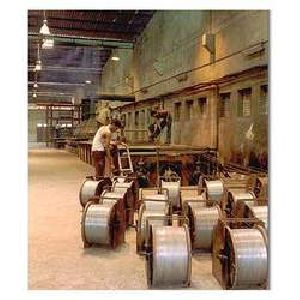

Wire Galvanising Plant

Get Price Quote

1 Container (MOQ)

galvanizing equipment

Get Price Quote

Galvanizing equipment furnace oil with a net calorific value of 10000 k. Cal.kg or gas. The chimney will be fibre lined. Air blowing is provided at the top of tanks.

Best Deals from Galvanizing Plant

wire galvanizing plant

Get Price Quote

Galvanized Wires offered by us are soft and used for earthing purposes, manufacturing of many wire products, such as Chain link, Stay wire, Barbed wire, Wire meshnetting etc. We have a wide variety, range, and quality of galvanized wires for different purposes and needs. Plants are run under the supervision of experienced technical team facilitated with lab support to ensure consistency in quality. We have three galvanizing plants using different techniques to meet the demand in the market with the weight range from 25 kgs to 600 kgs packed in rolls as per customer requirement.

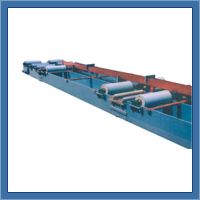

Inline Wire Galvanizing Plant

Get Price Quote

Arvind corrotech limited provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for galvanizing of high carbon and low carbon steel wires. arvind corrotech limtied has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide.

wire galvanizing plant

Get Price Quote

We hold expertise in manufacturing and supplying an exclusive range of Wire Galvanizing Plant. These products are fabricated using superior grade factor inputs, sourced from the reliable and certified vendors of the market. Our product range is extensively used for various industrial purposes and is widely appreciated by our clients due to its durable finish standards, high tensile strength and reliability. Our valuable clients can avail these products from us at the most affordable rates. Steel Wire Galvanizing Production Line Material: Low, high carbon Dia: 0.5mm - 12.5mm Wires: 8-40 Capacity: 1, 000 - 20, 000 Ton / Year We are instrumental in manufacturing and supplying superior quality range of Plants for Wire Galvanizing Plant (Hot Dip& Cold Dip). These are highly recognized for the features like durability and high tensile strength. Our product range is designed and developed using high grade factor inputs with advanced engineering concepts by our experts. These products are well tested on various quality parameters to eradicate all the flaws. Clients can avail these at the most competitive prices.

Cold Rolled Galvanizing Plant

Get Price Quote

We are a dynamically developing company that has evolved itself as a prime manufacturer and exporter of superior range of multifarious products such as galvanizing plant, pickling plants, pickling tanks and anti-corrosive equipment made from various industrial thermoplastics.

Hot Dip Galvanizing Plant

Get Price Quote

Hot dip galvanizing on the surface of Steel, aluminium and iron metal with zinc coating for long lasting and quality finishing by professionals as per the client's need and demand. Hot dip galvanizers used in the processing of galvanizing by our organization as Precimax online to deliver the best solutions that's why we are appreciated by our clients and clients positive feedback is our main assets. Galvanization is the process of coating defensive zinc coating on steels and irons into classify to find rusting, we take all cautions and supply and offer best to hot-dip galvanising plants since 1962 over more than 400 clients. Galvanizing equipments is the total option of products which is included as hot dip galvanising crash guard and guard rail, Galvanizing Plant, General Galvanizing Plant, Galvanizing Plant for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanising is design and developing for the utilizing high grade of raw materials and heavy hot dip Galvanizers machine in harsh conjunction with the industry set the norms and levels. Hot dip Galvanizing is usually very well tested in unique details in order that defect free products usually are sent from consumers' place. Hot dip Galvanizers give some advantaged like limited pickling time period, short manufacturing charge, reduced creation price tag, improved productivity etc.

wire galvanizing plant

Get Price Quote

Our organization specializes in offering a superior range of Wire Galvanizing Plant to our clients. These machines are facilitated with latest pickling system and fume extraction system and are also available in various sizes ranging from 5mm to 0.4mm. Our range of machines is ideal for M.S. and H.C. steel wires, electro and hot, and deep wire galvanizing plants.

Galvanizing Plant

Get Price Quote

Galvanizing plant ranging from 0.5 m to 13 m long manufacturer with pp tanks and pollution control equipments.

Hot Dip Wire Galvanizing Plant

Get Price Quote

We are engaged in manufacturing and supplying wide range of Hot Dip Galvanizing Plant to our clients. These products are manufactured using high quality basic material, procured from the trusted vendors of the market. Professionals of our team have manufactured these products in complete compliance with international standards of quality. These are widely demanded by our clients for their sturdy construction, excellent durability and reliable performance. Clients can avail these at affordable prices.

Galvanizing Plant

Get Price Quote

1 Piece(s) (MOQ)

We are offering steam boiler burner, dual fuel burner, gas burners galvanizing plant, Kettle, Steam reservoir

hot dip galvanizing plants

Get Price Quote

We are offering hot dip galvanizing plants. Plast world introduce ourselves as a leading manufacturer, supplier and exporter of a comprehensive range pickling tanks such as pickling plants for galvanizing tower , pickling plants for transmission tower, pickling plants for s.s. M.s. Pipes ,tubes , wire coils, stripe etc. We design pickling tanks that are used by galvanizing plants manufacturers for usage in high tension transmission tower , poles, pipe cable trays ,grating , guard, tails, railing and other steel items.

Hot Dip Galvanizing Plant

Get Price Quote

Arvind Corrotech is a leading supplier of turnkey hot dip galvanizing plants that guarantee great performance, productivity and efficiency. Starting from scratch by providing a customized design to commissioning, we get along with you in the process to set a high-performance galvanizing plant.

Cold Dip MS Wire Galvanizing Plant

60,000,000 Per unit

galvanizing equipment

Get Price Quote

Haryana Chemical Industries (HCI), an ISO 9001:2000 certified company, is one of India's leading manufacturers of Zinc Chloride and Galvanizing chemicals for the Galvanizing Industry. Founded in 1971 by Shri K.L. Kochar, We have over the years, grown from a Zinc Chloride commercial grade manufacturing company to manufacturers of a complete range of Zinc Chloride, Galvanizing, Galvanizing Flux, Hot Dip Galvanizing and Galvanizing Chemicals with wide applications and world-wide sales.

hot dip galvanising plant

12,000,000 - 20,000,000 Per Piece

1 Piece (MOQ)

hot dip galvanising plant

Get Price Quote

Hot Dip Galvanizing is the process of applying a zinc coating to fabricated iron or steel material by immersing the material in a bath consisting primarily of molten zinc. The galvanizing process has a distinct Advantage providing corrosion protection.

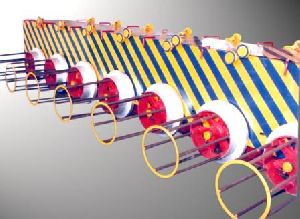

Hot Dip Galvanized Wire Plant

Get Price Quote

Assomac group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. Assomac has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead coil opener type Pay Off, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuperator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintenance required. Stainless Steel SS-316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criteria in today's plants. Zinc Bath furnace consisting of Structural Steel Frame which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for light / medium and heavy coating available. Zinc coated control through pad wiping, spring wiping for low & medium coating & vertical charcoal or nitrogen wiping for heavy coating can be provided. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical drop coiler with or without pattern lay and strip take ups in our manufacturing programe.

Scaffolding Galvanizing Plant

15,000,000 Per Units

wire galvanizing plant

Get Price Quote

East Land Industries is known to be a leading Steel Wire Galvanizing Plant manufacturer. These plants are facilitated with latest pickling system and fume extraction system and are also available in various sizes ranging from 5mm to 0.4mm. Our range of machines is ideal for MS & HC Steel wires, electro and hot, and dip wire galvanizing plants. We provides our customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups.

Hot Dip Galvanizing Plant

Get Price Quote

Reduces Maintenance. Increases life of Products. Cuts off Painting costPipe. Plates. Poles. Metal Beam Crash Barriers. Tubes. Nuts & Bolts etc.

Hot Dip Galvanizing Plant

Get Price Quote

Hot dip galvanizing plant, The manufacturing process in nutshell can be described as under:The steel articles are dipped into "Caustic Soda Solution" for "Degreasing"The load is again rinsed in "Rinsing Tank" containing clean water. Next step is "Pre-fluxing" wherein the material is dipped in "Pre-Fluxing" tank containing "Zinc Ammonium".

Stainless Steel Plating GALVANIC PLANT

Get Price Quote

Plant equipped with 4 tank in pyrex lt.2 each, separately powered, degreasing tank with fixed voltage of 7,5V 12A, rhodium tank with adjusting voltage from the pontetiometer on the command panel from 0-5.0V 8.0A with electronic protection against brown out and the short-circuit with automatic restore. Double heating optional with 2 separate temperature controls. The machine include 2 adjustable current clamps from 5.0V 8.0A, inox anodes for degreasing and titanium net for rhodium. TECHNICAL FEATURES : Command panel with electronic voltage control. Rectifier power 12A-7.5V. Nr. 4 tanks of lt.2 in pyrex diam.130mm. Mechanic working timer. Warmer for rhodium 400W. Hook of Rhodium.

wire galvanizing plant

Get Price Quote

Buyers can consider us, if they are looking for a cost effective and excellent quality range of Wire Galvanizing Plant. The offered product range is designed and developed by using the top-notch quality material, thus ensures the quality. Sturdiness, longevity and cost effectiveness are some of the key attributes, which make our Wire Galvanizing Plants high in demand among the global buyers.

galvanic plant

Get Price Quote

We are one-step ahead of our counterparts in offering a comprehensive collection of Galvanic Plating Plant. These products are developed from supreme-class components which are obtained from reliable vendors of the market. Due to technically advance characteristics and reliability, these products are widely needed by many numbers of customers. We provide these products in many models.

hot dip galvanising plant

Get Price Quote

Surface preparation is the most important step in the application of any coating. In most instances, where a coating fails before the end of its expected service life it is due to incorrect or inadequate surface preparation. With galvanizing, the surface preparation process contains its own built-in means of quality assurance and quality control in that zinc will simply not react with a steel surface that is not perfectly clean.

wire galvanizing plant

Get Price Quote

Star Tech Industries is known to be a leading Steel Wire Galvanizing Plant manufacturer. These plants are facilitated with latest pickling system and fume extraction system and are also available in various sizes ranging from 5mm to 0.4mm. Our range of machines is ideal for MS & HC Steel wires, electro and hot, and dip wire galvanizing plants. We provides our customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires.

Hot Dip Galvanizing Plant

Get Price Quote

We use SEO as an effective tool to promote your business, brand and products or services. Product keywords of clients are found on the first page of Google. Products like Hot dip galvanizing plant, acid fume extraction system, zinc white fume extraction system, pre treatment plant, post treatment plant, post treatment plant, acid storage tank are seen on the top search results of different search engines.

hot dip galvanizing equipment

Get Price Quote

The Keya Plast can supply as per your requirement with Pickling Plants Heating System, Protection bar against damage, Fume Exhaust & Scrubbing System, Hood, Ducting, Chimney & Canopy, Pipe separator system in tank, Load hanging system on tank, Tank covers lid, Integral Fume Ducting, Acid Circulation System, Installation Stat-up Training, etc. The Pickling Tanks are used for Galvanising Pipes & Tubes, Wires & Rods, Bars & Profiles, Sheet, Strip & Coils, Transmission Tower Structure, RCC TMT Rebars, Highway Guide Rails, Electric Poles, Electrical Overhead Hardware, Grating, Cable Trays, Wire Ropes, etc.

Galvanized Wire Plant

Get Price Quote

Meenakshi Wire Products provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. MWP has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to ourcustomer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead Coil Opener type Payoff, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuparator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintence required. Stainless steel 316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criterion in today's plants. Zinc Bath furnace consisting of Structural Steel Frame. Which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for Light/medium and heavy coating available. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical dropcoiler with or without pattern lay and strip take ups in our manufacturing program.