forced circulation evaporator

230,000 Per Piece

1 Piece (MOQ)

forced circulation evaporator

2 - 8 Per Piece

In Forced Circulation Evaporators water is distributed in tubes like a fine film layer on surface of tubes. Due to less wetting in surface and scaling, fouling materials will form a layer of insoluble scale that reduce its evaporation capacity. During evaporation, scaling materials such as calcium, magnesium & silica salts are forms quick and insoluble layer of scales. This will reduce heat transfer and affect system performance. For that, we recommended forced circulation system.In that design, feed is flow inside of tube with tube filled condition and with high velocity and pressure. Due to velocity and pressure, boiling on tube surface is reduced. Pressure inside of system is maintained to avoid boiling inside of tube by vapour head pressure. Further velocity in forced circulation keeps surface on wiping and cleaning. This will not allow developing scales on surface by force of feed water.Feed vapour is separated in vapour separator. Further, with forced circulation system, we can run system with semi slurry conditions with very high concentrations There is no boiling on calandria and heating only happened in calandria. Boiling happened in vapour separator and concentration without scaling is achieved. Further high concentration water and semi slurry water is processed.This will help to separate salt by crystallizer, pusher centrifuge or dryer. By forced circulation system, we can achieve zero discharge system effectively. We installed many forced circulation system up to 80kld capacity. This system is used to high fouling, scaling water, salt separation by crystallizer and pusher centrifuge.

Best Deals from Forced Circulation Evaporator

Forced Circulation Evaporators

Get Price Quote

Advantage : Ideal for high crystallizing and high viscosity solutions & Slurries. Single or multiple effect evaporation High operational flexibilities, heat transfer co-efficient, vapours liquid separation. Low temperature rise operation. Minimized fouling due to high velocities & static head. High turn down ration.

Forced Circulation Evaporators

Get Price Quote

forced circulation evaporator

Get Price Quote

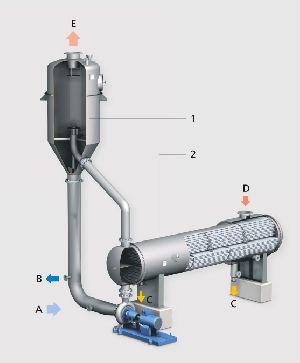

Working in assistance with a brilliant inventory management system and capacious storehouse has enabled us to entertain urgent and massive requirements of the customers. The organization is indulged in offering secured payment procedure including both online and offline methods. To maintain more clarity of the transaction, we offer an invoice as well. Synchronizing with the advancements taking place in the industry, we are engaged in providing Forced Circulation Evaporator. Features : Low utility consumption Solvent recovery Compact Design Easy operations Durable nature Efficiency Forced/Natural Circulation Evaporation is used when boiling of base liquids is undesired. Details : Forced circulation evaporators are used if boiling of the product on the heating surfaces is to be avoided due to the fouling characteristics of the product, or to avoid crystallization. The flow velocity in the tubes must be high, and high-capacity pumps are required. The circulating liquid is heated when it flows through the heat exchanger and then partially evaporated when the pressure is reduced in the separator, cooling the liquid to the boiling temperature corresponding to this pressure. The liquid is typically heated only a few degrees for each pass through the heat exchanger, which means the recirculation flow rate has to be high. This type of evaporator is also used in crystallizing applications because no evaporation, and therefore no concentration increase, takes place on the heat transfer surface. Evaporation occurs as the liquid is flash evaporated in the separator/flash vessel. In crystallizer applications this is then where the crystals form, and special separator designs are used to separate crystals from the recirculated crystal slurry. The heat exchanger (in evaporator parlance sometimes called the "calandria") can be arranged either horizontally or vertically depending on the specific requirements in each case. Advantages : Circulation evaporators are fairly compact and are easy to clean and operate. They can also be easily adapted according to the product that needs to be obtained. They have a high heat transfer coefficient as well as a high circulation flow,which both work to increase the efficiency of the evaporator.

forced circulation evaporator

Get Price Quote

forced circulation systems

Get Price Quote

Forced circulation Evaporator is used where boiling of the product is steering clear due to its bad foul characteristics. When the mixture flows through the heat exchanger it get partially vaporized because of the decrease in pressure. In this process powerful circulation pump forces the liquid through the help of tubes. The heat is picked by the shell side which carries steam. The height of the liquid is designed in a way thio stay away from the nucleate boiling inside the evaporator tube bundle. This type of equipment can be mounted vertically or horizontally according to the client’s need.

forced circulation evaporator

200,000 Per Piece

Features Due to less residence time and system under vacuum product quality remains good Design for low temperature difference hence fouling should be avoiding Simple in operation Suitable for heat sensitive products Liquid distributor is design in such that way that equally distribution of liquid inside tube

forced circulation evaporator

Get Price Quote

1 Piece(s) (MOQ)

Forced Circulation Evaporator that we offer is extensively used in such cases where the boiling of the product is steering clear due to its bad foul characteristics. When the mixture flows through the heat exchanger it gets partially vaporized because of the decrease in the pressure. In this process, powerful circulation pump forces the liquid through the help of the tubes. The heat is picked by the shell side which carries steam. The height of the liquid is designed in a way to stay away from the nucleate boiling that is present inside the evaporator tube bundle. The Forced Circulation Evaporator can be mounted horizontally or vertically as per requirement. Additionally, it can also strengthen the solid substances into the liquid before drying. It ensures a moisture-free process. Further, the efficiency of forced circulation evaporators is entirely dependent on the heat temperature of the steam and the solution. Our Forced Circulation Evaporator is widely applied in waste water concentration, concentration of inorganic as well as organic salt solutions, evaporative crystallization, etc. Meticulous features of Forced Circulation Evaporator : Ideal For Crystallization Concentrated Values Steam Economy Multiple Arrangements For High Performance High Capacity Minimum Consumption Of Energy Applications Of Forced Circulation Evaporator Waste Water Concentration Concentration Of Inorganic As Well As Organic Salt Solutions Evaporative Crystallization Our manufactured products are made up of finest quality of raw materials due to which it ensures durability in the product nature. There are mainly three factors in our designed products which are the main keys of our success and these are quality designs, competitive price and timely delivery. We Have Cover Following Markets : USA : New-Mexico, New-Jersey, Alaska-Nevada, South-Dakota, Montana, Florida, Texas, etc. Middle East : Yemen, Oman, Israel, Cyprus, Egypt, Arabia, Kuwait, Jordan, Syria, Saudi, etc. Europe : Finland, Croatia, Sweden, Malta, Andorra, Albania, Austria, Poland, Monaco, Italy, etc. Others : Maldives, China, Myanmar, Nepal, Bhutan, Pakistan, Bangladesh, etc Indian Areas : Himachal-Pradesh, Punjab, West-Bengal, Mumbai, Rajasthan, Andhra-Pradesh, Delhi, Gujarat, Bihar, Karnataka, Assam, Haryana, Madhya-Pradesh, Orissa, etc.

forced circulation evaporator

Get Price Quote

In Forced Circulation Evaporator the liquid is pumped in the tubes with high velocity. As the liquid enters the separator where the absolute pressure is slightly less than in the tube bundle, the liquid flashes to form a vapor. It is suitable for use with materials that tend to foul the heat transfer surfaces and where crystallization can occur in the evaporator in the vapor separator.

Forced Circulation Evaporators

100,000 Per Piece

1 Piece(s) (MOQ)

Custom manufacturer of forced circulation evaporators. Features include high flow velocity tubes, high-capacity pumps & heat exchangers. Forced circulation evaporator have high recirculation flow rate. Forced circulation evaporators are used if boiling of the product on the heating surfaces is to be avoided due to the fouling characteristics of the product. Forced circulation evaporators are also used in crystallizing applications because no evaporation & therefore no concentration increase, takes place on the heat transfer surface.

forced circulation evaporator

Get Price Quote

Circulation evaporators are a type of evaporating unit designed to separate mixtures unable to be evaporated by a conventional evaporating unit. Circulation evaporation incorporates the use of both heat exchangers and flash separation units in conjunction with circulation of the solvent in order to remove liquid mixtures without conventional boiling. These type of evaporators some mechanical device are fitted to circulate the contents heating in it. For example an evaporating pan in which the materials is agitated by a stirring rod or by a mechanical propeller. The liquid is circulated by means of a pump and as it is under pressure in the tubes the boiling point is raised and no boling take places. And it enters the body of the evaporator.

forced circulation evaporator

500,000 Per Piece

forced circulation evaporator

Get Price Quote

The Forced Circulation Evaporator has been developed over the past 20 years and we have specialized in treating difficult fluid wastes like oil emulsions, dissolved salts, heavy metals, radio-active and other hazardous chemicals, suspended solids etc. The main applications are concentration andor recovery of oil emulsions, metal salts, leachate, organic solvents and other difficult waste water.

Forced Circulation Evaporators

Get Price Quote

The forced circulation evaporators serves as ideal evaporators for the condition where liquids possess the tendency to crystallize and scale when concentrated. The circulation is maintained by pumping the liquid with the help of heating element irrespective of heating and evaporation rate. Features High Power Consumption High rate of heat transfer Ease of cleaning and a wide range of application. Relative freedom from salting, scaling, and fouling Economical and less utility consumption

forced circulation evaporator

Get Price Quote

Forced Circulation Evaporator for concentration of high viscosity material and products with higher solids. This is also used as evaporative crystallizer. To achieve desired concentration Falling Film Evaporator followed by Forced Circulation Evaporator is used to minimize the operating cost. In this type of evaporator, the liquid is pumped through tube side of Calandria at high velocity avoiding precipitation and fouling;the liquid is then passed through vapor separator for separation of vapor. Concentrated liquid is continuously discharged from bottom of the vapor separator with pump.

forced circulation evaporator

Get Price Quote

Forced Circulation Evaporatoris the most common type of evaporation system and widely present in process industry for different application. In this type of evaporator liquid is recirculated by a pump through the heat exchanger at high velocity.Forced circulation evaporators are used if boiling of the product on the heating surfaces is to be avoided due to the fouling characteristics of the product. The evaporator system is used for procession liquor which are susceptible to scaling or crystallizing.

forced circulation evaporator

Get Price Quote

In Forced Circulation Evaporator the liquid is pumped through the tubes with high velocity. As the liquid enters the separator where the absolute pressure is slightly less than in the tube bundle, the liquid flashes to form a vapor.It is suitable for use with materials which tend to foul the heat transfer surfaces and where crystallization can occur in the evaporator.

Forced Circulation Evaporators

Get Price Quote

forced circulation evaporator

Get Price Quote