GAS BASED CREMATION FURNACE

1,800,000 Per piece

1 piece (MOQ)

Gas Fire Furnace

Get Price Quote

Our Gas Fire Furnaces designed for temperature up to "1400 Deg C" are sought after by the global clientele for their innovative design and unerring performance. Also, their fabrication from the grade raw materials enhances the durability of these Furnaces. We facilitate the clients by offering these Gas Fire Furnaces in ample specifications at the marginal rates. Also, we are accoutered to fulfill every consignment within the prescribed time. Furnace are designed for various applications like : Heat Treatment Melting Continuous and Batch Type application Features : Uniform temperature within the furnace Completely automatic with Controls High quality insulation Robust design

Best Deals from Gas Furnace

Gas Dust Burnout Furnace

Get Price Quote

1 Piece (MOQ)

iron electric industrial gas furnace

195,000 Per Piece

1 Piece (MOQ)

Gas Firedoil Fired Boogie Hearth Furnace

Get Price Quote

1 Piece (MOQ)

Gas Cremation Furnace

5,100,000 Per Piece

1 Piece (MOQ)

Gas Fired Melting Furnace

2,500,000 Per Piece

gas carburizing furnace

Get Price Quote

gas fired furnace

2,000,000 Per Unit

JRFURNACE is reputed as one of the trusted Pulse Fired High Velocity Fuel Fired furnace manufacturers for optimum performance. Fuel fired furnaces are fired with high efficiency burners supported by a full complement of combustion system consisting of combustion fan, atomizing fan, oil heating and pumping systems and/or gas trains.

gas fired furnace

Get Price Quote

Gas fire furnace suitable for studio pottris available 1050 to 1200 digri tamprature.

GAS BASED CREMATION FURNACE

18,000 - 23,000 Per piece

1 Piece (MOQ)

=

Gas Fired Rotary Furnaces

Get Price Quote

500 Kilogram (MOQ)

we are offering gas fired rotary furnaces, indotherm equipment is leading manufacturer, exporter of rotary furnace rotary furnace is one of the best traditional furnaces used is smelting and melting in areas of foundry. rotary furnace comprise of various tools such as furnace shell, drive system (mechanical) insulation refractories combustion equipment's such as burner, centrifugal combustion blower and various accessories. commonly areas of application: lead smelting, lead refining industries, aluminum melting and smelting process. advantages over tilting furnace: less automation easy in maintenance. crucible is not required. produces more maintains heat within generates heating time faster is good heat exchanger or recuperator is installed. needs single operator. also know as: gas fired furnace| oil fired furnace| aluminium melting rotary furnace| lead melting rotary furnace| non ferrous melting furnace| rotary kiln| high temperature furnace popular tags: rotary furnace aluminium recycling |rotary furnace for cast iron melting| rotary furnace for lead smelting| rotary furnace design| rotary furnace manufacturers| rotary furnace pdf| rotary furnace for sale

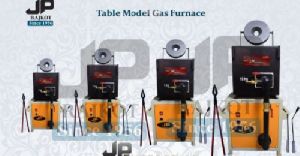

JP Table Model Gold Melting Gas Furnace

Get Price Quote

1 Piece (MOQ)

gas fired furnace

Get Price Quote

This direct Natural Gas Fired Reverberate type rotary furnace is a non-crucible continuous revolving type with a stationary burner arranged at one end for melting of having 170 kg batch capacity.

Gas & Oil Fired Bogie Hearth Furnace

Get Price Quote

We offer Gas & Oil Fired Bogie Hearth Furnace. Bogie Hearth Furnace Source- Gas Oil Electrical. Application - All Heat Treatment Application. Max Temp- in Gas Oil - 1440 Deg C. Max Temp in Electrical- 1200 Deg C.

Gas Nitriding Furnace

255,000 Per Piece

Pit Type Gas Carburising Furnace

Get Price Quote

1 Piece (MOQ)

We are offering pit type gas carburising furnace. These pit type carburising furnaces are designed to suit standard sizes and to suit customer requirements. Robust construction, long heating element life and sealed carburising atmosphere are the basic features of our designs. Apart from above. Low energy consumptions is achieved by using optimal insulation arrangement. The carburising carbonating nitro carburising atmosphere is automatically maintained using oxygen probe and control system.

Gas Furnace

40,000 Per Piece

gas carburising furnaces

Get Price Quote

We are serving for last 51 years with our high quality electrical operated industrial heat treatment furnaces,bell type or box type normalizing furnaces,tempering furnaces,annealing furnaces,shaker hearth furnaces,continuous heat treatment furnaces,rotary furnaces,gas carburizing furnaces,hardening furnace,industrial ovens,melting furnaces,burn out casting furnaces,ammonia cracker furnaces,heating furnaces,baking ovens,controlled atmosphere furnaces,nitriding furnaces,bright annealing furnaces, lab furnaces,high temperature furnaces,muffle furnaces with thyristor scr panel ,automatic ramp and soak feature and maintaining heating rate cycle,programmer p.i.d controller muffle furnace,hot tensile testing furnace with double zone independent control,spectro sample polishing machine,argon purifier furnaces,heating elements,thermocouples,carbon sulfur apparatus and quality lab metallurgical testing equipment,lab ovens,air circulation ovens and lab testing equipment etc.

gas carburising furnace

Get Price Quote

A gas carburizing furnace is also known as pit-pot type furnace this type gas carburizing furnace is used for increasing the surface hardness of steel such as auto parts, gears, precision turned components, construction machinery parts and any other component needing hardening. a temperature of this furnace is automatically controlled, hydraulic lifting and the drip feed of carburizing fluid. The furnace may be heated electrically, oil fired or gas fired. Thermocouples, Industrial oven, Electronic controllers, industrial furnaces, industrial heating elements, ceramic wares, electronic temperature controllers and industrial lab equipment are major products delivered by KSM, the lab equipment suppliers in chennai. Our precision, accuracy, and performance stand as best in the industry and we have won accolades for that. We proudly say that we have been servicing industries in several countries and achieved great customer satisfaction. Our quality process ensures the best deliverables resulting in world-class equipment for our customers. The costs are maintained at an affordable level and service support continues to be our major strength. Industrial furnaces are heat generating equipment and they find application in several different types of processes. The heat would be produced by fuel combustion or by using electrical energy. They come in different types based on temperature, heat source, the method of firing, recirculation etc. Industrial applications of industrial furnaces can be listed as soldering, sintering and heat treatment.