Emitter Flow Rate Tester

160,000 Per Unit

1 Unit (MOQ)

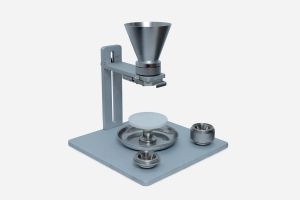

Powder Flow Tester

10,000 - 45,000 Per Piece

1 Piece (MOQ)

A quality control application tool widely used to test the porosity of a wax-coated metallic vessel in the labs. The container can be an aluminium tube, can or a bottle cap. To measure porosity of a tube means to conclude whether the wax coating has holes or spaces in it that possibly trap air or allow liquid through it. The apparatus uses DC potential, a copper electrode and chemical solution to test the porosity that can be read through a digital display on the device. It is an easy and accurate method to know whether the lacquer coating is continuous or has any pores in it. Raise Lab offers user-friendly and easy to operate Lacquer porosity testing apparatus that is as accurate as any other imported equipment. Introducing the RPF-1 Powder Flow Tester: Precision in Powder Flow Assessment The RPF-1 Powder Flow Tester redefines accuracy in measuring the flow properties of powder samples. Crafted to meet the stringent requirements of USP Chapter 1174 and Ph. Eur Chapter 2.9.36, this cutting-edge apparatus stands as a pinnacle of reliability and precision. Advanced Features: Enhanced Hygiene: Designed for easy cleaning and contamination-free operations, ensuring impeccable results with every test. Minimal Maintenance: Enjoy a service-free experience, allowing you to focus on your assessments without interruptions. Adherence to Standards: The RPF-1 complies with both USP <1174> and Ph. Eur (2.9.36) standards, ensuring that your results meet globally recognized criteria. Stainless Steel Craftsmanship: All components are meticulously manufactured in stainless steel grade 316, a testament to durability and quality. Stability in Design: The unique design is engineered for a vibration-free base platform, contributing to accurate measurements. Versatile Testing: Utilize interchangeable stainless steel cones tailored to your testing requirements, offering flexibility without compromise. Precision at Your Fingertips: Opt for the Digital Height Gauge with NABL Calibration Certification (optional) for precise measurements. Calibration Assurance: Choose the optional Stop Watch with Calibration Certificate to enhance the accuracy of your assessments. Comprehensive Package: The apparatus arrives with a cleaning brush, ensuring that you’re well-equipped for meticulous maintenance. Seamless Sample Handling: Included is a Stainless Steel Scoop, providing convenience when pouring test samples. Technical Excellence at a Glance: Crafted for Precision: Designed to measure Angle of Repose and Flow-Through an Orifice (Funnel) Attachment. Stainless Steel Dominance: All parts manufactured in stainless steel grade 316, guaranteeing longevity and resilience. Versatility in Cones: Interchangeable stainless steel cones cater to diverse testing needs. With the RPF-1 Powder Flow Tester, you gain more than an instrument – you obtain a precise tool to decipher powder behavior. Whether it’s adherence to global standards, ease of use, or a focus on accuracy, the RPF-1 stands ready to elevate your powder flow assessments. Say hello to a new era of reliability in powder testing.

Best Deals from Flow Tester

Computerised Melt Flow Index Tester

Get Price Quote

1 Piece (MOQ)

To determine Melt Flow as per ASTM D1238 – “A”, “B” & “A + B”- METHOD & ISO 1133 Fully Computerised/Touch Screen. Other Standard Model is also available. This instrument measures the rate of extrusion of Molten resins through a die of specified length and diameter under prescribed conditions of temperature, load, piston position. SPECIFICATION Instrument with following accessories will be supplied Digital stop watch, Temp. Controller ( PID ), Piston, Orifice remove, Barrel Cleaner, Orifice Cleaner, Scoop, combined weight of 2.16 Kgs.. and 5.0 Kgs.Max.

flow testers

Get Price Quote

Item Code : PROVASETT3FThis category includes the equipment for the testing of products that must assure a predetermined flow rate. The test is performed using instruments with massive flow sensors. Reckoned amid one of the distinguished organizations, we are affianced in providing a world class assortment of Flow Tester, PROVASET T3F. Developed and manufactured at par with the norms and quality standards lay down by the market, these provided testers are available with us in varied specifications and altered options. Along with this, for their consistency and high functionality, these are highly acclaimed.Features : Direct flow measurement PLC interface RS485 and USB serial lines Reliable Customizable fullscale range and resolution Low maintenance Longer life Provaset T3F is an electropneumatic instrument designed for open-air flow tests at programmed pressure, controlled by an electronic pressure regulator. Provaset T3F can be managed manually by an operator or automatically, via PLC with digital inputs and outputs or remotely via a PC with serial interface. This model is suitable for use in all industrial segments, on testing benches, production lines or fully automated systems.Provaset T3F instruments are designed for quick tests, by measuring the flow rate of air through the product being tested at a well-defined pressure; models with a bypass circuit are available for a quicker filling of the product being tested.The pressure drop due to air flowing in the piping and connections to the component being tested can be compensated by reading pressure directly on the component being tested, with a separate connection independent from the passing flow.Main features of PROVASET T3F are : Flow measurements with mass sensor (mass flow) Full scale from 50 cm3/min to 300 l/min Resolution from 0.01 cm3/min to 0.1 l/min Test pressure: 1 bar - 10 bar, electronic regulation Pressure measurement: 1 Pa - 10 Pa resolution Automatic compensation of measured flow to test pressure Quick testing for filters, valves, taps, passage holes, discharge manifolds... Safety valve testing with measurement of peak opening and sealing pressures 50 test tables Serial Line RS485/USB for connected to PC, PLC o HMI Virtual Instrument (driver) for National Instrument LabView available

Melt Flow Index Tester

Get Price Quote

1 Piece (MOQ)

Melt Flow Index Tester

Get Price Quote

Mass Air Flow Tester

240,000 Per Piece

1 Piece (MOQ)

Flow Tester

Get Price Quote

We provide our clients with compact type "all-in-one" air flow tester, the features are as follows: features: full dot led screen with back light displays numerous information basic set-up function allows easy setting bar graph can hold up to 1000 data. Compensation sampling data graph is also included, useful for quality control wide flow range from f.s.500ml/min to 100l/min and traceability available mass flow sensor used for flow sensor.

Melt Flow Index Tester

Get Price Quote

The melt flow tester, built according to International standards, is an instrument for measuring with great accuracy the "Melt Flow Rate" and useful for quality control test on flow ability, grading of thermoplastic material according to flow In general, useful for predicting adequacy of thermal stability case of processing and quality of molding

Powder Flow Tester

Get Price Quote

Quick and easy powder flow analysis is now possible with the Powder Flow Tester provided by us. Whether you need to predict powder flow in R & D for new formulations, or perform a QC check on incoming materials and final products, the Powder Flow Tester offered is best in terms of both quality and pricing. We have established a track record for supplying top quality Powder Flow Testers.

Melt Flow Index Tester

45,000 - 150,000 Per Piece

1 Piece (MOQ)

Melt Flow Index Tester

Get Price Quote

The most precise instrument for the measurement of Melt Flow Rate (MFR) or melt volume rate (MVR) in quality control and research applications. The LMFI 5000 is the first melt flow indexer to utilize a powerful 32-bit microprocessor to provide test parameter control, self-diagnostics and digital calibration. The onboard computer controls and displays temperature to ±0.1°C using a unique PID control algorithm. Four melt indexer models are offered in the advanced Dynisco LMI 4000 series, each with features designed to meet specific application requirements.

Melt Flow Index Tester

5,000 Per Piece

Manual Powder Flow Tester

Get Price Quote

Melt Flow Index Tester

Get Price Quote

We source the required raw material from the certified places after complete quality confirmation. As a result of which, the finished products comply with elevated industry standards. Buyers are free to place orders and can expect timely deliveries of the same. STANDARDS : All Indian Standards, ASTM, DIN, BS Standards and many other equivalent Standards. APPLICATION : M.F.I Tester is used to measure the flow rate of different Polymers. The generated values helps to distinguish the different grades of Polymers. Because of the fact that plastic materials are seldom manufactured without incorporating additives, which affect the processing characteristics of material like stability and flow ability. USP : HEXA PLAST provides Melt Flow Indexer with customized controller keeping in mind the process of test. Precise Temperature with accuracy of + 0.1º C. Microprocessor based digital timer with facility to select number of test, cutter time, buzzer indication on completion of test and advance buzzer indication for manual cutting procedure. Fully Automatic MFI is having facility to conduct to test independently by pre-setting the temp. of test, time & applying the required Load and it will directly give the result of MFI for individual test & average of all test. Determination of melt flow index of thermo plastic materials Definition : Melt flow index is defined as the rate of extrusion of molten resin under specified temperature and pressure through a specified size of die in 10 minutes. It is expressed in g/10 min. MFI Tester capable of maintaining tem. From ambient to 350°C Principle & Significance: This characteristic is primarily useful for measuring uniformity of flow rate of materials. This is used for grading of Thermoplastic material and their quality control i.e. in determining lot-to-lot consistency of resin. A material having high molecular weight has more resistance flow than the flow molecular weight polymer.

Flow Tester

500,000 - 600,000 Per piece

Flow measurement with solid-state sensor T8730 was designed for the precise task of measuring flows on parts such as filters (medicinal, diesel or petrol), tubes, nozzles, openings and valves. Other than the classic flow measurement, the instrument also has other ways of making it as versatile as possible in its category: ascent and descent ramps, opening tests and burst testing. Another separate function is the "continuous measurement", i.e. a test with infinite times allowing adjustment of the taps and part repairs in real time. The tool also avails of an intelligent pressure adjustment, which uses the automatic pressure regulator to continuously adjust the test pressure based on the variation in load loss, to ensure the reading is as stable and repetitive as possible. Solid-state sensor Multiple operating modes Intelligent pressure adjustment Limitless connectivity. The new T8730 equipment includes ports for the USB slave, RS232, RS485, Profinet, EtherNet IP and EtherCAT. Assembly may also include an optional Ethernet port and a 26-pole connector with 4 inputs and 8 outputs, which are completely programmable, for interfacing with the external valves, safety barriers, switches, etc... The front panel has a master USB port for connection to a USB key to save the tests conducted, backup/restore parameters and upgrade tool firmware. The connection to thermal printers, barcode/data-matrix readers and markers takes place automatically using an internal menu. Usb key High power outputs RS232, RS485, Can, TTY Ethernet and auxiliary connector Top category technology. We decided not to make compromises when equipping the T8730, assembling the best components currently on the market, such as the piezoelectric electronic regulator which guarantees stable and repetitive adjustment, or the solid-state sensor with a vast reading range, or the specific valves for this model, with a life estimated in tens of millions of cycles. All these advantages give never before seen precision performance, stability and accuracy. Measurement resolution starts with 0.1 cc/min based at the bottom of the scale, varying from 1,000 to 20,000 cc/min, with maximum pressure of 2 bar. Automatic pressure regulator Measurement up to 20,000 cc/min Resolution starting from 0.1 cc/min Made to measure pneumatic section. To avoid overheating due to long activation times of the filling circuit, we have designed particular, high capacity pneumatic valves, which not only work in hot temperatures, but also quickly fill the piece being tested, making the T8730 also suitable for testing on parts with significant volumes. All of the above, while maintaining ForTest's historic reliability. Heat-proof pneumatic valves High filling speed No periodic maintenance Innovative design. What appears to be a simple design exercise, in fact hides an in-depth study to make use and understanding of the equipment as simple as possible. The front panel is made of a single sheet of tempered glass and aluminium, which makes it extremely easy to clean, making the T8730 suitable for use in the laboratory and on the production line. The extensive internal menus are easy to understand and the graphic interface was designed to only display important information. Everything is exactly where it should be. User-friendly interface Easy to clean Use in sectors at 360°

Melt Flow Index Tester

Get Price Quote

The Melt Flow Index (MFI) is a amount of the effortless flow of the melt of a given thermoplastic polymer. It is defined as the weight of polymer in grams flowing in 10 min through a die of specific diameter and length by a pressure applied through a known weight at a controlled temperature.

Melt Flow Index Tester

44,000 - 48,000 Per Piece

1 Piece (MOQ)

Melt Flow Index Tester

40,000 - 62,000 Per Set

Melt Flow Index Tester

Get Price Quote

We offer a wide range of Melt Flow Index Tester widely used to determine the melt flow index of plastic material. This system is structured with a heated extruder tube, an interchangeable jet and a piston with dead weights. This piston is used to apply the required pressure on the material inside the carbon steel extruder tube. A Bend Heater is affixed around outer circumference of the extruder tube and is used as an effective heating material. This heater is covered with a mineral wool insulation. The extruder tube is installed with a PID controller to indicate & control the temperature. Manufactured in accordance to the ASTM D 1238 & equivalent standards, this range of testers is available in various models with different parameters.Construction of the metal flow index tester: The assembly is fixed on a rigid stand. The bottom of the tube is lagged with an insulation of PTFE to prevent sticking of the extrudate The jet through which the extruder is pushed out is made from hardened and ground die steel The piston made from silver steel relieved at the upper end is provided to push the extrudate out of the jet. The piston moves inside the cavity of tube. A sleeve to provide to guide the relieved portion of the piston The plate-form is thermally insulated from the load. The extruder tube assembly is mounted on a metal box. A sheet metal control panel is mounted on the side of the equipment & houses the PID Controller, digital preset timer & other electronic components. Cleaning tools for tube cavity, jets, stoppers and cutters for the extrudate are also available with the equipment. The top of the piston carries a plate-form for keeping the load on.

Melt Flow Index Tester

42,000 - 60,000 Per one

1 Unit (MOQ)

Limited Oxygen Index Apparatus

Get Price Quote

1 Piece (MOQ)

Melt Flow Index Tester

Get Price Quote

1 Piece(s) (MOQ)

As a reliable name, we ensure that payment procedures remain secured with us. For this, we issue invoice to the customers stating the products, quantities and agreed prices. The material required for preparing quality-centralized product range is sourced from the trusted places and that too after complete quality confirmation.

Melt Flow Index Tester

Get Price Quote

With our modern transportation facility, timely and safe deliveries are guaranteed with us. With the assistance of our safe and automatic warehousing system, we are able to store the entire lot of products in a secured manner. The entire lot is cross checked at regular basis for ensuring complete safety of the products.

Limited Oxygen Index Apparatus

Get Price Quote

Oxygen index is defined as minimum concentration of oxygen, expressed as volume percent in a mixture of oxygen and nitrogen that just support flaming combustion of plastic materials under equilibrium condition of candle like burning. The equilibrium is established by the relation between the net lost to the surroundings as measured by either time of burning or length of specimen burned. This point is approached from both sides of the critical oxygen concentration in order to establish the oxygen index. The “ASIAN” Limited Oxygen Index Apparatus consist of a test chimney made of borosilicate glass (size is 76mm internal diameter & 450mm long) suppurated by the metallic base and hook with the help of the metallic pillar. The mixture of nitrogen and oxygen is released from the bottom of tube. The tube is filled with glass beads for mixing and evenly distributing the gas mixture. The specimen holder, which holds the test specimen, made of U shape and fixed at the center of the chimney. There is the porous screen mounted below the level of the specimen holder, to prevent falling combustion debris from fouling the gas entry and distribution paths. There is a digital temperature indicator cum controller with thermocouple for the measurement and control the temperature within the chimney. A copper tube with suitable orifice for pilot flame is provided for igniting the specimen by inserting it from the top of the test column. The digital preset timer and buzzer is also mount in the instrument. Two Rotameter with needle valve are provided to control and measure oxygen and nitrogen flow in the test chimney. A timer for indicating the time of burning with a reset switch. The rotameter, temperature controller, timer are fitted in the sheet panel. The test chimney is fitted separately on the metallic platform. Flow Meter (Rotameter) : 10 to 90 cc/sec for Oxygen × 2cc/sec 30 to 270 cc/sec for Nitrogen × 10cc/sec Note : Item Required By The User For Complete Testing: Oxygen gas, nitrogen gas and LPG cylinders with its regulator and fitting, 220 V single phase power supply (Other Power optional).

Melt Flow Index Tester

51,000 - 55,000 Per Unit

01 Piece (MOQ)

melt flow tester

Get Price Quote

The manually operated test procedure is very simple to undertake. Molten Polymer is extruded through a closely controlled orifice (die)from the apparatus using pre set conditions of temperature and pressure produced by a dead weight system. The extruded polymer is cut off manually and is then weighed. Using the time interval to extrude the polymer its flow rate over 10 minutes can easily be determined, thus giving the Melt Flow Index (MFI) or Melt Mass Flow Rate (MFR) in g/10 min. By conducting a simple Density Test at test temperature on the same material using the same pre set conditions and a known piston travel distance the Melt Volume Rate (MVR) can also be determined.The 6MBA Melt Flow System is supplied as standard with a replaceable hardened steel cylinder liner, standard test die and piston along with 2.16 kg test load and cleaning ancillaries. The temperature controller used is a 16th DIN type and displays the current temperature and set point and is accurate to 0.1 deg C. A PT100 Platinum Resistance Thermometer is used to accurately control the temperature of the barrel. The maximum allowable temperature variation along the length of the cylinder liner is in accordance with ISO1133 International Test Standard. An integrated timer is also fitted to accurately time the extrusion of the material in seconds to enable you to calculate the Melt Mass Flow Rate (MFR). All documentation is supplied including a product user manual and a fully traceable calibration certificate.Optional weights can be supplied to cover all testing parameters to International Test standards and for the heavier weights the optional weight loader can fitted to the apparatus for ease in loading the piston. The weight loader can also be used as a hold back feature for materials which have a high flow rate. The 6MBA is the basic model offered within the Ray-Ran Range of Melt Flow IndexersThe manually operated test procedure is very simple to undertake. Molten Polymer is extruded through a closely controlled orifice (die)from the apparatus using pre set conditions of temperature and pressure produced by a dead weight system. The extruded polymer is cut off manually and is then weighed. Using the time interval to extrude the polymer its flow rate over 10 minutes can easily be determined, thus giving the Melt Flow Index (MFI) or Melt Mass Flow Rate (MFR) in g/10 min. By conducting a simple Density Test at test temperature on the same material using the same pre set conditions and a known piston travel distance the Melt Volume Rate (MVR) can also be determined.The 6MBA Melt Flow System is supplied as standard with a replaceable hardened steel cylinder liner, standard test die and piston along with 2.16 kg test load and cleaning ancillaries. The temperature controller used is a 16th DIN type and displays the current temperature and set point and is accurate to 0.1 deg C. A PT100 Platinum Resistance Thermometer is used to accurately control the temperature of the barrel. The maximum allowable temperature variation along the length of the cylinder liner is in accordance with ISO1133 International Test Standard. An integrated timer is also fitted to accurately time the extrusion of the material in seconds to enable you to calculate the Melt Mass Flow Rate (MFR). All documentation is supplied including a product user manual and a fully traceable calibration certificate.Optional weights can be supplied to cover all testing parameters to International Test standards and for the heavier weights the optional weight loader can fitted to the apparatus for ease in loading the piston. The weight loader can also be used as a hold back feature for materials which have a high flow rate. Please be aware that this machine has no computer connectivity or file capture software functionality.Although the MFR value is not a fundamental property of the polymer, it does however, give an indication of the flow characteristics of the polymer and it has become one of the most widely used references for the quality control of polymers.Technical Specification Technical Specification Digital Temperature Controller Large Twin Colour Display Easy Set Point Operation Temperature Accurate to +/- 0.1°C Temperature Range 0 to 400°C Temperature Resolution +/- 0.01°C Digital Timer - Large easy to read display Test Die, Piston & 2.16kg Test Weight supplied as standard Filling and cleaning tools included as standard Conforms to method A of the ASTM standard Count Range - 1 second to 99999 hours 59 seconds (8 character display) Electrical characteristics: 110v@60hz and 220v@50hz – fuse rating: 10amp Optional Ancillaries Weight Loader Full Range of Test Weights Available from 1Kg to 21.6Kg Hastalloy cylinder liner, Piston and Die for corrosive materials

Melt Flow Index Tester

Get Price Quote

Manufacturers & Exporters of Melt Flow Index Tester Melt Flow Index Tests measures the rate of extrusion of a thermoplastic material through an orifice of specific length and diameter under prescribed condition of temperature and pressure. This test is used as a means of measuring the uniformity of flow rate of the material. With the help of this test we can distinguish between the different grades of polymer. Specification : Temperature Controller : Microprocessor based Digital temperature Controller with range up to 400°C, resolution up to 0.1°C & accuracy of ±0.1% F.S.D. Timer : Microprocessor based Digital Timer with range up to 999.9 seconds and having preset facility and buzzer output. Weights : 2.16 Kg & 5 Kg hard chrome plated weights. Accessories : Orifice, Piston, Material charger, Barrel cleaner, Orifice cleaner, Sample Cutter. Paint : Powder Coated. Power : 230V AC.

Melt Flow Index Tester

Get Price Quote

The Melt Flow Index Test measures the rate of extrusion of a Thermoplastic material through orifice of Specific Length and Diameter under prescribed conditions of temperature and pressure.Fully Automatic MFI is having facility to conduct to test independently by pre-setting the temp. of test, time & applying the required Load and it will directly give the result of MFI for individual test & average of all test.Melt Flow Indexer is used to measure the flow rate of different polymers. The reported Melt Index values helps to distinguish between the different Grades of Polymers. This is due to the fact that plastic materials are seldom manufactured without incorporating additives, which affect the processing characteristics of material like stability and flowability.

ELECTRONIC LEAK AND FLOW TESTERS

Get Price Quote

We manufacture state of the art low cost Electronic Leak and Flow Testers. Our leak testers can be used for testing automotive / pneumatic / hydraulic / medical components. We also design and manufacture complete leak testing machines as per customer requirement.