Nut Forging Die

25,000 Per Piece

10 Piece (MOQ)

Trimming Dies For Hex Flange & Collar

Get Price Quote

30 Piece (MOQ)

The company is located in Rohtak(India) and caters to the diverse requirements of the buyers. We follow strict warehousing rules and thus we keep the extensive range of products safe in our well-structured warehouse, which is supervised by our team of experts.

Best Deals from Forging Dies

Forging Dies

Get Price Quote

1 Piece (MOQ)

We are renowned Manufacturer & Supplier of Forging Dies which are widely demanded in the industry. Our products are capable of meeting the difficult requirements of the industries. These are designed for efficient performance and have the most robust built. We bring forth the most qualitative Forging Dies in a very reasonable price range. These are delivered to the clients well within time. Features Strong Durable Superior quality High performance

Forging Dies

Get Price Quote

The Forging Dies, which we supply, are reckoned for their make and quality. Having a wide network, we work on all Payment Terms as per the suitability of our patrons. Our payment procedures are reliable and legal. We do not impose hidden charges. We can be contacted for customized packaging solutions. Besides the standard packs, we can sort items in desired quantity and pack them accordingly. Our packaging is premium.

Hot Forging Dies

Get Price Quote

Being a client centric organization, we are involved in offering a wide range of Hot Forging Dies. These Hot Forging Dies are precisely designed and developed using optimum quality components and following international industrial standards. With the availability in various standard sizes, dimensions and shapes, these dies are widely used for various industrial applications.

Graphite Forging Die

Get Price Quote

We are among the leading manufacturers, suppliers and exporters of Graphite Dies. Manufactured as per the industry set standards, these dies are used for the continuous casting of different metals and alloys. In order to ensure a defect free range,

cold forging dies

2,500 - 16,500 Per Piece

We can supply cold forging dies for fasteners industry. Carbide heading. Dies, Carbide trap Dies, Carbide extrusion Dies, Carbide Long shank forming Dies, Carbide Nut forming Dies, Carbide 2nd stn. Hex. Dies etc. Good quality, Cheap price.

Forging Dies

Get Price Quote

With our dedication towards quality, we have successfully established ourselves as a Manufacturer and Supplier of Forging Dies. Forging Dies are used for forging process, typically hot forged, a metal forming process that involves the metal being heated to a specified temperature and then modified. Some steel alloys require a modification of the hot forging process to ensure grain strength, resistance to corrosion, and limited oxidation. Due to a high level of corrosion resistance, stainless steel Forging Dies are used to create many components.

Valve Forging TC Dies

25,000 - 250,000 Per piece

1 Piece (MOQ)

forging die

Get Price Quote

Our entire range is value for money, as it is quality guaranteed, sold after a string of quality control tests, and is relied on by many. We have adopted several methods for making safe and hassle-free payments. The customers get both offline and online options to make payment to us.

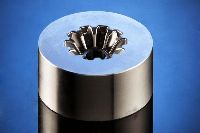

cold forging die

Get Price Quote

Bevel Gear Dies are made out of high hardened material with 60 HRC. The ability to forge these metals and the amount of possible deformation depends greatly on the chemical composition and annealed properties of grade. Properties such as hardness and ductility are critical properties in determining the formability of a metal. It is important to know that the mechanical properties of materials are greatly improved after cold forming. Sometimes this improvement is so great that grades which would have been considered unsuitable if machined, warm forged, or hot forged, could have suitable mechanical properties for the application after cold forming. The improvement in mechanical properties of a grade depends partly on the amount and type of deformation taking place. Portions of the forging that see little work will not see as great improvement as the locals of greater deformation.

Forging Dies

Get Price Quote

Hot Forging Dies

Get Price Quote

We are offering hot forging dies in the industry. Our resistant cast hot forging dies are noted for effective performance even in high temperature condition. These hot forging dies do not deform in any condition. In addition to this we are acknowledged as one of the dominant hot forging dies mold suppliers and a prominent exporter of the same. attributes abrasion resistanttemperature resistantdurable affordable rates used in engine valve making industry

Forging Dies

Get Price Quote

We are a prominent Manufacturer and Supplier of the best quality Forging Dies. We can manufacture all types of Forging Dies using the advanced technology. Forging Dies are tested on various parameters before the final dispatch. Besides, we can handle the bulk orders of Forging Dies as per the requirement of the clients. Highlights : High strength Expert design Best quality Affordable price

Forging Dies

Get Price Quote

When buyers select a process and supplier for the production of an important metal part, they face an enormous array of possible alternatives. A great many metalworking processes are now available, each offering a unique set of capabilities, costs and advantages. The forging process is ideally suited to many part applications, however some buyers may be unaware of the exclusive benefits available only from this ancient form of metal forming. In fact, forging is often the optimum process, in terms of both part quality and cost-efficiency-especially for applications that require maximum part strength, special sizes or critical performance specifications.

Forging Dies

50,000 Per Piece

1 Piece(s) (MOQ)

Since our inception we have developed more than 800 complex assemblies which is combination of Press Tools, Moulds, Welding fixtures and Relation guages. We provide solutions for complex Dies, molds and fixtures. Our team of experts backed with complete Tool Room setup and latest technologies ensures perfect trials and timely deliveries. Our solutions in this domain include 1. Press Tools 2. Forgings dies 3. Pneumatic welding fixtures 4. Hydraulic fixtures 5. Relation guages

Carbide Cold Forging Dies

3,000 Per Piece

Valve Forging Dies

Get Price Quote

Extensive market research and survey is conducted by us to ensure that an exclusive range of Draw Dies are offered by us. Production process is carried under the strict quality control of our quality monitoring experts, who have years of experience. Utilization of sophisticated designing patterns enables us to design our range as per set industrial trends. We ensure safe dispatch of our Draw Dies at our customer's premises.

Cold Forging Cutting Die

1,500 Per Piece

10 Piece (MOQ)

cold forging die

Get Price Quote

The use of finite element method increasingly as tool in metal forming industry result in cost reduction, time saving and improvement in product quality. The simulation software in the cold forging industry show material flow, capture the defects and allow to determine the process parameters such as pres forces, die stresses, predict the tool life and fracture and calculate residual stresses. The p

Forging Dies

Get Price Quote

Cold Forging Carbide Dies

Get Price Quote

We are a reputed brand in the industry that is known for presenting an excellent range of Cold Forging Carbide Dies in India. Owing to their wide use, our Cold Forging Carbide Dies are widely demanded. We make use of top quality material for manufacturing Cold Forging Carbide Dies. We can make available Cold Forging Carbide Dies in different specifications, defined by the customers. We offer Cold Forging Carbide Dies at feasible prices.

Precision Forging Dies

Get Price Quote

We are among the most preferred choices of our clients in offering a comprehensive range of Forging Dies. Our offered range is well tested by our professionals on various defined quality parameters in order to maintain its high quality and efficient work performance. Our client’s can avail this offered range at pocket friendly rates. Features: • High strength • Accurate dimension • Sturdiness • Timely services • Customized services

cold forging die

Get Price Quote

Our clients can avail from us, a wide range of the best quality T C Cold Heading Machine which is widely used in various industrial sectors. Known for high-volume production, these are fabricated using the finest quality raw material and latest technology. The offered range is widely praised among our clients for its maintenance free, longer functional life, corrosion resistance, sturdy construction and hassle free operation features. These are stringently tested on various parameters by our quality controllers for delivering flawless range at our clients’ end.

Forging Die & Punch

Get Price Quote

The company has come up as a major Manufacturer & Supplier of Forging Die & Punch. The Forging Die & Punch is widely used for forging and is available in diameters of 40-800 mm. the company uses the best grade raw materials like case harden steel, alloy steel, cast steel and die steel for the production of the Forging Die & Punch. Applications Sugar Mill Rolling MillHot MillOil Industry

Forging Dies

Get Price Quote

1 Piece(s) (MOQ)

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer or a die. Forging is often classified according to the temperature at which it is performed: cold forging, warm forging, or hot forging. For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons. Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing to achieve a finished part.

Hot Forging Dies

Get Price Quote

We Offer Hot forging dies are exposed to severe mechanical and thermal cyclic loading. This causes hot wear, cracks and plastic deformation in the die. To prevent this, use materials with good hot strength and ductility/toughness. Uddeholm Orvar Superior or Bohler W303 Isodisc are suitable in most standard hot forging applications. When higher toughness is demanded, use Uddeholm Dievar or Bohler W400 VMR.

Forging Dies

Get Price Quote

Our organization is endowed by a massive circulation system that allows us to reach purchasers wherever and distribute orders on schedule. In order to keep a strict check on the quality of the products, we maintain a streamlined quality management process.

Forging Dies

Get Price Quote

Forging Dies, CNC Machined Component, Forged Components, Die Casting

Forging Dies

Get Price Quote

Forging Dies, blow molding, Rubber Molds, press dies