Fly Ash Brick Plant

4,500,000 Per Set

1 Set (MOQ)

Fully Automatic Fly Ash Brick Plant

1,540,000 Per Set

1 Set (MOQ)

Best Deals from Fly Ash Brick Plant

Fully Automatic Fly Ash Brick Making Plant

800,000 - 850,000 Per piece

1 piece (MOQ)

RTP 09 CP Fly Ash Bricks Making Plants

1,700,000 Per Piece

fly ash brick making plant

1,650,000 Per Set

automatic fly ash brick making plant

4,050,000 Per Set

1 Set (MOQ)

Fly Ash Bricks Batching Plant

Get Price Quote

1 Unit (MOQ)

Three Bin Automatic Batching Plant for Fly Ash Brick Making Machine

14 Per Piece

1 Piece (MOQ)

Fly Ash Brick Plant

Get Price Quote

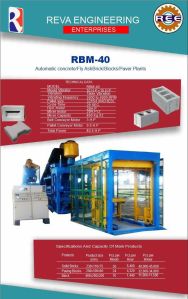

We are offering fly ash brick plant special features : reva has produced the most versatile plants for the manufacture of fly-ash bricks/ pavers/ tiles/ blocks made out of fly ash as the main constituent in combination with sand, lime and gypsum. Bricks can also be produced out of fly-ash and cement mix or sand lime or sand cement i.e. The same machinery can be employed for making concrete bricks/soil bricks. the process consists of mixing and grinding the materials in the pan mixer. With the addition of batching equipment, the material can be mixed with, in the required proportions by weight, to have uniform quality most economically. The mixed and ground materials are conveyed on the belt conveyor to the reva brick making machine from where the hydraulically compressed bricks are continuously produced and taken to the curing site on pallets by the pallet trucks/conveyors, where, bricks are cured by water spray or steam cured for early strength. the main machines of the system are pan mixer, belt conveyor, brick machine, and pallet trucks along with the wooden pallets. pan mixer (model 500 kg) reva pan mixer is specially designed for thorough mixing of the fly ash ingredients with the grinding of the lime, gypsum and other coarse and granular materials in the powder form.power is transmitted from the electric motor to the pan mixer through the heavy duty worm reduction gear box provided below the pan mixer.hard wearing liner plates are bolted and can be changed when required.easy bottom unloading mechanism.heavy cast iron rollers revolving on bearings with metal seals are provided to grind the material to the desired shape and size.changeable mixing and discharge blades are of special alloy steel with hard faced tips.the pan mixer has a capacity of 500 kgs. Per batch and powered by 15 h.p., 3 electric motor. belt conveyor : reva belt conveyor is made of sturdy steel frame.power is transmitted from the 3 h.p electric motor to the reduction box and to the conveyor roller.the fly ash mix can be regulated according to the speed of the brick making machine.conveyor belt is made of nylon belting with rubber top.frictionless idlers are provided with seals on both sides to prevent any ingress of fly-ash and dust, etc. Going in side the bearings to the idlers. hopper : a collecting hopper is provided below the discharge gate of the pan mixer in order to collect and stock the mixed material from the pan mixer and discharge the required quantity on to the belt conveyor. It is bolted on the belt conveyor's frame. reva brick machine : reba brick machine is hydraulically operated, automatic, plc controlled, self diagnosing type, having digital display.computer connection can be fitted if required.the machine develops approx. 35 tones of hydraulic force on the bricks for the required time to make the bricks uniform.the compressive force is adjustable as per requirements the machine is robustly constructed, steel structured, heavy duty, designed for taking up all types of heavy loads, due to variations in raw materials. various types and sizes of moulds can be fitted with a maximum size 250 by 250 by 100 mm. different types of monograms, frogs can be made on the bricks. the machine gives a very high production. The output is adjustable maybe from 10,000-12000 bricks per j hr. Shift or more, at a very economical cost.for continuous running of the machine, the hydraulic oil cooling arrangement is provided on the machine. the machine is powered by 15 h.p., three phase electric motor and is fitted with hydraulic pump, hydraulic motor, hydraulic cylinders direction control valves, etc. the table rotation is hydraulic, 3 stationed plc controlled with manual and auto operations. pallet trucks : specially designed to handle the bricks with pallets for effortless and easy transportation of flyash bricks with reduced labour provided with 3 nos. Pneumatic tyre wheels.hydraulic hand operated arrangement for lifting or lowering the pallets. auto batching system : radial scraper or storage hopper weigh bin with pneumatic operated gates for fly-ash and sand loading, hydraulic / electrical rotation.water batching system with feeding pump with digital display..

automatic fly ash brick plant

1,050,000 Per Piece

1 Piece (MOQ)

Neptune Hey 1500 Fly Ash Brick Plant

1,900,000 Per Set

1 Set (MOQ)

fly ash bricks making semi automatic plant

450,000 Per Long Ton

Manual Fly Ash Brick Making Plant

Get Price Quote

We take care of all the raw materials used in the product manufacturing and designing. The inputs (raw material) used are quality certified and are remarkable for the production. With the leading market standards and customers' demands, we have developed a system that allows the clients to pay in online and offline as per their preferences.

Fully Automatic Fly Ash Brick Plant

Get Price Quote

We are instrumental in bringing forth a comprehensive range of Fully Automatic Fly Ash Brick Plant, which is precisely engineered to suit the specific requirements set by the industry. Our Fully Automatic FlyAsh Brick Plant is manufactured using high grade components making them highly durable in nature. SpecificationsBased on Hydraulic Powder compacting technologyHas fully automatic programmable functions Use of imported PLC SystemHigh output speedAdoption Of Following SystemsMechanical system & HydraulicsElectronicsInstrumentation & controls Productivity ModelFEBP - 03Brick Size230x110x75 mm190x90x90 mmNo of Bricks per stroke67No of Stroke55No of Bricks/min3035No of Bricks per Hr18002100No of Bricks /Shift ( 8 Hrs)1224014280No of Bricks/Day240002800 Note No of Bricks /Shift ( 8 Hrs) : PLF of 85%No of Bricks/Day : 2 Shifts per day Production Process of Automatic Hydraulic Brick Press Plant Raw Material feedingManual feeding/Volumetric ControlMixingBatch type intensive rapid mixing with manual water feeding.Brick ProductionPowder compacting technology with PLC controlled system to give sufficient pressure for inter-molecules bondingGreen Production HandlingManually on PalletsGreen Product CuringManual Curing System By Sprinkling Water jets Bricks Specifications ParticularsValueUnitRemarks

automatic fly ash brick plant

Get Price Quote

Heavy structure body with four nos. of shaft to guide the Ram Punch of Mould, Electric Panel (With Mitsubishi PLC,). Production Capacity 40,000 to 45,000 Bricks/Shift. 7.5x2 H.P. Mould Vibrator, [Automatic material feeder and Pallet Feeder, Hydraulic operated, controlled by PLC. Pan Mixer having capacity of 850 Kgs. X 2 quality Worm Reduction Gear Box Elecon/Roto-Reva make powered by 25 H.P./ Electric Motor With Star-Delta starter. Belt Conveyor for loading and unloading the material of the Pan Mixer of app. 31 ft. and powered by 3 H.P. Electric with quality gear box with starter. With Storage Bin Finished Bricks Conveying Conveyor 12 Feet Approx, Powered by 1H.P. Geared Motor. 4 Nos. Pallet Trolleys. Auto Batching System of 3 Bins for Raw Material. Weighing of the Raw Material on the Belt Conveyor with help of the Load Cells and Automatic Batch control System and Computer Printing Facility and one week data storage. Automatic Discharge of the Raw Material. Weighing conveyor controlled by 5 H.P. Geared Motor and ½ H.P. Chute vibrator on the Bins of Aggregate. Automatic Stacker for Lifting the Pallets with Bricks. Powered by 01+02 H.P. Electric Motor, Controlled by Variable Frequency Drive, Controlled by Mitsubishi PLC. 1. Screw Conveyor of 31 Feet, powered by 5 H.P. geared motor and Accessories. 2. Cement weigh Hopper with butterfly valve discharge. 3. Cement storage capacity 1000 kgs.

Fly Ash Plant

Get Price Quote

We are manufacturing fly ash plant. Main equipment drying -if require material handling storing classification packing.

Aaditya Fly Ash Brick Plant

7 - 8 Per piece

1500 piece (MOQ)

Fully Automatic Fly Ash Brick Making Plant

1,850,000 Per Piece

1 Piece(s) (MOQ)

This Is Our 10 Bricks Fully Automatic Fly Ash Bricks Machine/ Production Capacity - 16,000-19,000 Bricks Per Shift, 8Hrs 150Ton Pressure 33Hp Power Req. 6FtPan Mixture - 2 Nos 26Ft. Conveyor Belt - 1 Nos Material Trolley - 2 Nos 400Ltr. Oil With PLC Panel & Hydraulic Power Pack Total Area - 15,000Sq. Ft. Machine Shade Requirement - 1,500Sq.Ft. With 16Ft. Height

Fly Ash Bricks Making Plants

Get Price Quote

1 Pair (MOQ)

Supported by sound infrastructure and a team of highly experienced professionals, we are able to manufacture, supply and export automatic bricks making machine. Owing to their automatic operations, these machines are widely used for making bricks requiring less human efforts. Our highly dedicated professionals manufacture these machines using qualitative metals and other components so as to ensure their durability and robust construction. Offered automatic bricks making machine is appreciated by our clients for its high efficiency, low maintenance, prolonged functional life and least power consumption.

Fly Ash Brick Plant

Get Price Quote

Our company is a renowned manufacturer and supplier of fly ash bricks making machine. Our range of fly ash bricks making machine includes semi automatic fly ash bricks making machine and fully automatic fly ash bricks making machine. The residues that are generated by the combustion of coal in the thermal power plants are called fly ash. Fly ash can cause serious health hazards, if left under dry conditions in the ash ponds. Fly ash reacts with lime in the presence of moisture at ordinary temperature. After continuous r&d and testing, it was found out that through the reaction of fly ash with lime, calcium silicate hydrates are formed. The compound formed has cementitious properties and is high in strength. Clients can avail highly efficient and reliable semi automatic fly ash bricks making machine from us in various specifications at competitive prices.