Automatic Fryer Machine

145,000 Per Piece

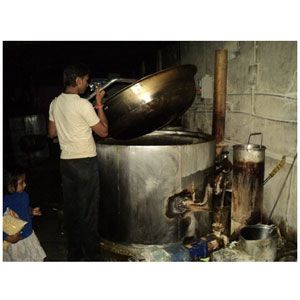

Circular Direct Heat Fryer Machine

350,000 Per Piece

1 Piece (MOQ)

Best Deals from Frying Equipment

Automatic Fryer Machine

1,003,000 Per Piece

1 Piece (MOQ)

Automatic Fryer machine helps in frying sweets and snacks evenly and gently without breaking them. It can be used for all kinds of food frying requirements. Used for Frying • Kachori • Lengcha • Gulabjamun • Kalajam • All types of frying Features • Small & compact in size • Castor-mounted for easy movement • Auto Ignition System • Automatic temperature control with a recipe setting • PLC based • Inbuilt twin gas burner Benefits • Energy-efficient machine • Easy to operate • No greasing/lubrication required for a lifetime • Hygienic operation • Huge labour & power-saving benefits • Low operate cost

cassava fryer

75,000 - 77,500 Per piece

.“NANS” Gari / Cassava roaster with automatic stirrer. Our “NANS” brand Gari roaster is specially designed for the African’s market. Heating unit is with the help of LPG (liquid petroleum gas), which make the roasting economical & therefore making the roasting profitable. Simple & easy to operate as it has a automatic stirrer. Capacity ranging from : 5 – 100 kgs per hour We are major Manufacturers & Exporters of Agricultural & Food processing machineries specially designed for the African market. The world renowned brnad owners of "NANS" & "REEJA". Country of orgin India. Africa's No:1 Brand "NANS" The only Manufacturers of complete Cassava processing plant in INDIA.

BATCH FRYER MACHINE

350,000 Per Piece

1 Piece (MOQ)

2 HP Mild Steel Wood Pellet Bhatti Fryer

190,000 Per Unit

1 Unit (MOQ)

Vacuum Frying Machine

200,000 Per Piece

fryer machine

115,950 - 155,950 Per Set

50kg auto fryer with electrical heating sytstem machine with motor &gear box standerd steel body portable plant oil tank capacity 80kg

Frymaster Oil Conserving Fryer

Get Price Quote

1 Piece (MOQ)

Frymaster continues its proud tradition of innovation, delivering fryers that are better for the environment, customer, worker, and the bottom line. Green benefits range from reduction of oil use to less energy consumption.

Stainless Steel Table Top Fryer

Get Price Quote

French Fries Bagging Station

Get Price Quote

Features: ◇Specially designed wire rack: any fall off chips slide along sloped panel and back to the tank. No waste!French fries bagging station ◇The perforations are of rectangular slots, on which a partition panel can be installed. It enables operator to separate different types of food (such as onion ring), thus you can use the same dumping pan for different types of fried food. No need to buy another piece of dumping pan. ◇Regardless of the actual position of the fryer, the accessories of the bagging station such as the rack, sloped panel, the upright glass panel etc. Can be positioned left or right to fit the position of the fryer. ◇The unit comes with heavy duty casters. Two with brakes. Accessories: ◇ Drip tray. ◇ Dumping pan partition. ◇ Wire rack.

Direct Heating Rectangular Fryer

Get Price Quote

Features Low fuel cost almost 20-30% less as compared to Traditional System. Low Electricity cost, 80% less as compared to Traditional System Automated temperature control that provide better and consistent product quality. Auto ignition Italian burners are fitted for heating

Vacuum Frying Machine

300,000 Per Piece

High vacuum frying machine, is the safr way of frying, resulting in the minimum acxrtlamide unlike open frying. The quality o9f the oil remains in good condition for several batches, resulting in tyhe more economy in the vacuum frying. Chemvac Engineers, W-146, MIDEC, Taloja-410208. Ph 9820032171

Namkeen Fryer

Get Price Quote

We are prominent Manufacturer, Exporter and Supplier of Namkeen Fryer. Our extensive range of Namkeen Fryer helps in frying the food items at a proper temperature for quality output. The entire range of Namkeen Fryer is made using optimum quality materials and cutting edge technology. Proper polishing is done by the experts before approving Namkeen Fryer for dispatching.

BATCH FRYER MACHINE

350,000 - 550,000 Per Piece

Circular Batch Fryer with Inbuilt Heat Exchanger

Get Price Quote

Heat Exchanger Circular Fryer For Potato/ Banana Wafer & Dal frying. We offering 48" Circular Fryer.The system is consist of : SS-304 Pan Diameter 48" Italian Ecoflam Burner (Diesel/ Gas) Electric panel board with temperature controller Bucket type automatic edible oil filter system Inbuilt Heat Exchanger 3 HP Pump & motors Features : The fryer is best suited for high temperature required product for Frying, such as Potato wafer, Banana wafer, Dal etc.

Potato Chips Batch Fryer

500,000 Per Piece

1 Piece(s) (MOQ)

Rectangular batch fryer with inbuilt heat exchanger, complete unit,

Medium Size Continuous Frying Machine

Get Price Quote

Medium Size Continuous Frying Machine ue oil water mixture technology have sediment removal system and conveyor is frequency adujstable. While frying sediment sink into water will be flow out along with water avoid beome black, hence it greatly extend the cycle life of oil. It has lifting system which is convenient to cleaning the belt and pot. It can use different heating source suit for frying time between 15 seconds tp 8 minutes. Technical Parameters: Model Heat mode PVG-XDL-3000 - Electric heating, Power 30KW PVG-XDL-3500 - Electric heating, Power 48KW PVG-XDL-4000 - Electric heating, Power 75KW PVG-XDL-4500 - Electric heating, Power 90KW PVG-XDML-3000 - Direct coal combustion PVG-XDML- 4500 - 150000 kcal heat carrier furnace PVG-XDDL-4500 - 150000 kcal heat carrier furnace Dimesnion and Oil tank size: Because of the different frying technics oil tank size and power shhoukd be adjusted according to moisture content and frying time of the products

Automatic Frying Machine

650,000 Per Piece

1 Piece (MOQ)

Continuous Namkeen Fryer Machine

Get Price Quote