Flexo printer slotter die cutting with inline folder gluer

30,000,000 - 40,000,000 Per Unit

1 Set (MOQ)

Flexo Printer Slotter Machine

1,450,000 - 1,925,000 Per set

1 Set(s) (MOQ)

Best Deals from Flexo Printer Slotter Machine

Lead Edge Feeder Flexo Printer Slotter Die Cutter Machine

4,000,000 - 4,500,000 Per Set

1 Piece (MOQ)

FLEXO PRINTER & SLOTTER MACHINE

Get Price Quote

Characteristics: • all the electrical appliances adopt domestic excellent products. • all the drive gears are skewed tooth. It adopts high frequency quenching, and part of them are cementite treated. • after milling, grinding and sprinkle lubricating, the driving precision and using life are greatly improved. • the mainframe, blower, phase motor, etc, adopt transducer control. The speed adjusting is steady, and it can save electricity. And it is correct and reliable. • each set has emergency stop switches, which can ensure the safety of the operators. • automatic stacker(option) technical parameter: maximum speed 60 (pcs min) max. Feeding size 1400 x2400 mm skip feeding size 2400 mm max. Printing size 1400 x 2200 mm min. Feeding size 560×260 mm thickness of printing plate 4.97 mm to 7.2 mm printing color 1 color min. Slotting space 210×50×210×50 mm max. Slotting depth 230 mm printing precision ±0.5 mm

Flexo Printer Slotter Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering Flexo Printer Slotter Machine. Flexo Ink Corrugated Paperboard Printing Crasing & Cutting Machine • Carrying paper unit ado pts get-to gether.chain type to carry • paper by hand. • Each machine unit adopts moving by electricity pneumatic • lock tight • It adopts the planet type gear structure The phase • adjustment is fast and precisely Clockwise and anti- • clockwise 360° phase adjustment while revolving and • pausing • Each space adjustment can be displayed digitally on the • scale panel It can be adjusted by hand. • Rubber rollers voluntary rolling equipment to prevent water • ink drying, when stopping • Adjust helical gear transmission All the gears are made • from high frequency quenching • Gears lubrication's are adjusted sprinkled circulation It can • minimize noise and increase gears' using life At the same • time it can also improve the precision of the process • printing • Setting up electric counter 1 can control rightly paperboard • printing numbers • Adjusting pneumatic dividing pump for voluntarily • circulating water ink • 1 can be set up with paper pressing line equipment.

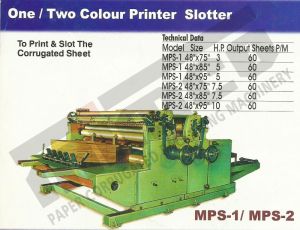

Printer Slotter

Get Price Quote

MIMCO brings this one/two printer-cum-slotter machine to print, crease and slot the corrugated sheet in single pass.

Flexo Printer Slotter Machine

Get Price Quote

Feeding by manually (chain feeding). Printing is done by means of rubber stereo. Stereo can be fixed on printing cylinder by double side adhesive tape.Feeding by manually (chain feeding). Printing is done by means of rubber stereo. Stereo can be fixed on printing cylinder by double side adhesive tape.

Flexo Printer Slotter Machine

Get Price Quote

1 Set(s) (MOQ)

1 Lead edge feeding device A: Lead edge feeder, Feeding precision, speed fast B: Lead edge is making cardboard width front side as fixed position standard , can not be affected by the cardboard cutting width error, Can match the printer, slotter, die cutters fixed position standard requirement. Electric adjusting baffle. C: Have good ability to deal with the cardboard bend D: Have good ability to deal with the thin cardboard conveying. (E and B flute cardboard can feed smoothly.) E: Frequency converter control, according to the cardboard size, bend degree, Convenient fast and smooth. 2 machine platform clutch A: Machine separating and collecting are controlled by button switch, with alarm bell device, Continuous alarm bell to ensure the safety of the operator. B: Pneumatic link locking device, locking secure, convenient, good precision. 3 Feeding roller A: Feeding up roller use wear-resisting rubber , Has balance rectifying, ensure feeding smooth and steady, good precision. B: Feeding down roller use embossing steel roller, hard-chrome plating, wear-resisting, movement balance adjustment. C: Up and down feeding roller use cross-shaped driving micro adjusting device, spanner adjusting, dial showing, adjusting convenient, locking automatically. 4 automatic resetting, zero return device A: Whole machine zero return, press the zero return switch, convenient operation of changing order, shorten the time of changing, reduce the cardboard waste.

Flexo Printer Slotter Machine

Get Price Quote

These inks are meant for use in New-generation High Speed Automatic printers for corrugated application.

ACME Two Colour Board Printer Slotter

Get Price Quote

ACME SingleTwo Colour Board Printer Slotter, Creaser feeding, variable speed drive can be supplied with flexo printing unit. The machine's body is on weels and can be slided easly for setting and cleaning. The speed is approx. 3500 sheets per hour. From single colour or can add on 2nd 3rd colour too. The unit is provided with 4 sets of creaser, 1 set of trimming, 3 sets of slotting and 1 set of cutting dies.

Flexo Printer Slotter Machine

Get Price Quote

It adopt the combination chain-paper feeding style, ensure paper feeding steady, reduce the rate of spoiled products Printing department: Adopt High Quality Anilox Roll and Rubber Roll for High Quality Printing. Adopt push Button controller, adjustment phase directly, adjust quickly and precisely. Adopt electrically separation, pneumatic locking and pneumatic brake. Ink Circulation pump is provided.

Flexo Printer and Slotter Machine

Get Price Quote

Flexo Printer Slotter Machine

Get Price Quote

Computerized control, auto-reset, lack ink alarm Printer rolls grinded surface, cover chrome Arraying suction vacuum for pulling roll, so the Sectional capacity can be adjusted easily to ensure Sheet transfer precise Adjustable speed control system makes change order quickly Doctor blade system is optional. Rubber roll: best inking Dual doctor blades system: perfect spot print. Drying device is optional, it can ensure print quality and Raise production efficiency

Flexo Printer Slotter Combine Machine

Get Price Quote

This machine can process printing, separate, slicing the corner, mark and groove, based on same kind of production. The printing grooving-separating units adopt the type of being electrically and separately locked tightly. Printing roller adopts 360 degree all new design for adopting phase functions. It can adjust the position of printing, slicing and grooving in length-way while revolving and this can save the time of adjustment, better the printing precision and increase production efficiency.

Chain Feed Two Colour Flexo Printer Slotter Machine

Get Price Quote

1.All the electrical appliances adopt domestic excellent products. 2.All the drive gears are skewed tooth. It adopts high frequency quenching, and part of them are cementite treated. 3.After milling, grinding and sprinkle lubricating, the driving precision and using life are greatly improved. 4.The mainframe, blower, phase motor, etc, adopt transducer control. The speed adjusting is steady, and it can save And it is correct and reliable. 5.Each set has emergency stop switches, which can ensure the safety of the operators. Automatic Stacker(Option)

Automatic Chain Feed Flexo Printer Slotter Machine

Get Price Quote

Features all the electrical appliances adopt domestic excellent products. all the drive gears are skewed tooth. It adoptes high frequency quenchine, and part of them are cementite treated. all mining, grinding and sprinkle lubricating, the driving precision and using life are greatly improved. the mainframe blower, phase motor, etc, adopt transducer control, the speed adjusting is steady, and it can save electricity. with auto chain feeding function, it can produce bigger cartons. each set has emergency stop switches, which can ensure the safety of the operators. automatic stacker (option)

flexo printer slotter machines

Get Price Quote

flexo printer slotter machines, Automatic Folder Gluer

Automatic flexo printer slotter die cutter machines

Get Price Quote

Automatic flexo printer slotter die cutter machines