Ceramic Embedded Rubber Liner

10,000 Per Piece

1 Piece (MOQ)

Deflector Liner

8,500 Per Piece

10 Piece (MOQ)

We introduce ourselves as Manufacturer and Supplier of POWER PLANT SPARES for BOILER, RAW MILL, BOWL MILL, COAL MILL, ASH HANDLING, ESP Made of Carbon and Alloy Steel, Wear Resistance Cast Iron and Steel Casting, Copper based Phos . Bronze, Gun Metal , Brass, Nickel Alloy, Mild & Stainless Steel & Fabrication . List of Power Plant Spares manufactured :- Economiser Sheild Sprocket plate for RC Feeder Manhole Door Bearing Bush of Vertical Shaft Sheave Shaft for Clinker Grinder Feeder Sideliner Gland Follower of Clinker Grinder Seal Plate Slide Gate Bowlwaer Plate Hub for Clinker Grinder Cover Top for Vertical Shaft Drum Classifier Cover Pulveriser Drive Sprocket of Clinker Grinder Holder Vane Classifier Basket Supporting Grill Coal Burner Pipe Nozzle Rim Chain Pulley Drive Pinion Motor Transmission Coupling Safety Valve Compressor Hallow Screw Boiler Drum Manhole Fixing Device Manhole Clip For LTSH Coil KIT for Roller Assly Crusher Mess Plate Shaft Campring Element Sun Gear Tail End Guide Roller Drive & Driven Shaft Intermediate Shaft Pump Shaft Shaft Sleeve Cone Coupling for HP Waste Pump Oil Ring Collar for ID Fan Core Air Tube Support Spide Guide Ring Shaft Hallow Output for Coal Feeder Flight Bar Bearing Housing Diaphram for ID Fan Coupling Feed Tube & Screw Grill/ Gratin Step Super Heater Spacer Shaft for Damper Valve Disc Drive Shaft for Holding/ Unloading Head Sprocket Shaft for Bucket Elevator Tail Sprocket Shaft for Bucket Elevator Bowl Wear Plate/ Bowl Extension Ring Modified Stud & Nut Seal of Mill Side Housing Seal Aluminium Bronze Ventury Drum Ventury Collar Slide Gate Clinker Grinder Motor Half Hub Gate Slide (Plate) for Hot Air Gate Sleeve Shaft Clinker Grinder Slide Gate of 6" Knife Spacer of Clinker Grinder Roller Shaft Holder for Van Classifier Sprocket Plate for R.C.Feeder Gland Followers Bottom Hopper Access Door Hub for Semiflex Coupling feed Chute Plate Liner Value Body Assly Pilveriser Roll Drum for Pulveriser Sprocket Cum Hub for R C Coupling of Mill Threaded Hub for R C Coupling of Mill Feeder Gland Seal Drum Classifier Cover Pulveriser Throat Tail piece Hydro Ejector Ash Plant Wear Piece Hydro Ejector Ash Plant Collar Ventury Nozzle Plate for Hydro Ejector Ash Plant Grinding Roll Keeper Plate Scraper Arm Gear for Vibro Feeder GI Ladder Type Cable Tray Roller Screen Sprocket Shaft Roller Screen Drive End Sprocket Crusher Mesh Plate for Coal Crusher/ CHP Grill for Side Truck Hopper for CHP External & Internal Lever for Coal Mill Lower Tie Rod for Mill Load Frame Coal Mill Upper Tie Rod for Mill Load Frame Coal Mill

Best Deals from Geosynthetic Clay Liners

Wear Resistant Rubber Liners / Chute Liners

5,000 - 20,000 Per Piece

10 Piece (MOQ)

Geosynthetic Clay Liners

175 Per Square Meter

1000 Square Meter (MOQ)

GEO CLAY LINER are geo composite that are manufactured with a betonies clay sandwich between to top and bottom geotextile where in one layer is woven geotextile & other is needle punch non woven geotextile. APPLICATION Hazardous Solid Waste Land Filled Municipal Solid Waste Land Filled

Radial Lifter Bar

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber Lifter Bar – Make Your Milling Process Efficient & Smooth with Our Utmost Quality Lifter Bar Kedar Rubbers offers high quality rubber products including the best quality Lifter Bars (Radial and Trapezoidal), which are essential components of ball mills. Our top-quality lifter bars play an important role in making grinding processes efficient by improving the grinding media and materials' tumbling action. Thus, the key functions of lifter bars are to lift the grinding media and materials that ease the movement, protect the mill shell, reduce the noise level, and enhance the grinding & milling efficiency. Selecting the right dimensions and designs of lifter bars can significantly impact the performance and cost-effectiveness of the milling process. Uses Our lifter bars comprise excellent resilience and wear resistance and are broadly used in different milling applications in industries, such as Mining, Metal, Cement, and Ceramic where it is required to deal with hard ores or abrasive materials. At Kedar Rubber, we deliver radial and trapezoidal lifter bars based on precise customer specifications (design, height, angle, radius, etc.). We provide the best quality lifter bars according to the customized needs of your milling processes to lift and drop the grinding media. For more information or your custom inquiry for ball mill lifter bars, write to us at kedarrubber@gmail.com or Call Now - 9824444733. All About Radial Lifter Bar – Installation, Functionality, and Design With the foolproof installation of radial lifter bars, they enhance the working efficiency of ball mills. They are installed alongside the inner edges of the mill shell normally parallel to each other. The vital factors necessary to consider for perfect installation are secure attachment and accurate alignment, which make certain that the installation performs effectively and prevents imbalance or excessive wear. As the mill rotates, the radial lifter bar lifts and moves the grinding media and material in a radial direction (from the bottom of the ball mills to the top). This movement efficiently mixes and grounds the charge, continuously. Thus, the ball mill grinding efficiency and impact are enhanced with such lifting actions that help to cascade the grinding media. Radial lifter bars are specifically designed for ball mills that support clockwise or anticlockwise rotation (which depends on the direction of rotation and design specified for the ball mills). Thus, radial lifter bars support both clockwise and anticlockwise rotation helping in increasing the lifespan of ball mills. The design and angle of the radial lifter bars are vital factors for their efficient performance. Lifter bars' orientation with the mill’s rotation direction is necessary to consider for optimal grinding efficiency. Accurately designed lifter bars make certain that the grinding media gets the precise trajectory to grind the material resulting in the desirable particle size. Our Radial lifter bars give consistent grinding with uniform lifting and dropping action of the grinding media. They reduce the overall time for grinding processes, improve performance, and become a cost-efficient solution for ball mills. Trapezoidal Lifter Bars The trapezoidal profile plays a vital role in making the grinding process efficient by influencing the movement of grinding media and material in the ball mills. They improve the lifting action using higher and angled edges that give an aggressive lifting angle compared to rectangle lifter bars. It allows lifting the charge towards the up direction within the mill and then letting the balls and material drop from the top of height to create higher impact pressure. Thus, such actions make the grinding process more efficient for breaking down material. Besides trapezoidal lifter bars boost the dropping motion necessary for properly mixing and uniformly distributing the grinding media and material throughout the ball mill. Thus, it well-manages the motion that improves the milling process by increasing the contact between the material and balls which results in reducing particle size consistently. They require less time to process significant amounts of material. All About Lifter Bars - With & Without Metal At Kedar Rubber, we provide lifter bars with and without metal based on the tailor-made needs of customers as per their milling applications. Lifter Bars with Metal Lifter bars with metal are best applicable in ball mills for their utmost durability, and capability to withstand the intense wear and impact due to abrasive and hard material grinding, thus offering primary grinding benefits. They can manage abrasive materials and high-impact forces. The superior lifting capability of metal lifter bars enables maintaining a continuous and effective trajectory for the ball mill’s grinding media. This improves the quality of the products, grinding performance, and higher materials. Lifter Bars without Metal With some characteristics like energy efficiency and noise resistance, Lifter bars without metal are best applicable for fine and secondary grinding applications of ball mills. As made from rubber, non-metal lifter bars reduce energy consumption as they decrease the load on the motor. They are suitable for regrinding (secondary) grinding, where they require low-impact force and minimize wear and tear. Thus, lowering the operating cost and increasing the lifespan of equipment.

Agricultural Ponds Liners

Get Price Quote

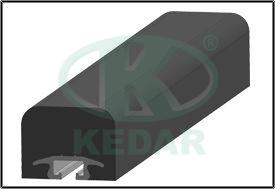

RUBBER EMBEDDED CERAMIC LINER

2,500 - 3,000 Per Piece

20 Piece (MOQ)

Rubber Lifter bar

Get Price Quote

100 Piece (MOQ)

Our wear bars (also known as lifter bars) are used for grinding mills as stock items. These bars comprise of aluminium T bolt profile and wear resistant rubber. The aluminium profile vulcanized into the bar allows fast and easy installation due to the T-bolt fastening system. Wear bars are excellent wear lining to; washing drums, rock boxes, feed cone-crushers and other applications subject to wear and noise. The standard length available is 1520mm, in thicknesses ranging from 75mm to 150mm.

Geosynthetic Clay Liners

Get Price Quote

Geosynthetic Clay Liners (GCLS) are high performance needle punched environmental reinforced composites, which combine two durable geo textile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier. Fibers from the non-woven geo textile are needle punched through the layer of bentonite and incorporated into the other geo textile (either a woven or non-woven).when hydrated under a confining load, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay. The Geosynthetic Clay Liners is used to prevent water leakages in areas of artificial lakes, waste disposal fields, underground garage, top building gardens, reservoirs, oil warehouses, and chemicals accumulating fields. Features Improved leakage performance Permanent waterproof performance Simple construction and short time limit for a project Not influenced by air temperature A kind of green material and good to environmental protection More versatile than compacted clay Increased airspace and liner efficiency

Rubber Frame Plate Liner

Get Price Quote

5 piece (MOQ)

Rubber Liners

200 Per Kilogram

1 Kilogram (MOQ)

We are among the prominent suppliers, wholesalers and traders of a wide range of Rubber Liners. These are widely used for industrial purposes; wherein there is a possibility of accidents due to electric shocks. These help in making the work environment safe. We provide them in dimensions specified by the customers. These have been reasonably pricedSpecifications: Material: HDPE, LDPE, LLDPE, HDPE, EVA, ECB, PVC , CPE standard: ASTM thickness: 0.1-4.0 mm width:1-7 m

plastic liners

100 - 120 Per Kilogram

100 Kilogram (MOQ)

Sugra Mill Spray Ponds system

10,000 - 100,000 Per Piece

1 Piece (MOQ)

Products Information Cooling Efficiency: The extremely smooth inside surface finish brings frictional losses to practically zero. S S inserts provided at the discharge end, ensure a uniform spray and avoid deformation. Thus, the system is perfectly designed for a definite temperature drop of 10.c. to 11.c. as the microfine atomized spray created by our micro spray nozzles, offers high surface contact with the ambient air. Under computerized automation of our condensers, system can give a temperature drop up to 15.c.-16.c Highly Economical Due to the special quality of Isophthalene Engineering Polymer used as raw material micro spray nozzles, clusters are resistant to erosion and corrosion. The result longer life, compared to other systems using ordinary thermoplastics. Effect of Sunlight Our Isophthalene Engineering Spray Pond equipment, withstands the action of sunlight effortlessly, due to the special grade polymer used as raw material. Traditional spray pond systems including mist cooling need CI / PVC Tee on every civil column for installation of Five Way Cluster. We have developed a unique Five Way Cluster that can be directly screwed into F.T. console fitted on branch. This eliminates a no. of SS / MS nut bolts, jointing packing. This facilitates maintenance cleaning of nozzles etc. During off season the entire cluster can be unscrewed, each nozzle can be unscrewed even special F.T. console can be taken out for cleaning purposes. Cooling Efficiency The system is designed to suit low head spray pumps of 10/12mtr head hence power requirement at the spray station is 35% lower compared to cooling towers with induced draft fans. Gravity Flow Micro Spray Water Cooling System Gravity flow spray pond facilitates elimination of spray pumps. Condensers are installed at a height of about 22mtrs & hot water coming out of tail pipes is collected in a common header (installed at 10mtrs height from G.L.) & this header is directly connected to spray pond common header. This system is very effective & saves on power. Branch Lines are of special grade u/v resistant PVC helps reduce frictional losses. Only one flange joint at start of branch line. Main line fabricated from SS (409 / 304) ensures maintenance free life of over 15 years. Due to SS as material of construction scaling, corrosion shall be eliminated.

hdpe pond liner

6 - 10 Per Square Feet

1000 Square Feet (MOQ)

500 micron HDPE pond liner.

Rubber Milk Liner

400 - 600 Per set of 4 pcs

50 Sets (MOQ)

Printing Machine Liner

Get Price Quote

Wear resistant rubber liner

6,000 - 7,500 Per Piece

100 Piece (MOQ)

we manufacture rubber liner ,lifter bar, for ball mill for iron ore , ceramic ball mill , we do installation also

coloured plastic liners

Get Price Quote

We are assisted by a team of professional quality experts who check our products at different stages such as production, packaging and delivery. Product packaging is done using industrial grade materials by us to ensure safe and undamaged delivery of consignments. Further, we provide tailored packaging solutions.

PE T Rib Liner

200 - 450 Per Square Meter

1000 Square Meter (MOQ)

Pond Liners

20 - 40 Per Square Meter

100 Square Meter (MOQ)

Pond Liners help in using the cheapest source of water, rain water through water management. With their help, such water can be harvested in lakes, evaporation pond, leaching pond, ash pond canals, water storage tanks, swimming pools, raw water reservoirs and wells for use later on. The Pond Lining & Geomembrane Pond Liners on offer are manufactured making use of High Density Polyethylene (HDPE) fabric. Low Density Polyethylene Films, made of UV (UltraViolet) stabilised fabrics, are used to laminate our product.