High Velocity Galvanizing Furnace System

Get Price Quote

S M Engineering designs and delivers PULSE FIRED HIGH VELOCITY FURNACE that offers: Significant process Productivity benefits Fuel savings Improved temperature uniformity Lower NOx emissions Improved turn-down The key benefits of Pulse Firing are Low fuel consumption Low Ash and Dross Formation Uniform temperature distribution High Productivity Long Kettle Life Low in maintenance

galvanizing furnace

Get Price Quote

In the hot dip galvanizing process, the zinc is molten at the 450 °C or above temperature prior to immersing of the respective article and to achieve such a high temperature hot dip galvanizing furnace is essential, a furnace that is highly efficient, reliable and capable to heat the zinc kettle surface evenly. By owing the requirement of the highly efficient hot dip galvanizing furnace, Corrotech comes out with the hot dip galvanizing furnace made by leveraging our overlong experience in the allied industry along with the deep know how associated with galvanizing. This offered hot dip galvanizing furnace is fabricated using utmost quality mild steel that has a capability to withstand the high temperature changes, whereas casing of this hot dip galvanizing furnace is thickly insulated by exploiting supreme quality ceramic fibers and modules. The exclusive features that make our Hot Dip Galvanizing Furnace exclusive are: Low Fuel Consumption High Recirculation of Furnace Gases Uniform Temperature Distribution Optimum Heat Transfer Low Ash Formation Low Dross Formation Less Maintenance Cost

Best Deals from Galvanizing Furnace

Hot Dip Galvanizing Furnaces

Get Price Quote

Efficient Design Quality Light Weight Ceramics System of Kettle Support Minimum number of burners Reusable Furnace Life Extended Kettle Life Minimal Operating Costs Preassembled Furnace resulting in speedy and simple installation Commissioning on site personal to oversee installation, wiring, plumbing, start up

Galvanizing furnaces

Get Price Quote

Galvanizing furnace is the mainly fuel productive maintenance free furnace in the industry. The galvanizing furnaces are already earning a living for a with regard to over twenty years. Installing is easy, in addition to servicing price will be reduced its give small maintenance cost and also fully automatic constraint. Short production level, quick temperature reply, Choice of organizes system, quick equipment these are features of Galvanizing furnace. This equipment is provided more than 250 Galvanizing furnaces worldwide involved L & T in India. Large speed ending fired central heater technologies with gas and maybe oil fired options offer trusted services at the small preliminary price tag along with a really low upkeep price tag.

Hot Dip Galvanizing Furnace

100,000 Per Piece

1 Piece (MOQ)

Hot Dip Galvanizing Furnace

Get Price Quote

galvanizing furnace

Get Price Quote

Industrial Galvanize Furnace is a furnace in which the subject material is isolated from the fuel and all of the products of combustion including gases and flying ash. recognized for long working life, our range is used in foundry and mini steel plants for various processes such as such as calculation, ageing, homogenizing, baking, sinleing and heat treatment.

galvanizing furnace

Get Price Quote

We offer galvanizing furnace. Ferrotherm designs galvanizing furnaces with ‘high velocity burners’ that have long lasting proven performance on delivering high production volumes, low fuel & zinc consumption, high kettle life and requiring less maintenance. The furnace could be designed as dual fuel, oil only or for gas only as fuel. The furnace contains full control trains mainly equipped with controls, safety solenoid valves, piping & fittings imported from uk, germany, hungary and italy.

galvanizing furnace

Get Price Quote

M.G Furnaces offers excellent quality hot dip galvanizing plant on turnkey basis with flux, rinsing, quenching and other water tanks. We are considered as a prominent Hot DIP Galvanizing Furnace manufacturer, supplier & exporter based in India. We are offering our products in excellent quality & customized specifications in order to meet the exact requirements of the industry. Our experienced team uses superb quality raw materials while developing our products. Along with this, we also use cutting edge technology & advanced machinery during the manufacturing of our products. This helps us in providing international quality standards in our products.

Galvanising Furnace

Get Price Quote

Salient Features Horizontal, ‘L’ Shape, & Vertical Design Non-Ox Type Process Non-Ox Furnace suitable for processing very thin gauges (0.15mm) Non-Water Cooled Roll Design Gas Fired & Electrical Radiant Tube Section Horizontal & Vertical Soaking as per the requirement of product Jet Cooler with electric Heaters for processing thin strips Furnace Bridle to maintain differential Tension Furnaces suitable for GI & GL production Special design of Calm Zone for arresting of Zinc Fumes in case of GL production Heated Down Chute for GL Production Flexibility in operation Strip Temperature Control and Zone Temperature Control Protective Atmosphere Control

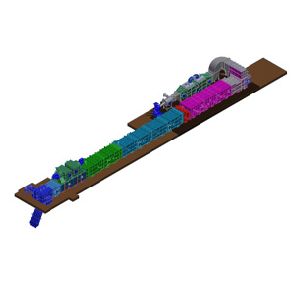

Furnace for Hot Dip Galvanizing Plant

Get Price Quote

APPLICATION : This is designed for galvanizing of Cable trays, MS structural, Poles and other miscellaneous items by Hot dipping in the zinc molten bath at 450 to 455 deg C. The general arrangement of galvanizing bath furnace shall be as illustrated in our enclosed drawing. DESCRIPTION The galvanized bath furnace offered is a Diesel / Gas fired with Steel kettle of special material used for melting of zinc and designed for continuous operation. The galvanizing bath furnace shall have a Kettle of size of 12,000 mm long x 1,500 mm width x 2,000 mm Deep.The Kettle is installed inside the pit suitably thereby bringing the operating level at about 750 mm from floor level. The furnace will be of indirect heating type with suitable chamber, burners and Blowers. Inspection pockets provided for inspecting the furnace chamber and kettle wall. Zinc drain pocket for drainage of molten zinc in event of kettle puncture. Burners will be suitable for Diesel or Gas. For controlling the temperature of molten bath we include an automatic temperature control system comprising of a digital temperature controller, thermocouple sensor and solenoid oil valves. The burners will automatically go fast and slow during the process whenever temp goes down, it will go fast and when temp goes high, it will slow as per the set off temperature. Due to this the consumption of fuel will be minimized. The Furnace consist of a refractory brick lined work using high quality alumina bricks. The galvanizing bath furnace is arranged for firing with 4 Nos. reputed make oil/gas fired burners with supporting Blowers, Control Valves etc. Electrical Control panel is supplied incorporating digital temperature controller and various electrical switchgear and is completely wired from inside and ready for connection to the mains. The galvanizing bath is capable of giving an out put of 50 – 60 tons/day. However the actual out put would vary considerably with the size, shape and weight of the steel structure and parts to be galvanized.

galvanizing furnace

5,000,000 Per Piece

1 Piece (MOQ)

galvanizing furnace

Get Price Quote

Galvanizing Furnaces to cater to different types of galvanizing applications both within India and abroad. These furnaces are designed after thoroughly studying the heat transfer dynamics and other requirements to ensure high thermal efficiency and long life for the zinc pot. May it be large continuous flux line or non-ox line, or a small batch type hot dip galvanizing process, or even a molten zinc holding system.Super Furnace has put in substantial efforts to develop and successfully install most efficient Galvanizing Furnaces to cater to different types of galvanizing applications both within India and abroad, - in countries like Indonesia, United Arab Emirates and Bangladesh.

galvanizing furnace

Get Price Quote

These furnaces are offered with combustion systems suitable for heavy oil, light oil, rich or lean gas or dual fuel (oil & gas). For special application electrically heated galvanizing furnaces are also offered.

galvanizing furnace

Get Price Quote

galvanizing furnace

galvanizing furnace

Get Price Quote

galvanizing furnace, Rotary Sand Cooler, Chute Conveyor, Tunnel Dryer

galvanizing furnace

Get Price Quote

galvanizing furnace, Controlled Atmosphere Braze Furnace

galvanizing furnace

Get Price Quote

galvanizing furnace, Hot Dip Galvanizing Plant

Galvanizing furnaces

Get Price Quote

Galvanizing furnaces, cnc turn mill components, mill component

galvanizing furnace

Get Price Quote

galvanizing furnace, heat treating furnaces, electrode salt batch furnace