Floatation Tank

Get Price Quote

With sturdy stands that offer high stability, this Floatation Tank is designed by the experts to effectively carry materials from one end to the other. Offering great performance for a long time, our Floatation Tank is highly demanded in the national and international markets.

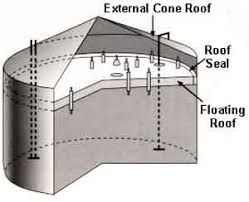

floating roof tank

Get Price Quote

We are offering floating roof tank.

Best Deals from Floating Roof Tanks

Sink-Float Tank

Get Price Quote

Float Application Tanks

Get Price Quote

INDIA’S Leading automotive & industrial Thermoplastic Foam Floats & Floater Manufacturer for the low level Warning & Indication of Fluids stored in reservoirs, used for safety devices such as Hydraulic Automotive Brakes, Engine Coolant & many more other applications. The Foam Floats are manufactured using a State of Art, Registered Patented Process, which allows for consistent Quality & Performance of Floats & Floaters which can withstand under the bonnet, conditions of Temperatures of 140°C ~ -40°C, Pressures of 6 bar & stringent aging test conditions. Hence we provide floats for trouble free performance in the field of applications in such environment like under the Bonnet High Performance Components of Life saving Devices.All such Floats are developed as per customer requirements by satisfying their Specs that is both - Expressed needs & Implied Needs, to provide not only CUSTOMER SATISFACTION but CUSTOMER DELIGHT !The Customer can also provide the data of what is intended out of the need of Float & we have enough expertise to design the part to the entire satisfaction on our own, which is done on so many occasions for our Esteemed Customers many times. FOOD GRADE FLOATS: FLOATS WITH INVISIBLE MAGNET ! Certain Floats are required to be able to perform in drinking water, cold drinks, coffee dispensing machines for which a particular level of liquid needs to be sensed & such Floats need to be ‘FOOD GRADE’ as they are always in contact with such fluids which are consumed by humans. Certain Floats apart from usage of food grade polymer it is desired that the Ferrite Magnet used to activate the reed switch, should not be directly exposed to such liquids which are in contact with the float. By our special designing we have developed the float with invisible magnet wherein the magnet is not visible and is covered by food grade thermoplastic polymer that can withstand a temperature range of -20°C to 120°C & performs well in such dispensers. These Floats with invisible magnet are even exported to European Countries to satisfy the standards prevailing in those nations of FOOD GRADE product. FLOATS WHICH WORK IN TWO LIQUIDS HAVING DIFFERENT PROPERTIES AT A TIME! Thanks to our R&D efforts, by which we have also satisfied our Esteem Customers for a Float which works in a mixture of Two Liquids & one of them unwanted Liquid needs to be discarded which is a continuous process. The Float is used on a device fitted with a membrane which separates out a gathered fluid that is unwanted. For eg: certain automotive have diesel reservoirs being used as fuel, diesel being Hygroscopic attracts moisture (water) which needs to be discarded. The Float is therefore designed in such a way that it works in these Fluids diesel & water wherein it sinks in diesel but floats on water & after a desired signal is generated by the float & Level Switch combination the water is discarded from the reservoir through a valve opening fitted on diesel Reservoir of the passenger car.

floating roof tanks

Get Price Quote

The most vulnerable area on a floating roof tank is the rim seal area. Stored product vapor will collect in the rim and with air it is providing a hazardous mixture. Lightning or sparks can cause a fire to occur. As the fire is hidden by the tank wall, the presence of a detection system is of utmost importance. As it is relatively simple to extinguish an incipient fire, Saval developed a combined detection AND an extinguishing system, built-into one unit. The CFI rim seal protection system is a fully integrated modular system, which utilizes an integral detection system – so no separate detection systems such as electric linear heat detection or separate pneumatic detection tube is required.

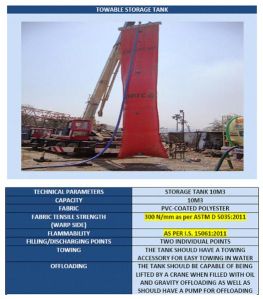

Towable Floating Tank

Get Price Quote

1 Pack(s) (MOQ)

we are offering towable floating tank. material of construction - pvc coated polyester. capacity - 10m3. fabric tensile strength - 300kn as per astm standards

floating roof tanks

Get Price Quote

TankTech is a leading manufacturer of the internal floating roof (IFR). TTA manufactures TECHDECK IFR’s conforming to API 650 Appendix “H” and we exceed API 650 appendix “H” load requirements. Pontoons are extruded and are of greater strength and better quality than other similar design available in the market today. TECHDECK is designed using the latest computer aided design system and high strength, high quality aluminium alloys can supply the strongest lightweight IFR. TECHDECK IFR is continuously reviewed and upgraded based on latest API regulations. TECHDECK is designed for a live load of 750 lbs sq. feet at any point on the deck. Higher live loads to meet specific requirements can also be designed.

floating roof tanks

Get Price Quote

Product Mounted Primary Seal: Installed in contact with liquid by Compressible foam, which is held by holding down arrangement in envelope & the sealing efficiency is very high. Product Mounted Primary seals is more efficient than Vapor seals. Liquid seals can most easily accommodate variations in rim gaps on distorted tanks. The Foam Seal is product mounted and can be used on either external floating roofs or internal pan floating roofs. This seal has been used in tanks from 7.0 M to 92 M in diameter containing the full range of Crude and all type Petroleum products.

floating roof tanks

Get Price Quote

The HMT Mini-Shoe Primary Seal is specifically designed for use with internal steel floating roofs, where tight rim spaces are often encountered. This seal has the same superior long-lasting qualities and positive vapor sealing capabilities as our Scissor Shoe Primary Seal, but is engineered to operate in narrow rim spaces. The innovative feature of the seal is the HMT Mini-Shoe Type Hanger Assembly. It successfully maintains positive gap sealing ability while accommodating rim spaces as small as 2". Made of lightweight galvanized steel or stainless steel, the Mini-Shoe Type Hanger Assembly combines superior strength with economical corrosion prevention. Each HMT Mini -Shoe Primary Seal is designed for a specific tank application and is engineered for rapid field installation. With its wide range of metallic and non-metallic materials, the HMT Mini-Shoe Primary Seal is resistant to virtually all products stored in floating roof tanks.

floating roof tanks

Get Price Quote

Foam System for Storage Tanks, the area in which FIRETECH provide reliable and dependable solutions. With years of sound experience in designing, Manufacturing, In-House and On-site Testing and Commissioning of wide range of Foam System such as :- 1. Base Injection Foam Systems for Conical Roof Tanks. 2. Foam Maker with Vapour Seal Chamber for Conical and Internal Floating Roof Tanks. 3. Foam Maker with Pourer for Floating Roof Tanks. 4. Automatic Rim Seals Foam Protection for Seal Area of Floating Roof Tanks. 5. Medium and High Expansion Foam Systems for Dyke Bund Areas.

floating roof tank

Get Price Quote

floating roof tank, Deaerator Tank, Lt Xlpe Cables, lt pvc cables

floating roof tanks

Get Price Quote

floating roof tanks, column tower

floating roof tank

Get Price Quote

floating roof tank

floating roof tank

Get Price Quote

floating roof tank

Floating Roof Tanks Product

Get Price Quote

Floating Roof Tanks Product

Refinery External Floating Roof Tanks

Get Price Quote

Refinery External Floating Roof Tanks

floating roof tank

Get Price Quote

floating roof tank

Domed External Floating Roof Tank

Get Price Quote

Domed External Floating Roof Tank, Outflow Suction Heaters, heated hoses

Fixed/Floating Roof Storage Tank

Get Price Quote

Fixed / Floating Roof Storage Tank, Gas Pipeline, Water Pipeline Installation

Vertical Floating Roof Tanks

Get Price Quote

Vertical Floating Roof Tanks