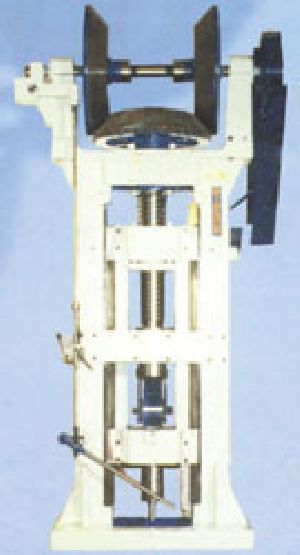

Up Stroke Forging Screw Press

756,000 Per piece

1 Piece (MOQ)

Hot & Cold Forging Press Machine

Get Price Quote

1 piece (MOQ)

Best Deals from Forging Press

Forging Press

Get Price Quote

Located in Raipur(India), ours is the name trusted for meeting the exact requirements of the clients. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements systems.

Forging Press

Get Price Quote

Hot Forging Press Make: Voronezh (Russian) Model: KB8542 YOM: 1977 Specifications: Ton 1600 Slide stroke: 300 mm Slide stroke length at maximum force � 0,16 mm Distance adjustment between table and slider � 10 mm Slide stroke number in 1 min � 75 Length of a rod � 920 mm The closed height (the least distance between a table and a slider in his bottom position) � 660 mm Table overall dimensions � 940x1200 mm Table height above floor level � 450 mm Slide overall dimensions � 860x910 mm The size of lateral windows: -Height � 560 mm -Width � 600 mm Main motor � 110 kW Press overall dimensions: -Length � 5060 mm -Width � 3940 mm -Height above floor level � 5125 mm Press weight � 120 ton Location: Russia Condition: Working

Hydraulic Forging Press

Get Price Quote

10 Units (MOQ)

forging screw press

Get Price Quote

These Friction Screw Presses are preferred for Hot Forming (Forging) and Cold Coining, Stamping, Embossing, Sizing non-ferrous metal.The press body is of steel welded construction, one piece box type design, The screw is made of high quality alloy steel and is heat treated to give hardness and elasticity.

forging screw press

Get Price Quote

Forging presses & Friction Screw Presses which are the essence of Technical ability and skill of Engineers. We are manufacturing all kind of presses i.e. Forging Presses, Friction Screw Presses and Power Presses. Needless to add the beauty of our designs are to incorporate maximum possible facilities to their users without incurring exorbitant investments.

Closed Die Hot Forging Press

Get Price Quote

The Closed Die Hot Forging Press is reliable, smooth, and easy to maintain and it is widely used on bearings, vehicles, and valves. Being a major Supplier of Closed Die Hot Forging Press, NHI China offer DRF, DRC and DRX series, which are lightweight and rigid with higher guiding precision. The Closed Die Hot Forging Press can be used in the industry and military as well as aviation areas.

Forging Press

150,000 - 350,000 Per Piece

1 Piece (MOQ)

forging screw press

Get Price Quote

HP Singh Machinery Pvt. LTD is a renowned manufacturer, supplier and exporter of Friction screw presses. The Screw is made of high quality alloy Steel and is heat treated to have great hardness at the same time great elasticity. Commonly used in hot forming (forging) and cold coining, stamping, embossing, sizing non-ferrous metal. We have been providing quality machines to our clients at the most reasonable prices.

forging screw press

Get Price Quote

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging.Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top. On machines employing the Vincent principle, the screw nut is positioned in the top cross head of a frame type ram. Thus Ram is moved upwards in axial direction by rotation of longitudinally fixed screw.

Hydraulic Forging Press

100,000 Per Piece

1 Piece(s) (MOQ)

6000 tons Hot Forging presses

Get Price Quote

MI7432 Capacity: 6000 ton, Bed size: 1700 x1550 mm Ram stroke: 460 mm, Strokes per minute: 36 spm, Shut height: 1150 mm, Die seat (R-L x F-B): 800 x 2050 mm, Ram face (R-l x F-B): 1700 x 1550 mm, Tie road diameter: 510 mm. Width between the columns: 1850 mm, Floor space (R-L x F-B c HAF); 6400 x5700 x 7500 mm, press net weight; 550000 Kg (550 ton) Price: USD 9 Million EXW India

150 ton Hydraulic Metal Forging Press

750,000 - 780,000 Per Piece

1 Piece (MOQ)

FRICTION SCREW FORGING PRESSES

Get Price Quote

FEATURES Hot Forgings. Investment costs low & Cost for foundations are minimal. The forging Dies have a long life. Costs of development, manufacturer & replacement of the dies are low. Great forging accuracy is achieved because of the free stroke. Additional energy can be applied to the same die impression by making several blows. The heat contact time considerably less than it with crank type forging presses & knuckle joint presses. Cost of repairs after years of hard usage is low. Only skilled labor should be employed for its usage. Our Friction Screw Presses are heavy duty fabricated construction and are suitable for endless variety of Non-Ferrous Stamping, Forgings and Piercing operations depending on the tooling employed on it. Even these are utilized for planership and finishing of articles which has been produced on Power Presses or by castings. These presses are being manufactured from 30 to 500 Tonnes Capacity. Their design beauty is that they can give 1/2" stroke with full press force. Moreover any type of ejection arrangement can be supplied along with the press against specific requirement.

Hot Forging Press

Get Price Quote

We manufacture and supply high quality Hydraulic Hot Press . This Hydraulic Hot Press is used to formulate plywood boards, flush door, PC boards, FRP composite laminates, coir mattresses and rubber moldings according to user’s requirements. Our Hydraulic Hot Press is known for its superior quality and high performance among the clients. Highlighting Features High performance Sturdy construction Longer working life.

Hot Forging Press

9,000,000 Per unit

1 Unit (MOQ)

Forging Screw Press (Up Stroke)

Get Price Quote

These screw presses are specially designed to make bolt head of any kinds of nuts, rivets, motor parts, axle half shaft, engine valve and nonferrous forgings. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction i.e. from bottom towards top. On machines employing the vincent principle The screw nut is positioned in the top cross head of a frame type ram. Thus ram being moved upwards in exial direction by rotation of longitudinally fixed screw. The bottom die of the Forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frame but are sustained by the ram. Ejector is provided at the lower part of the ram.

Hot Forging Press

Get Price Quote

ForgePro ensures right quality in all aspects and supply on time. We are following best world class practices to ensure continual improvement on process and product quality. We have complete in-plant quality control and an inspection department to maintain our high standards of precision and accuracy of forgings. A high level of vertical integration and world class quality systems ensure total control on quality of products supplied. Control of the conformity with the requirements is conducted based on constant measurements. Quality can be assured only by motivating people to improve the quality of products. Assuring quality is the task of all employees, so all must participate in order to achieve the set objectives. Our goal is an annual decrease of rejection%, thus consequently increasing quality towards "0 PPM strategy"

Forging Press

Get Price Quote

forging screw presses

Get Price Quote

Our FORGING SCREW PRESSES allow the production of large and small batches of all kinds of threads that can be cold formed, in the most economical way. The normal basic data stated in the table for each machine type are not limiting values. Practical tests in the areas of manufacturing techniques and material behaviour extend performance limits of our machines further and further. Our developments are being determined by and over increasing and move accurate knowledge which enable us to conceive tailor made designs for SPECIALS APPLICATIONS, MATERIAL SPECIALITIES, SPECIFIC DIMENSIONS & DIE-SHAPES.

Forging Press

Get Price Quote

We are offering forging press. We manufacture forging press from h framec frame column structure as per customer demand.

Hydraulic Forging Press

Get Price Quote

We are one of the leading manufacturers and suppliers of one of the primary equipment of the industrial sector namely Full Hydraulic Forging Press.This machine uses hydraulic force for forging press activity. The main property of this equipment is that it generates huge amount of mechanical energy, which is of great help in the industrial sector. Features: Available in different configurations Rigid construction Fully and semi- automatic

Straightening Forgings Open Throat Press

Get Price Quote

OPEN THROAT PRESS With Straightening Forgings Presses from 63 KN. to 2000 KN. capacity and straightening attachment for bar length 100 mm to 5000 mm can be supplied. Efficient hydraulic system for hydraulic power generationusing latest power generation using latest logic control/proportional values we manufacture presses of manually operated type,electrical push button operated type , PLC/PC based programmable type. Features 0–100 Hz cycling frequency Hydraulic lifts and clamps 50/100/250/500 kN force rating actuators +/-100 mm stroke actuators Adaptable to wide range of fixtures & grips Actuator on fixed bottom crosshead Electronically servo-controlled variable flow, variable pressure, low noise, energy efficient pump 5+ kHz 32-bit digital closed loop control 24-bit data acquisition Applications Fatigue crack propagation Fracture mechanics Room temperature tests High temperature tests Testing in corrosive environment Tension/compression Low/High cycle fatigue (LCF/HCF)

Forging Press

Get Price Quote

Long life,High performance , Low operating , Cost Untitled Document,Capacity;Ton 400 630 800 1000 1600

cold forging press

Get Price Quote

Kalyani Forge has been manufacturing warm and cold forged components over a decade. The primary advantage of cold forging is the material saving achieved through precise shape, which requires little finishing with no shrinkage and scaling. We can thus achieve better control on the process and quality of products.

Friction Screw Forging Press

Get Price Quote

hydraulic cold forging press

1,150,000 Per Piece

forging screw press

Get Price Quote

Technical Specification The famous name in Down-Stroke Friction Screw Press,Up-stroke Forging Screw Presses, New Model Down-Stroke Forging Screw Presses (Steel Body) and Power Presses.1. These are manufactured under strict supervision of qualified technicians.2. These are most precise presses, smooth running, durable, strong in construction, accurately finished and very easy in installations.3. H.S.Birdi Industries minimize the cost of production, famous for trouble free performance and are fully guaranteed for service.Terms1. Delivery Ex – Factory Ludhiana.2. Packing Forwarding Extra.3. Sale Tax Charged Extra where applicable.4. Rates are valid for 10 days.5. Insurance will be charged extra.6. 30% Advance with confirmed order and balance against delivery of dispatch.7. All rates are without electrical.8. Subject to Ludhiana Jurisdiction only.Application:1. Forged gear, Bolts, Fasteners & Brick.2. Agricultural Tools, Hand Tools etc.3. Automobile, Motor Cycle & Bicycle Parts.4. Transmission Equipment.5. Engine Valve & parts, Watch Case, Cap.6. Wrist Band & Electric Equipment.

Birson Forging Screw Presses

Get Price Quote

We offer birson forging screw presses. These screw presses are specially designed to make bolt head of any kind of nuts, rivets, motor parts axle half shaft, engine valve and non-ferrous forging. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction.i.e. From bottom to top. On machines employing the vincent principle the screw nut is positioned in the top cross head of a frame type ram. Thus ram being moved upward in exial direction by rotation of longitudinally fixed screw. The bottom die of the forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frames but are sustained by the ram. Ejector is provided at lower part of the ram.