Gas Scrubbers

400,000 Per Piece

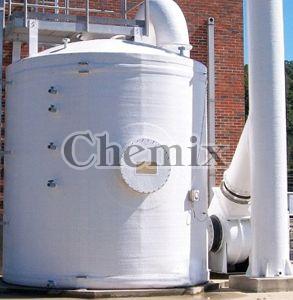

Chemix Specialty Gases And Equipment: ISO 9001:2015 certified company manufactures gas scrubbers for industries. This equipment removes dust, odor, and other gaseous components from the gas in industrial exhaust streams. It is generally an air pollution control device based on simple technology and offers the advantages of easy installation, simple maintenance, and high disposal output. This type of equipment separates dust as well as poisonous gases from the gas in the gas cleaning process. The substances harmful to the environment are either neutralized or removed. Customers can get in touch with us to buy energy-efficient, dimensionally accurate gas scrubbers.

Wet Gas Scrubber

Get Price Quote

We are counted amidst the most reliable manufacturers and exporters of a huge gamut of Wet Gas Scrubber that is manufactured using cutting-edge technology. There is completely no other alternative to the range of Wet Gas Scrubbers that we offer in terms of reliability, tensile strength or performance. These Wet Gas Scrubbers are resistive to even adverse conditions and owing to their durability they are widely demanded by the clients. Easy to operate, the Wet Gas Scrubber manufactured by us requires zero maintenance. Popular For : Sturdy construction High performance Superior functionality Complete finishing Longevity Advantages : Apt for inflammable and explosive products Less than 60 mm of WC Draught loss Particulate removal and absorption at the same time Gas cooling Installation may be done before or after ID Fan Colorless flow gas going to chimney and with particulate less than 150 mg / NM3 The inlet and outlet of the flue gases are from the top of the scrubber, which avoids any water passage to ducting or air heater No power driven running part The system consists of instrumentation for temperature control of outlet gases which save the I.D. Fan. The outlet gas temperature shall be around 95 ± 5 deg. C.

Best Deals from Gas Scrubbers

Mobile Gas Scrubber

70,000 Per per unit

1 per unit (MOQ)

Gas Scrubber in Glass

250,000 - 850,000 Per Set

2 Sets (MOQ)

Gas Scrubbers

Get Price Quote

Gas Scrubber

Get Price Quote

1 Unit (MOQ)

Features Removes very fine dust particles Controls 𝑆𝑂𝑥& 𝑁𝑂𝑥 Maximum contact of water with gases Cleans dust particles collected in demister Highly efficient spray nozzles New design & concept

Fume And Gas Scrubber

Get Price Quote

FUME and GAS SCRUBBER For Particulate collection & treatment of harmful gasses in chemical, fertilizer, textile & material treatment Industries. Various design offered include direct contact, Ventury, High fog, Bubble bath.

Fume And Gas Scrubber

50,000 - 650,000 Per Piece

1 Piece (MOQ)

Gas Scrubber

Get Price Quote

10 Set(s) (MOQ)

We offer gas scrubber. A gas scrubber is a piece of equipment designed to purify a plume of gases before it is released into the environment. Pollutants are removed from the plume, allowing for the venting of harmless compounds while the dangerous ones are trapped for sequestration and disposal. Scrubbers are required by law in settings where people work with potentially polluting gases, and there are several designs available for various applications. one type of gas scrubber is a wet scrubber, where a liquid, often water, is introduced into the ventilation stack. The liquid is commonly sprayed, or aerosolized. It traps particulates in the gas and reacts with compounds in the gas, carrying them down to the bottom of the stack. The liquid pools for storage, at which point it can be run through a wastewater treatment plant and reused or otherwise processed to control the pollutants. It is common to see a visible plume when a wet scrubber is used, as some humidity is created. in a dry gas scrubber, a compound is introduced in the form of a gas or powder. The compound clings to certain molecules in the escaping gases, trapping them so they cannot be released into the air. It is designed to sink or be transported through controlled vents, purifying the gases as they rise through the stack. The plume in this case may not be visible when it emerges from the stack, as particulates should be removed and humidity levels stay stable. scrubber systems usually need to be designed for specific applications, keeping in mind the type of pollutants involved and the volume of production. The scrubber must be designed to cope with peak loads without failing, as a shutdown of the stack could be extremely costly and, in some cases, dangerous. Scrubbers may also be fitted with filters and other devices, along with air quality monitoring systems for the purpose of confirming that they are functioning properly by removing hazards from the air and releasing only clean air into the environment. increasing clampdowns on permissible pollution in many regions of the world have forced companies to be innovative about pollution control. Gas scrubber design is constantly under improvement as people work on new systems for pulling out impurities in the air. Regulations are often designed to promote improvement through incentives or the establishment of deadlines for companies to meet new air quality standards with gas scrubber equipment and other anti-pollution measures.

Gas and Fume Scrubber

Get Price Quote

Gas Scrubbers

Get Price Quote

FRP Gas Scrubber

Get Price Quote

We cater to the demand for FRP Gas Scrubbers from anywhere across the country and abroad. We are a reputed Manufacturer and Supplier of FRP Gas Scrubber in Haryana. We produce the Scrubber using the quality materials, which we procure from named vendors. And being FRP-based, the Scrubber is corrosion resistant and durable. Its quality is tested and assured by our team of quality controllers.

Gas Scrubber

115,000 Per Piece

Gas Scrubber

Get Price Quote

1 Set(s) (MOQ)

We manufacture and supply scrubbers including internals like packing's with supports, demister pad with supports and spray piping we design and manufacture gas scrubbing system to suit client’s requirement. gas scrubbing systems are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. the gas scrubbing systems are designed for scrubbing the gases like hcl / h2so4 / so2 / so3 / br / cl2 /etc. size : 100 mm ø to 3000 mm ø types of gas scrubbers : packbed scrubber. venturi scrubber. cyclon scrubber.

Gas Scrubbing System

Get Price Quote

1 Set(s) (MOQ)

Our provided scrubbing systems are a diverse group of air pollution control devices that can be used to remove some particulates andor gases from industrial exhaust streams. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term is also used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation. the type of scrubbers we provide packed bed columns. Wetting well columns. Venturi scrubber. Spray tower.

BOILER FLUE GAS SCRUBBER

150,000 - 220,000 Per Nos

1 Nos (MOQ)

A Boiler flue gas scrubber, often referred to as a flue gas desulfurization (FGD) system, is a technology used to remove pollutants, primarily sulfur dioxide (SO2), from the exhaust gases generated by industrial boilers, power plants, and other combustion sources. The primary purpose of a boiler flue gas scrubber is to reduce air pollution and comply with environmental regulations. Boiler flue gas scrubber working process: 1.Gas Absorption: Flue gas containing pollutants, such as SO2, is directed through a contactor or absorber vessel. 2.Absorbent Solution: In the absorber, the flue gas comes into contact with an absorbent solution, usually a liquid slurry or a chemical reagent. The most common absorbent is limestone (calcium carbonate), which reacts with the SO2 to form calcium sulfite or sulfate. 3.Chemical Reaction: The chemical reaction between the absorbent and SO2 converts the sulfur dioxide into a less harmful compound. This reaction is typically represented as follows: SO2 + CaCO3 (limestone) -> CaSO3 (calcium sulfite) + CO2 4.Removal of Solid Byproducts: The calcium sulfite or sulfate formed in the reaction is separated from the absorbent solution in a solid-liquid separation unit. The remaining liquid can be recirculated for further use. 5.Waste Disposal: The solid byproducts are typically treated as waste and disposed of or used in other applications.

Mobile Gas Scrubber

125,000 - 451,000 Per Set

1 Set (MOQ)

UD offers mobile scrubbers fabricated in all glass The UMS 100/150 is an all glass model mobile scrubbing system for laboratories. The system is mounted on SS tubular supporting structure and is maneuverable easily. The UMS 100/150 Scrubber consists of: Glass reservoir for the circulating media Magnetically coupled seal-less PP centrifugal pump Borosilicate glass coil type cooler Packed column of Borosilicate glass with glass raschig ring Technical Specification Model UMS 100 UMS 150 Gas suction capacity 12 m3/hr maximum 50 m3/hr maximum Reservoir Borosilicate glass flask 20 liter capacity Borosilicate glass flask 50 liter capacity Circulation pump 3m3/hr, 20 m head, Poly Propylene pump magnetically coupled to 1.5 kw 2800 rpm electrical induction motor suitable for operation in flame proof environment 5m3/hr, 20 m head, Poly Propylene pump magnetically coupled to 1.5 kw 2800 rpm electrical induction motor suitable for operation flame proof environment Cooler 1.5 m2, coil type made of Borosilicate glass 2.5 m2, coil type made of Borosilicate glass Scrubber column Borosilicate glass 100 mm diameter x 1000 mm ht Borosilicate glass 150 mm diameter x 1000 mm ht Interconnected piping and valves Borosilicate glass Borosilicate glass Mounting structure Stainless Steel tubular structure and fittings Stainless Steel tubular structure and fittings Overall dimensions 1000 x 1000 x 2340 mm ht 1000 x 1000 x 2400 mm ht

Acid Gas Scrubber

Get Price Quote

We are a leading Manufacturer of gas scrubbers and bioscrubber from Tarapur, India.

Gas Scrubber

100,000 Per Piece

1 Piece (MOQ)

Gas Scrubber

75,000 Per Piece