2 TPH Fluidized Bed Combustion Boiler

1,000,000 Per Piece

1 Piece (MOQ)

Atmospheric Fluidized Bed Boiler

Get Price Quote

1 Piece (MOQ)

Best Deals from Fluidized Bed Boiler

Fluidized Bed Combustion Boilers

1,000,000 - 20,000,000 Per Piece

1 set (MOQ)

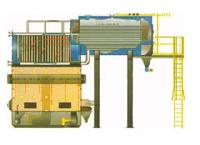

We are engaged in the manufacture, export and supply of Fluidized Bed Combustion Boilers. We use only finest quality material to manufacture these boilers. Our Fluidized Bed Combustion Boilers are preferred for their efficient & trouble free performance. In these boilers, the fuel is burnt in suspension of hot bed material consisting of sand, ash and additives.

Fluidized Bed Combustion Package Boiler

Get Price Quote

Three pass high efficiency Boiler.Over Bed Fuel feeding Rice Husk.Safe Furnace.Large water and Steam space.Longer, Lasting Fluidising nozzles.

Water wall cum Smoketube Fluidized Bed Combustion Type Boilers

Get Price Quote

Fluidized Bed Combustion Boiler

Get Price Quote

Fluidized Bed Combustion Boiler finds wide application in steel, cement, textile and chemical industries for heating different fluids. The salient attributes of our Fluidized Bed Combustion Boiler like Low maintenance cost, best thermal efficiency and easy access to the pressure part make it highly popular among customers. Our company is named among the reputed Manufacturers and Suppliers of Fluidized Bed Combustion Boiler from Maharashtra, India.

fluidized bed combustion

Get Price Quote

Feature:- High workmanship. Ease of maintenance. Optimum heat transfer. Great operational safety. Space saving compact design. Regular after sales service.

Shanti Fluidised Bed Cumbustion Boiler

Get Price Quote

A Fluidized Bed Boiler popularly known as FBC Boilers are designed so as fuel particles are suspended in a hot, bubbling fluidity bed of Refractory Bed materials , through which jets of air are blown to provide the oxygen required for combustion . The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC Boilers plants are capable of burning a variety of low-grade solid fuels, including most types of coal and woody biomass, at high efficiency . In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace Boilers , so may offer significant advantages over the latter in terms of cost and flexibility. Construction FBC Boilers has a water-wall type construction has a steam-water natural circulation system for heat exchange. Vertical in-bed heat exchange tubes are provided and the steam drum of the boiler extends across the full length of the boiler combustion chamber and the convection heat exchange chamber. An air distributor grate is provided for introduction of fluidizing air into the combustion chamber and the air flow therefrom can be controlled to afford a flexible turn-down capability. Model Name : “ Shanti EF-MW-FBC Boiler “ Model No : “ SB-EF-MW-FBC Series Fuels : Husk , Coconut & ground nut shells , Imported Coal , Pulverised Coal Capacities Evaporation capacity : 2000 kg/hr. To 15000 kg/hr. Working Pressure : 10.54 kg/sqcm to 44 kg/sqcm Firing Mode : Automatic Features Wih through combustion due to fluidisation the efficiency is high when compalred to conventional Boiler Fully Automatice right from fuel firing to Ash removal Easy access of maintenace and tube cleaning Balanced draft design for efficient combustion of fuel in furnace Cost Effective in larger capacity Boilers Use of superier quality valves and fittings ensure durability and negligible maintenace Applications Suits all medium and large process industries like Par-boiled Rice Mill , Chemical and pharmaceuticals , co-gen plants , DC Mills , Paper Mills , Textiles , and other process industries where steam requirement is above 2000 Kgs / Hour.

fluidized bed boiler

Get Price Quote

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels. A bed of solid particles is said to be fluidized when the pressurized fluid (liquid or gas) is passed through the medium and causes the solid particles to behave like a fluid under certain conditions. Fluidization causes the transformation of the state of solid particles from static to dynamic.

Fluidised Bed Steam Boilers

Get Price Quote

Features The specially designed fire cum water wall in the Fluidised Bed Steam Boilers reduces radiation losses through conventional external furnace Steam Boilers. This improves overall efficiency of the Fluidised Bed Steam Boilers. Reduces work at the boiler site. Reduces civil works and initial capital cost incurred at the Boiler House. Easily convertible to any type of fuel.

fluidized bed boiler

Get Price Quote

RRIPL’s Refractory Bed Material for boilers of Low Ferric High Temperature Super Quality is made out of high quality refractory aggregates of high alumina contents & dense texture. Unlike other bed material manufacturers we use raw material which limits the clinker formation. RRIPL’s this very special Bed Material has many special characteristics that made it a perfect material for obtaining smooth and perfect fluidization use in Fluidized Bed Combustion Boilers (FBC) and Circulating Fluidized Bed Combustion Boilers (CFBC).

Atmospheric Fluidized Bed Combustion (AFBC) Boilers

Get Price Quote

Designed to provide optimum combustion, Uttam's AFBC boilers feature a staged secondary air system. The boilers' multi-fuel firing, uniform temperature distribution and high efficiency make them the ideal choice for power generation.Capacity: 8 TPH to 200 TPH Steam pressure: Up to 110 kg cm2

Atmospheric Fluidized Bed Combustion Boilers

Get Price Quote

AFBC boilers offer efficient, cost-effective and reliable steam generation. The benefits include fuel flexibility, high efficiency, low emissions, and reduced capital and operating expenses. Our boilers are ideal for burning fuels containing high ash and high Sulphur content. Type of Combustor Air box Open Bottom Hopper Bubbling bed FEATURES Multi-fuel firing options. Optimum combustion with appropriate secondary air system. Machine welded membrane panel. Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory. In bed Evaporator design for better reliability and temperature control Under bed / Over Bed fuel feed system Studded in-bed coils for enhanced heat transfer & reduce erosion. 2-Stage / 3-Stage Super Heater with Inter-Stage Spray type De- Superheater Bottom / Top Supported Design

fluidized bed boiler

Get Price Quote

fluidized bed boiler, agro waste fired boiler, Coal Fired Boiler

Fluidized Bed Combustion Boilers

Get Price Quote

Fluidized Bed Combustion Boilers, condensing steam turbines

fluidized bed boilers

Get Price Quote

fluidized bed boilers, agricultural waste fired boilers, Steam Boilers

Fluidized Bed Combustion Boilers

Get Price Quote

Fluidized Bed Combustion Boilers, Coal, waste refractories material

fluidized bed boilers

Get Price Quote

We are offering fluidized bed boilers. The ibl group is a research driven, industrial organisation specialising in design and manufacturer of process steam boilers, industrial boilers, power boilers, turbines, mini power plants, specialised combustion solutions, autoclaves and vulcanisers, solar thermal systems, esp, bag filters and pollution control equipments.

fluidized bed boilers

Get Price Quote

Sitson is offering a wide range of fluidized bed boilers in india.

Circulating Fluidised Bed Combustion Boiler

Get Price Quote

We are offering circulating fluidised bed combustion boiler. The boiler is a single drum hot cyclonecold cyclone type configurations. Catering mainly to power applications with different fuel combinations particularly suitable for firing high volatileashmoisture fuels, very low cv fuels, nonconventional fuels etc., (100% char, washery reject, petcoke, difficult biomass fuels). The efficiency of the boiler is high (around 88% on ncv) and due to complete combustion the ash will have low loi that makes it suitable for cement production. capacity : 50 to 450 tph pressure : upto 125 kgcm2 sh temperature : upto 540oc application : power generation

fluidized bed boiler

Get Price Quote

fluidized bed boiler, Heat Recovery Boiler, Oil Boiler, fire tube boilers

Primax Fluidised Bed Boiler

Get Price Quote

Primax Fluidised Bed Boiler, Steam Boilers, baby boilers, Smoke Tube Boiler

fluidized bed boilers

Get Price Quote

fluidized bed boilers, Bricks, Bottom Pouring Sets, Refractory Lining

Atmospheric Fluidized Bed Boilers

Get Price Quote

Atmospheric Fluidized Bed Boilers, Single Drum Water Tube Boilers

Atmospheric Circulating Fluidized Bed Combustion Boilers CF

Get Price Quote

Atmospheric Circulating Fluidized Bed Combustion Boilers CF

fluidized bed boiler

Get Price Quote

fluidized bed boiler, Popcorn Machine, Water Cooler

fluidized bed boiler

Get Price Quote

fluidized bed boiler, Agro Waste Boilers, Semi automatic boiler

Atmospheric Fluidized Bed Combustion Boilers

Get Price Quote

Atmospheric Fluidized Bed Combustion Boilers

Atmospheric Fluidized Bed Combustion Boiler

Get Price Quote

Atmospheric Fluidized Bed Combustion Boiler

Atmospheric Fluidised Bed Combustion Boiler

Get Price Quote

Atmospheric Fluidised Bed Combustion Boiler, Boilers