Get Price Quote

Galvanizing Preflux, Clear Passivation Chemical

Get Price Quote

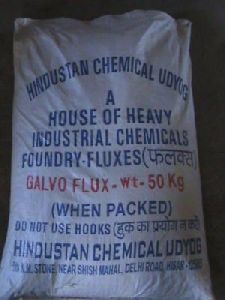

Galvo Flux (Triple Salt), Zinc sulphate monohydrate 35%

Best Deals from Galvanizing Flux

galvo flux

50 - 55 Per Kilogram

25 Metric Ton (MOQ)

During the hot galvanizing of steel pipes, tubes, steel structures and steel wires the zinc bath surface is in direct contact with the atmospheric air which oxides the zinc to form zinc oxide also called zinc Ash. This process of oxidation continues along with the galvanizing operation and after some time a thick bed of zinc oxide is formed over the entire surface of the zinc tank. The formation of zinc ash accelerates due to churning of dipping action. After some times a stage reaches when the zinc ash has to be removed and while removing it is observed that a big percentage of mechanically entrapped free zinc is also carried out, thus making the galvanizing operation extremely expensive. It has been observed that in some cases the consumption of zinc is as high as 9% to 11% to steel galvanized. The ash inclusior also given many a time rejections as they are picked up from the top of the bath during the withdrawal or the brunt ash may be carried on the steel during dipping causing rejection. Hindustan galvo flux Is a fumeless flux which not only covers the entire bath surface to protect the zinc oxide formation but also take care of the rejection during the ash inclusion. Hindustan galvo flux melt at 201 c which means as soon as the flux comes in contact with the bath is turns liquid which flows by itself on the tank and covers the entire surface. Hindustan galvo flux gives a foamy liquid cover layer which combines with the oxide particles and also gives a metal recovery action Hindustan galvo flux are free from Ammonium Chloride additions as is the case in the conventional fluxs. Hindustan galvo flux gives best results when there are galvanized around 450 c and galvanizing at higher temperature would only means higher consumption of the flux. ADVANTAGES OF HINDUSTAN CHEMICALS : a) Formation of oxide is reduced that to 2 to 2.1% as compared to 10 to 11% it the normal operation. b) Normally it is observed that a zinc oxide formation is 1.2 to 1.5% of the every day production, which is reduced to 0.2 to 0.3% of the steel galvanized object. c) Avoids the rejection due to ash inclusions. d) Helps giving brighter and uniform quoting on the galvanized object. e) Protects the surface of the production from cakes and stain. f) And lastly the flux does not give smoke which makes it very convenient to use in a very healthy we king atmosphere. Hindustan Galvo C.F.S. : This is a fumeless cover flux for the galvanizing of structure used for transmission towers and other similar purposes. HINDUSTAN GALVO C.F.T. : This is a fumeless cover flux for the galvanizing of steel tubes/Pipes and is applicable to all the process like star, screws manual operation. HINDUSTAN GALVO C.F.W. : This is a galvanizing cover flux for the steel wires, vessels etc. PRECAUTION FOR USE : a) Clean the bath and remove all possible zinc oxide before Hindustan galvo flux are added to the bath. b) In the first instance add only 0.5-0.6 kg per tonne for metal held in the bath. c) Give a baking time of 5 minutes before the inclusion started. This baking time is necessary only in the first addition. d) Kindly ensure that the foamy layer is atleast 1½ †thick. e) Fresh addition of small quantities should be made only when the flux layers starts getting thick. This addition is only the reactivating the old flux. f) Remove the old brunt flux as soon as it is noticed inactive. In normal operation this is down after 24 hours of operation. It is extremely important that the fluxes is not allowed to flow the exit and of the tank. The withdrawal of products should be from the clean zinc surface. Therefore incase of galvanizing of steel wires a portion wall should be provided. Do not leave the flux packets open to avoid moisture pick-up.

Galvo Flux

Get Price Quote

galvanizing flux, Tube Hydro Testing Machine, Slitter machine

Galvo Flux

Get Price Quote

galvanizing flux, Soldering Flux, Water Treatment Chemicals

Galvo Flux

Get Price Quote

galvanizing flux, Storage Tanks, Polypropylene Tanks

Galvo Flux

Get Price Quote

Galvanizing Flux Ni Base, Zinc Ammonium Chloride, Zinc Chloride Powder

Galvo Flux

Get Price Quote

Liquid Galvanizing Flux, Zinc Ammonium Chloride, Interlocking Tile Hardener

Galvo Flux

Get Price Quote

galvanizing flux, galvanizing chemicals, wax emulsion, Rice Bran Wax

Galvo Flux

Get Price Quote

Zinc Galvanizing Flux, Powder Pink Cover Foundry Fluxes

Galvo Flux

Get Price Quote

galvanizing flux, Zinc Chloride, galvanizing chemicals

Galvo Flux

Get Price Quote

galvanizing flux, Aluminum Powder, Sodium Dichromate, Sulphur Powder

Galvo Flux

Get Price Quote

galvanizing flux, metal treatment chemicals, Zinc Ammonium Chloride

Galvo Flux

Get Price Quote

galvanizing flux, Ortho Toluidine, Phenyl Ethyl Methyl Ether

Galvo Flux

Get Price Quote

Galvanizing Pre Flux, Radiator Flux, Soldering Flux, Zinc Chloride Solution

Galvo Flux

Get Price Quote

galvanizing flux, Cesium Carbonate

Galvo Flux

Get Price Quote

galvanizing flux, Zinc Chloride Powder, Zinc Chloride

Galvo Flux

Get Price Quote

galvanizing flux, Lithium Chloride Anhydrous, Sodium Succinate

Galvo Flux

Get Price Quote

galvanizing flux, synthetic polyelectrolyte, Hydrobromic Acid

Galvo Flux

Get Price Quote

galvanizing flux, Stainless Steel Pickling Paste, Synthetic Pitch Oil