

Get Price Quote

Vertical Fine Boring Machine (MI-999) is precisely designed by our experienced and qualified engineers. It has a six speed gear box that aids it in providing heavy duty performance. Also, the RPM of the machine is as high as 20 to 400. Standard Equipments : Boring tool setting device complete with micrometer One set of paralllel blocks A set of services spanners One spindle fitted with medicine having bore dia.63 to 100mm Two boring tools, one facing tool one chamber tool Clambing jacks Optional Equipments : Tool grinder Spindle 50 to 70 mm V block stand Single cylinder blocks clambing device Specifications Boring Range (with Standard Spindle) 63 to 100 mm Boring Range (with extra Spindle) 38 to 63mm Maximum Boring Depth 300 mm Distance between spindle center to column 165 mm Spindle Speed Range (Normal) 50 to 400 stepless Spindle feeds per Revolution .004", .006" Rapid movement up & down 315 mm Surface of table 300 to 700 mm Table Traverse (Longitudinal) 500 mm Table Traverse (Cross) 25 mm Motor for Spindle RPM 1 HP 1440RPM Delta Type Three Phase, 220 Votls, 50 Hz Rapid Motor up & down 0.5Hp, 2800 RPM, Three Phases 440Votls, 50 Hz. AC Drive (Input) Single Phase 220 Volts, 50 hz (Output) Three Phase, 220 Volts, 50 Hz. Base area ( L x W) 1200 x 920mm Height 1780 Approx. weight 1000 Kgs. Approx. Note : We reserve the right to modify the design & specifications because of continous improvement

vertical fine boring machine

Get Price Quote

We Offer Vertical fine Boring Machine. Innovative High Precision Boring Machine Equipped with modern Technologies, LM Guides, Servo Motors, PLC, Touch Screen

Fine Boring Machine

Get Price Quote

Suitable for Automotive Engine Rebuilding, Boring head travels on Ground Guide Ways protected with bellows, Boring Head fitted with hardened alloy gears to give smooth feel and slide on columns, Mechanical Machine with 2 Speed Motor and Six Speed Gear Box.

Fine Boring Machine

Get Price Quote

The company has marked its presence in the global market as a leading Manufacturer, Supplier and Exporters of Fine Boring Machine (Fine Boring SPM) in Tamil Nadu. Fine Boring Machine is used for US Railway male coupling boring and milling operations. Male Coupling is held firmly with hydraulic clamping. Multi Tool boring head is used for reducing cycle time. Side Milling is done simultaneously with the separate milling cutter. Milling, boring, chip removal, flushing, etc. are automated in Fine Boring Machine. Fine Boring machine is used for highly accurate boring of valve body steering bearing housing. Fine Boring Machine is used to reduce machining cost by sparing HMC. We offer customized packing solution for Fine Boring Machines to our clients. Special Features High precision automatic boring operationMulti tool boring to reduce cycle timeToggle type clamping for holding power brakeBoring and side milling is done simultaneously to reduce the cycle time Technical Specifications Diameter : 10� Bore x 6� Long x ½� x 45o(Both side) Rough Boring Slide : 400 mm St Fine Boring Slide : 300 mm St.Milling Slide : 250 mm St.Hydraulic : Tank 90 liter, Pr.90kg/cm2Rough Boring Spindle : 10HP, 1000rpmFine Boring Spindle : 5HP, 1440rpm Application : High accuracy fine boring for Male Coupling USA Railway Industries Details Size Available : Can be customizedRaw Material Use : Mild Steel and Alloy SteelPurchased By : Sanmar Foundries Limited (Industrial Valve Manufacturers), Viralimalai, Pudukkottai District, Trichy, Tamil Nadu, India.Price : Approximately 25.0 Lakhs

Fine Boring Machine

Get Price Quote

VSimple, easy, fast, economic, this is the best to offer for work, quick clamping easy centering, and best tool setting system. Min & Max. Bore Centre Distance of the Connecting Rod 100 - 350MM, Boring Range 15 to 100MM, Feed 0.6MM, Bottom Part Traverse Crosswise 50MM, Motor Spindle Speed (Dual Speed)0.75-1.0HP.

vertical fine boring machine

Get Price Quote

Fine Boring Machine

Get Price Quote

The machine has been designed to do fine boring of the connecting rod used in the defence sector. The machine has four high-precision spindle units with class ultra-precision bearings which provide accuracy and rigidity to the spindles. The structures of the machine are built by heavily ribbed weldment which provides rigidity and stiffness. The machine is also equipped with high pressure through spindle coolant for achieving the best quality of components. The machine comprises two fixtures mounted on a CNC slide for fine boring the connecting rod. Generally, con rod boring can be completed in several machines. But in this machine, the parent steel bores, bush bores and pin bores are all completed in one machine with three setups. This machine can produce fine bores having taper, cylindricity and ovality of less than 5 microns with very fine surface quality as specified by the customer.

Fine Boring Machine

Get Price Quote

High profile strong design for maximum output with quick & easy operation, it comes with VFD control for spindle RPM fast rapid head up, down also it comes with feed per revolution which cuts of the chances of single running system as both things is controlled by single motor.

Fine Boring Machine

Get Price Quote

Equipments of extra cost: • Boring tool setting device complete with micrometer • Tool holders for boring • Portable grinder with suitable grinding and lapping wheels • Two block jacks • Two sets of parallel blocks 200x600 mm & 120 x 600 mm • Set of spanners • One spindle fitted with machine capacity 65-135 mm

FINE BORING MACHINES:

Get Price Quote

Majority of Commercial Vehicle Manufacturers use our machines. The first EURO 6 Engine manufacturer in INDIA uses our machines for Cylinder Boring. Auto gauging and Tool monitoring to ensure the Process Remains Capable and Stable.

vertical fine boring machine

Get Price Quote

the automatia vertical fine boring machine, model acb 1800, is ideally suited for automotive engines up to 1800mm length. This high precision machine is capable of boring automotive engine cylinders as well as small power tool engines and other industrial components. Rapid up & down movement of the spindle housing & automatic retrieval of the spindle after completion of boring operation using high precision servo motor facilitates turnover of engine blocks. salient features high density graded castings can bore from 32mm to 150mm dia. Up to depth of 500mm feed controlled by servo motor and mpg system fitted with ac drive for continuous spindle speeds form 0 – 700 rpm counter boring is accurate with servo and mpg controls system large work table to accommodate heavy engine blocks easy chip collection facility rapid spindle retraction manual & auto feed for counter boring forced lubrication for inside boring head adjustable stoppers for boring side auto-stop mechanism for spindle traverse dial type tool setting micrometer for accurate tool setting locking for cross slide and table centralised lubrication for all guide ways ergonomically arranged controls with hmi machine is programmable for repeated jobs

vertical fine boring machine

Get Price Quote

Vertical Fine Boring Machine is specially designed for fine and accurate machining of cylinder bores. Manufacturers ensures years of trouble free operation as every phase of manufacturer is under strict quality control. Base and column are of high grade casting. Boring head travels on a Hardened & Grounded finished guide ways column protected with bellows. Boring head is fitted with hardened alloy gears to give smooth feed and side on column. Controls are provided on one side of the machine on a comfortable position and easy operation. The Machine is supplied with the following standard equipment : Boring tool setting device complete with micrometer. Two tool holders for boring. Portable Grinder with suitable Grinding/Lapping Wheels. Two Block Jacks. Two Sets of Parallel Blocks. Service Spanners. One spindle fitted with the Machine, bore dia capacity 64-135 mm.