Color Port Gauge Glass Assembly for Boiler-IBR Certified

275,000 - 1,000,000 Per piece

2 Piece (MOQ)

Glass Filter Assembly

2,350 - 3,600 Per Piece

1 Piece (MOQ)

Made from borosilicate glass with fritted glass filter base : The base design has an integral vacuum connection located above the filtrate drip to prevent contamination of the vacuum line from droplets. Anodised aluminium spring clamp. The effective filtration area is 9.6 cm Used for filtration of HPLC solvents and aqueous mobile phase solutions and buffers The scaled funnels simplify dosing and analysis

Best Deals from Glass Stirring Assembly

Sight Glass Gasket Assembly

750 Per Piece

100 Piece (MOQ)

Glass Stirrer

25,000 - 150,000 Per Set

2 Set (MOQ)

In the majority of glass plant installations,vessels find universal applications as reactors,re-boilers,receivers and seperators as well as for storage, feed or measuring. Vessels are available in spherical & cylindrical shape form 5 to 500 litre capacity. All vessels are provided with bottom outlet nozzle for which a suitable valve can be selected from the range of valves. Both spherical and cylindrical vessels can be supplied with graduation to special order. Cylindrical vessel can be supplied with glassmetal jacket also.

Glass Filter Assembly

Get Price Quote

Glass Filtration Assembly

Get Price Quote

1 Piece (MOQ)

Boiler Gauge Glass Assembly

Get Price Quote

50 Piece (MOQ)

Over Glr Glass Assemblies

60,000 - 150,000 Per Piece

1 Piece(s) (MOQ)

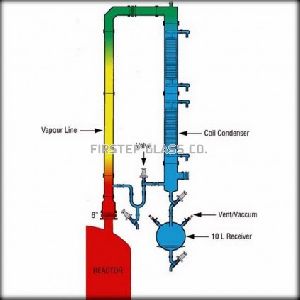

Over - GLR Glass Assemblies are used for a general purpose distillation process which is to be operated at atmospheric pressure or vacuum. Vapours from the Glass Lined Reactor (GLR) rise through the column and enter into condensers. Condensed Material then after gets either refluxed back or collected into a receiver flask. This type of unit is consisting of adaptor plate, bellow with flange, column sections, Heat Exchangers, Pipe line components, vent valves, reflux line, receiver flask and drain valve. This unit is available for GL Reactors of capacity 500Ltr. to 3000Ltr. These Glass Assemblies can be designed as per the Clients' requirements.

Glass Stirring Assembly

Get Price Quote

A variety of stirrer & stirrer drives are available to use glass vessels as agitated reaction equipment. 1. Stirrer material of construction: Glass, Stainless Steel or PTFE Lined. 2. Stirrer Design: Impeller stirrer with blades, Vortex stirrer, Propeller Stirrer & anchor Stirrer. 3. Stirring Drive: Non-flameproof or Flameproof stirrer drive, 192 RPM with Variable Frequency Drive. 4. Stirring Assembly: Stirring Assembly with bellow seal or with mechanical seal.

glass reaction distillation assembly

Get Price Quote

Glass Reactors Kilolab are multi-purpose pilot plant units having flexibility of utility. Glass Reactor/distillation unit have been standardized by incorporating all basic & essential features such as heating, stirring, condensation, fractionation, cooling etc. for multi-purpose use. Therefore, though termed Kilolab from constructional view point they actually serve as Flexi Units from utility point of view, also known as Glass Reactor and distillation unit. These glass reactor kilolab are used in educational institutions, R&D centers and industries. Distillation unit can be conveniently and quickly modified according to specific process needs due to modular construction. Borosilicate glass offers additional benefits of universal corrosion resistance, visibility and cleanliness.

Tank Mounted View Glass Assembly

27 Per Piece

1 Piece(s) (MOQ)

We are a reputed manufacturer and supplier of Tank Mounted View Glass Assembly based in Vadodara, Gujarat, India. We supply a wide range of Tank Mounted View Glass Assembly as per the customers requirements. We supply high rated units of ANSI 150#, ANSI 300# and ANSI 600# where the material certification is furnished with all the units. The maximum operating temperature of the assembly is 200° C and the maximum pressure that it can sustain is 25Kg/cm. Details : “Kabir”Manufactures Industrial Sight Glass Assembly for various mounting options such as Weld Pad type according to requirement, ANSI Flange OR Plain Pad type, Weld Neck Flange type. Other mounting options are available as per the requirement “Kabir”make Sight Glasses of Weld Pad types are designed to be welded on the Vessel or Tank. The lower weld pad flange is available in many alloys and is 150# rated standard, higher rated units are available. Cover plate flanges used in the manufacturing of our sight glasses are from ASME Section VIII acceptable materials. The lower weld pad can be provided with a cylindrical or spherical curve to match the vessel or tank, eliminating the need for special nozzles and expensive saddles. Special configurations are always available to meet customer requirements “Kabir”make Sight Glasses of ANSI Flanged type are Bolt-on units designed for attachment to ANSI flanged nozzles or vessel studding outlets. The lower flange is a standard ANSI 150# Raised Face flange. Higher rated units are also available. (300# and 600#). Material certification is furnished with all the units “Kabir” make Sight Glasses of Weld Neck Flange type are weld neck units designed to be welded on to pipe ends or into tanks or vessels. The lower flange is a standard ANSI 150# weld neck flange. Higher rated units are also available. (300# and 600#). Material certification is furnished with all the units. Features : Temperature Ratings : Maximum Operating Temperature rating is 200oC Connections : Flanged OR Socket Weld OR Butt Weld OR Weld Pad OR Weld Neck Flanged End Connection Pressure Ratings : Maximum Pressure rating is 25 Kg / Cm2 Sizes : From 15 NB to 300 NB Pad Flange : M.S, C.S. (A–105), S.S.304, S.S.316, or any other alloy. Cover Flange : M.S, C.S. (A–105), S.S.304, S.S.316, or any other alloy. Window : Toughened Borosilicate Glass. Fasteners : SS316 or SS304 or SA 193 Gr.B7 Gasket : CAF or PTFE.

Triple wall lab glass reactor assembly

Get Price Quote

Sight Glass Assembly

Get Price Quote

We are a well-known manufacturer and supplier of sight glass assembly in india. We offer sight glass assembly with excellent durability. Right from the procurement of the raw materials required for the manufacture of sight glass assembly, we consciously work on the high quality standards. Various features of the sight glass assembly make it a utility material for the clients. types double window sight glass assemblyround sight glass assemblysight glass applications used in pressure vesselsused for shock absorptionsuitable for operating with different fluids

Structural Glass Assemblies

Get Price Quote

Structural Glass Assemblies also know as Suspended Assemblies or Spider Glazing Systems have high impact visually but as they are always specific design solutions do require significant engineering consideration and must still provide a high level of weathering despite contingency in the detailing.Details : Structural glass assemblies can be large or small from a trophy cabinet to a 100% glass commercial structure The use of no mechanical fittings is possible. As structural glass assemblies do not have the benefit of movement joints or seismic receivers like a conventional aluminum framed curtain wall, special consideration must be given to building movement, live load deflections and environment loads such as wind and seismic. As these types of assemblies are often installed in areas of high density people movement, ie emergency egress pathways where human safety is paramount, it is imperative that they are engineered accordingly and that the glass specified is appropriate for overhead situations. Product Features : A wide range of fittings are available from standard spider fittings to designer fittings. Fixing detail can be tailored for individual projects including side fixed, bottom fixed or top mounted fittings to meet the requirements of small canopies through to complex glass walls. Manufactured from 316 stainless to maximise the products life and appearance and available in polished or satin finishes. Swivels are available for toughened, laminated, or double glazed units including flush fitting and surface mounted fixing options. Custom design and fabrication services are available for specific projects.

glass assembly

Get Price Quote

Distillation Assembly on Glass Lined Reactor

151,000 - 2,150,000 Per Set

1 Set (MOQ)

Glass Lined Reactors are used instead of glass reactors especially when the scale of operation is large and relatively high pressure steam is to be used as heating media. GLR is very common in API, Fine chemicals and chemical Industry Quite often assemblies like Simple Distillation Unit, Reaction Distillation Unit, and Fractional Distillation Unit etc. are installed above glass lined reactors. The basic features of these assemblies remain the same but glass shell and tube heat exchanger is preferred due to the large scale of operation Glass Assembly Set up changes with process requirements like Batch /Continuous Size of GLR Requirement of Azeotropic distillation Site constraints Process Requirements Instrumentation and Automation requirements You are requested to give following details to furnish you offer GLR Size Available total height area Operating Pressure

Glass Wiper Assembly

Get Price Quote

Our company is an experienced name, which is counted among the top Manufacturers and Suppliers of Glass Wiper Assembly from Maharashtra, India. We manufacture Glass Wiper Assembly using high-grade raw material and the latest techniques at our well-equipped production house. Due to its perfect design, it is used to clean glass surfaces in both residential and commercial sectors. Our quality controllers conduct stringent tests on Glass Wiper Assembly in order to ensure that only the defect-free ranges reaches the customers’ end. Used when manual cleaning required inside glass surface in side glass / ports

Rear Door Glass Sub Assembly

Get Price Quote

We are Offering Rear-door-glass-sub-assembl.

Bolted Glass Assemblies

Get Price Quote

This is a structural glass assembly consisting of a series of specially processed glass panes, bolted together at their corners by means of ‘spider fittings’ or ‘metal patch fittings’ along with silicone sealant at the pane-to-pane joints. The minimization of metal framing members creates an effect of transparency that forms a natural and artistic blend between the indoor space and the outdoor environment. Different methods can be used to support the dead-load of the system and to provide lateral stiffness against wind-loading. Depending on the method used, the system is sub-divided into:

Industrial Glass Assemblies

Get Price Quote

Laboratory Glassware