Liquid Flow Sensor

Get Price Quote

10 Piece (MOQ)

paddle wheel flow sensor

Get Price Quote

Paddle Wheel Flow Sensor Series PFT Paddlewheel Flow Sensor Non-Magnetic Sensing, Adjustable for 1-1/2 to 40" (38.1 to 1016 mm) Pipe, Pulse or 4 to 20 mA The Series PFT Insertion Paddlewheel Flowmeters are used to monitor liquid flow rates in pipes from 1-1/2 to 40" and is available in brass or 316 SS body. The unit outputs a frequency proportional pulsed or 4 to 20 mA output. The pulse models are a square wave output signal with frequency proportional to the flow velocity and the 4 to 20 mA models have a linear output of the velocity with 4 mA equal to 0 ft/s and 20 mA equal to 25 ft/s. Product Applications Irrigation,Ground water remediation, Cooling systems, Pump protectionLeak detection, Filtration systems ModelDescription PFT-IAN-B111-S-Insertion paddlewheel flow sensor,4-20 mA output, brass body,1-1/2" NPT connection, FKM seals, tungsten-carbide shaft, PTFE bearing. PFT-IAN-S111-S-Insertion paddlewheel flow sensor,4-20 mA output,316SS body, 1-1/2" NPT connection, FKM seals,tungsten-carbide shaft, PTFE bearing. PFT-IDN-B111-S-Insertion paddlewheel flow sensor,pulse output,brass body, 1-1/2" NPT connection, FKM seals, tungsten-carbide shaft,PTFE bearing. PFT-IDN-S111-S-Insertion paddlewheel flow sensor,pulse output,316SS body, 1-1/2" NPT connection, FKM seals,tungsten-carbide shaft,PTFE bearing. Specifications Service:Water-based fluids. Range:1.2 to 25 ft/s (0.37 to 7.62 m/s). Wetted Materials:Body and fitting:Brass or 316 SS;Fitting O-ring:FKM standard, silicone or Buna-N optional;Impeller:316 SS;Shaft:tungsten carbide standard or 316 SS optional;Bearing: PTFE standard. Linearity:±1.0% of FS. Repeatability:±0.5% of FS. Temperature Limits:-40 to 212°F (-40 to 100°C). Pressure Limits:400 psig (27.6 bar) @ 100°F (37.8°C),325 psig (22.4 bar) @ 212°F (100°C). Process Connection:1-1/2" NPT male standard, 2" NPT male optional. Output:> Pulse: NPN open collector with square wave output, rated 60 V @ 50 mA maximum. Frequency: 3.2 to 200 Hz. Pulse Width: 2.5 msec ±25%. 4 to 20 mA: 4 mA is 0 ft/s,20 mA is 25 ft/s. Power Requirement:10 to 35 VDC. Power Consumption:40 mA (max). Electrical Connection:22 AWG shielded UL type PTLC rated 105°C,20'(6.1 m) long with cable gland.Can be extended up to 2000'(609 m) with similar cable.Optional UL listed burial rated cable. Enclosure Rating:NEMA 6P (IP67) *. Housing Materials:Brass or 316 SS. Weight:3 lb. (1.36 kg). Agency Approvals:CE.*Brass units IP67 only. Features Bearings and shaft offer excellent wear protection even in applications with particulate for long life Weatherproof and submersible rated for irrigation applications One unit adjustable over a large pipe size range Multiple wetted material choices offer application versatility Integral 4 to 20 mA output with no need for additional external components Sensor technology uses inductive sensing to sense the blades of the impeller therefor does not use magnets allowing low flow rate monitoring with no concerns regarding magnetic material in the flow

Best Deals from Flow Sensors

Honsberg Configuration Interface

Get Price Quote

10 Piece (MOQ)

Details : Can be used on site for : Parameter modification Firmware update Adjustment of inputs and outputs Can be connected via USB Characteristics : The ECI-3 configuration interface enables connection of GHM HONSBERG sensors to the USB port of a computer. All sensors of the OMNI, FLEX, and LABO families, as well as other sensors which contain a microcontroller are supported. Both 2-wire and 3-wire sensors are supported. In combination with the 'HI-Tools' Windows software, it enables The modification of all the sensor's configuration settings The reading of measured values The adjustment of inputs and outputs Firmware updates Commissioning : The configuration interface is intended for temporary connection to the application. Permanent installation in the system is not intended. The interface is initially connected to the USB port of the computer using the supplied USB cable. The power supply of the interface takes place via the USB port. Additional auxiliary voltage is not necessary at first. The drivers required for operation are provided on the supplied USB stick and are installed in the usual manner. Connection of the sensors takes place at the 'Sensor' port with the supplied M12x1 extension cable. The supplied adapter can be used for connection of sensors with a valve connector. No additional connections are necessary for operation with 2-wire sensors. The supply of sensors and interface takes place from the USB port. Scope of delivery : ECI-3 configuration interface 1.8 m USB cable 500 mm M12x1 extension Valve connector adapter Adapter K04-05 SUB stick with driver software Carry case A mains connector is not included in the scope of delivery.

air flow sensor

8,000 - 9,000 Per Nos

5 Piece (MOQ)

The microbridge mass airflow sensor operates on the theory of heat transfer. Massairflow is directed across the surface of the sensing elements. Output voltage varies in proportion to the mass air or other gas flow through the inlet and outlet portsof the package. The specially designed housing precisely directs and controlsthe airflow across the microstructure sense element. Mechanical design of thepackage allows it to be easily mounted to printed circuit boards.The microbridge mass airflow sensor has a unique silicon chip based on advanced microstructure technology. It consists of a thin-film, thermally isolated bridge structure containing heater and temperature sensing elements. The bridge structure provides a sensitive and fast response to the flow of air or other gas over the chip. Dual sensing elements positioned on both sides of a central heating element indicate flow direction as well as flow rate. Laser trimmed thick film and thin film resistors provide consistent interchangeability from one device to the next.The microbridge mass airflow sensor uses temperature-sensitive resistors deposited within a thin film of silicon nitride. They are suspended in the form of two bridges over an etched cavity in the silicon, shown below. The chip is located in a precisely dimensioned airflow channel to provide a repeatable flow response. Highly effective thermal isolation for theheater and sensing resistors is attained by etching the cavity space beneath the flow sensor bridges. The small size and thermal isolation of the microbridge mass airflow sensor are responsible for the extremely fast response and high sensitivity to flows.Dual Wheatstone bridges control airflow measurement — one provides closed loop heater control, the other contains the dual sensing elements. The heater circuit minimizes shift due to ambient temperature changes by providing an output proportional to mass flow. The circuitkeeps the heater temperature at a constant differential (160°C) above ambient air temperature which is sensed by a heat-sunk resistor on the chip. The ratiometric voltage output of the device corresponds to the differential voltage across the Wheatstone bridge circuit.

AS40-04 Mass Air Flow Sensor

6,000 Per Piece

10 Piece (MOQ)

AS40 features ACT’s third-generation thermal flow die, benefiting from the latest innovations in microfabrication. The sensor die uses a pair of thermopiles to detect changes in temperature gradient caused by mass flow, delivering excellentsignal-to-noise and repeatability. The “solid state” thermal isolation structure on the sensor die eliminates the need for surface cavity or fragile membrane used in competing technologies, making the sensor resistant to clogging and pressure shock. The AS40 series includes the analog output AS40V and the digital I²C output AS40D. The supported max flow rates range from 12 SLM to 300 SLM. The sensors are temperature compensated over the temperature range of 0 to 50 °C. The linearized output provides maximum flexibility and ease-of-use.MAXIMUM RATINGS• Operating Temperature: -25 to 85 °C• Calibrated Temperature Range: 0 to 50 °C• Storage Temperature: -40 to 90 °C• Humidity: 0 to 100% RH, non-condensing• Shock: 100 g peak (5 drops, 3 axis)• Operating Pressure: 25 psi

air flow sensor

Get Price Quote

Flow Sensor Assembly

Get Price Quote

1 Carton (MOQ)

S 401 Thermal Mass Flow Sensor

Get Price Quote

A compressed testing meters S 401 has needed in nearly some compressed air systems. It supports your monitoring systems supports you to optimize your systems and gas management equipments. Pressure Temperature Sensors the compact monitor your compressed air pressure solution with 4 ... 20 mA output. Current CLamp Sensor Rogowski Coil for wide range at high accuracy. Air flowing meters has prepaired to be easily to use for gas management measurements equipments manufacturers with reasonable price, we are offering a many other compressed ait testing products. It’s easily made and chooses the correct flow meter for your suggestions, fit for your requirements. The models are meters, created on its measurements principle it’s not compulsory to reward the air compressed testing equipments, needs any additional measurements installation and measuring the flowing consumptions. As per flowing meters are also suitable for used to gas measurement like nitrogen or several other gases. This S 401 sensors equipment provides you with extraordinary resolutions and sampler rates give exact result and accurate measurements. Our flow meters are capable calibrations curve, owing to these the sensors gas measurements without any damages of precision. We are provided optional colour display has designed to appearance entirely measurement standards that real flow and totally consumptions. At a time we could succeed the sensor setting likes measurement equipments type available. Our company manufacturing two different types of flow meter output signals. It can’t stand prepared with an insulated analogue and positive output signal compressor air testing and the totally compressed air consumptions. Otherwise an edge contact all measurement standards through the digitally interface. Feature Compressed air flow meters Measurement flowing meter and total consumptions Flexible installing for air pressure Two type’s calibrations curve saved sensors in the internal memory We used two different types of gases for sensor IP for industrial environments Pipes diameter to 1” … 12”

air flow sensor

Get Price Quote

1 Piece (MOQ)

We promise to make delivery on time, as we have a wide spread network of logistic service providers and dealers. We make sure the products we offer are as per national as well as international quality standards, reliable and worth every penny spent by buyer.

TSI Mass Air Flow Sensor

20,000 - 26,000 Per piece

1 Piece (MOQ)

TSI's Flow Meter design team can develop the precise mechanical configuration, performance characteristics, and electronic interface you need to optimize your design. The exceptional performance of these embedded flow sensors can enhance your product's performance and improve the time to market on new product development. Specifications Calibration: air Flow range: 0 to 300 standard L/min Accuracy: ±2.5% of reading ±0.1 standard L/min @ 21 °C (Consult TSI for complete product specifications. Specifications are subject to change without notice.) Temperature range: 0 to 65°C Pressure drop: 18 cm H2O at 300 L/min Response time: 5 msec (63% to full-scale flow) Output signals flow: 0 to 4 VDC non-linear, 1 channel Output signal temperature: 0 to 4.5 VDC non-linear Input voltage: 5 VDC ±5%, regulated Power consumption: 0.65 watts at full-scale flow Mating connector: amp 1-640456-0 Eeprom interface: SPI communication Meets RoHS Directive 2011/65/EU Features and benefits Fully calibrated and ready to install Mass flow measurements Fast response Accuracy as a percent of reading Low pressure drop

Honeywell Air Flow Sensor

5,500 Per Piece

Features: Advanced chip design Micro structure technology Enhanced response time Low power consumption Variety of port styles provide greater application flexibility

Oxygen Flow Sensor

Get Price Quote

1000 Piece (MOQ)

Flow Sensor

Get Price Quote

Multi sensor with integrated electronics for flow and temperature measuring of air and gases. Aerodynamically optimized sensor tip without moving parts resultingin widely independent direction characteristics. Active temperature compensation within the overall specified temperature range. Analog output signals for flow velocity and temperature.

paddle wheel flow sensor

5,500 - 25,000 Per Piece

The Rotating Paddle type Flow Sensors are suitable for any clear liquids. There are five types of Sensors with us. PP Flow Sensor- Magnetic (suitable for 6 bar pressure and 60 degree C) SS Flow Sensor- Magnetic (suitable for 10 bar pressure and 100 degree C) SS Flow Sensor- Non-magnetic (suitable for 10 bar pressure and 60 degree C) SS Flow Sensor Flameproof- Magnetic (suitable for 10 bar pressure and 100 degree C) SS Flow Sensor Flameproof- Non-magnetic (suitable for 10 bar pressure and 60 degree C)

ULTRASONIC FLOW SENSOR

Get Price Quote

1 Piece(s) (MOQ)

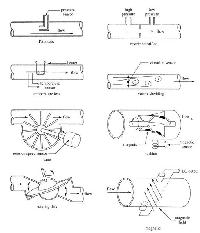

Engineered specifically for small diameter applications, the Mfml Turbine Ultrasonic Flow Sensor provides accurate readings in two flow ranges: 0.3 to 3.8 lpm and 3 to 38 lpm (0.1 to 1 gpm and 0.8 to 10 gpm). The injection-molded PVDF body and ceramic bearings provide excellent chemical compatibility and long service in dosing and batching applications. Union piping and tubing connections along with removable NEMA 4X electronics allow for easy assembly and field replacing ability. The mfml Ultrasonic Flow Sensor can be used with DN8 (¼ in.), DN10 (3/8 in.) DN15 (½ in.) tubing or DN15 (½ in.) piping for simple installation. End connections of the Ultrasonic Flow Sensor are available in PVDF for hose barbs, fusion socket or IR/butt fusion, and in PVC for socket or NPT thread.Fields of Application - Chemical Addition Textiles High-purity Chemical Dispensing Water Addition Fertigation Dosing Pump Protection Advantages - Connection to rigid pipe or tubing unaffected by mounting angles PVDF & ceramic wetted parts provide superior chemical compatibility Low and High Flow rate capability Both clear and opaque fluids Compatible with most flow instrumentation There are many different technologies used in the measurement of flow. The choice of the most suitable type depends on a wide range of factors including the nature and viscosity of the fluid, the flow rate range and the accuracy of measurement required. Types Of Ultrasonic Flow Sensor - Differential pressure flow meters insert an obstruction in to reduce the flow rate and thus the pressure. Flow rate is calculated by taking the difference between upstream and downstream pressures. Positive displacement flow meters capture a liquid sample in a small container and calculate flow rate by counting the number of captures and fills. The rotor in turbine flow meters spins at a rate proportional to liquid flow rate. Variable-area flow meters typically contain a float that is forced upward by the fluid passing through. The point of equilibrium between this force and that of gravity indicates the volumetric flow rate. As a liquid or gas passes through the (usually) bent vibrating tubes of a Coriolis flow meter, the tubes twist to a degree proportional to the fluid’s mass flow. The deflection is measured by a position sensor. Magnetic flow meters operate on Faraday’s law of electromagnetic induction and therefore work only with conductive liquids. A current applied to coils mounted on or outside the flow pipe generates a magnetic field inside the pipe. The liquid passing through generates a voltage proportional to flow rate, which is detected by electrodes on either side of the pipe. Vortex flow meters measure flow by placing a bluff body across the stream. Flow rate is calculated by multiplying the pipe area by the flow velocity, which is proportional to the frequency of the vortices generated by the bluff body. These devices are used with liquid, gas, and steam. Multivariable differential pressure transmitters, when attached to or integrated with a primary element, measure temperature and/or pressure and use these values to calculate mass flow. Thermal flow meters measure mass flow directly. Some of these devices put heat into the flow stream and measure how long it takes to dissipate; others measure the amount of energy required to maintain a constant temperature in the stream. They are used for low flows, primarily gas. Details - Insertion Type Flow Sensor : Differential Pressure Flow Sensors Insertion Type Thermal Mass Flow Sensors : Vortex Flow Sensor Turbine Type Flow Sensors : Ultrasonic Type Flow Sensor

air flow sensor

22,500 Per

Turbine Flow Sensors

Get Price Quote

LP-20 is general purpose flow sensor,Its working rane can be defined according to its nozzle size for low flow range application.With proper installations,sensor achieves better accuracy Special Features:Inlet and outlet on same side,Compact Design. Applications:• Hydraulics• Agriculture• Automobile• Diesel• Wind energy• Food and Beverages• Heavy Engineering• Power• Off Shore

paddle wheel flow sensor

43,008 Per Piece

1 Piece(s) (MOQ)

ULTRASONIC FLOW SENSOR

Get Price Quote

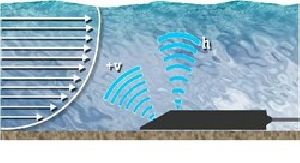

Measuring range h: 0.04 up to 1.3 m with integrated ultrasonic level sensor, expandable with external pressure sensor up to 0-3.5 m Data storage: 2 MB (Q-Eye MII, Q-Eye MDS-5), 2 GB (Q-Eye PSC) Data transmission: integrated GSM/GPRS modem as option for Q-Eye MII external GSM/GPRS modem as option for Q-Eye MDS-5 Q-Eye MII (mobile measurement) The strength of Q-Eye MII lies in mobile applications. The long lifetime of approx. 90 days with a measuring interval of 5 minutes, as well as the small and robust housing make it perfect for temporary measurements. In addition to water level and flow, the quality of signal, battery voltage and calculated velocity are also stored in the data logger. An impulse output provides the necessary signal to a sampler. With the optional connectable pressure sensor, the water level can be collected redundantly. The measuring range can be upgraded up to 3.5m. All connection cables are provided with water tight plugs, which makes mounting or changing of battery in field easy. The display, which is activated with a magnetic switch, shows the active measuring values and informs about the status of the measuring device. With laptop and Software Q-Vision Setup, all parameters are entered and the measured values are read out. Q-Eye MDS5 (stationary measurement). Our discharg measuring system type Q-Eye MDS5 is composed of two individual hardware components the ultrasonic Doppler sensor with measuring signal converter "Q-Eye", as well as the reliable SEBA data logger type "MDS-5" for continuous data storage of for example flow, level and battery voltage. If requested, further digital or analogue sensors (e.g. multi- parameter probe MPS-D3) can be connected. Flow measure- ments in small streams or canals up to approximately 4-5 m width are the ideal application for our Q-Eye MDS5. Due to its very low energy consumption this instrument does not need an external power supply! With a measuring interval of 15 minutes in combination with a 100 Ah battery, a durability of 3 months can be achieved without problems! Good news also for users who are already working with SEBA MDS data loggers: existing operating and evaluation software WEbdien, DEMASvis, DEMASdb or the SEBA HDA can be used continuously without further investments.

RS-900w Polymer Ultrasonic Flow Sensor

Get Price Quote

With a simple design, the RS-900w Polymer Ultrasonic flow sensor is well suited as a long-term replacement for mechanical impeller meters in cold water applications