grain refiners

Get Price Quote

Boron is used in aluminium and its alloys as a grain refiner and to improve the conductivity by precipitating vanadium, titanium, chromium, and molybdenum. All of these are detrimental to the electrical conductivity at their usual impurity levels in commercial grade aluminium. Boron can be used alone (at levels of 0.005 to 0.1 %) as a grain refiner during solidification, Use of CERALOY-B is far more environment friendly than the conventional salt based refiners. Since no chemical reaction is involved, crucible life can be improved.

grain refiners

Get Price Quote

Best Deals from Grain Refiners

grain refiner

Get Price Quote

It is a micro structural activity in which as cast growth of fine, equiaxial grain while solidification is observed. Several factors affecting this activity are solidification time, pouring temperature, agitation during solidification, degree of metal superheat. Because it is not easy to control these factors while production, the most easy and effective way of grain refinement is deliberate addition of grain nuclei in the melt, which facilitates the homogeneous distribution of silicon grains in all kind of alloys. For such addition, combination of titanium & boron is proven to be the best nuclei. There are two types of grain refiners on the salt base compacted tablets containing titanium and & other is titanium and boron.

grain refiners

Get Price Quote

In casthouse applications, the control of grain size is essential in maintaining product consistency and quality, in reducing cost and maintaining high levels of productivity. Controlled addition of Al-TiB master alloy in aluminum releases nucleating particles that promote equiaxed, fine grained structures in cast alloys, thus redistricting formation of columnar crystals. Al-TiB grain refiner alloy improves homogeneity and allows uniform distribution of alloying elements, reduce porosity and eliminate hot tearing in cast structures, improves responsiveness to subsequent heat treatment and enhance mechanical properties and machinability in the fabrication process.

grain refiner

135 Per Kilogram

PMC Grain Refiner

Get Price Quote

grain refiners

Get Price Quote

grain refiner

Get Price Quote

100 Piece(s) (MOQ)

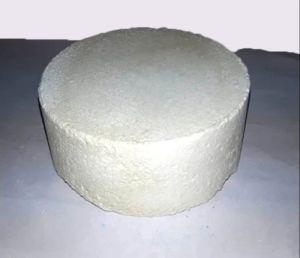

We are one of the leading Manufacturers, Exporters and Suppliers of reliable Grain Refiners in Jalandhar, Punjab (India). Made from premium aluminium, our Grain Refiners are robust and durable. We make them available in varied specifications to meet different requirements of customers. Interested buyers can get Grain Refiners from us in bulk and expect on time delivery of consignments. Sefrefiner is normally sold in capsules of 25 & 50 grams. It is a whitish Powder packed in Aluminum Sheet. Consumption : 200 grams of Sefrefiner is recommended per metric ton of melted brass to be inoculated. This equates to one 50 gram capsule for each 250 kilograms of melted brass. Alloy Requirements : Best casting results will occur with clean yellow brass ingot. Otherwise the basic Scrap Brass must be free of inclusions which are identified by a visual check of the polished surface. Good grain refinement usually occurs when the copper content is between 56 and 62 percent. Optimal grain refinement usually occurs when the copper content is 59.5 percent the aluminum content is 0.6 percent. Sefrefiner has been used to lower the casting temperatures and increase the castability and fluidity. Method Of Use :As a safety precaution, care should be taken to preheat the Sefrefiner capsules on the furnace rim, shelf, etc. so they are free of any moisture. Any adjustments to the Aluminum or Zinc content of the melt should be made prior to adding Sefrefiner. The surface of the melt should be reasonably free of slag. Sefrefiner should be added to the melt by immersing the capsules about 50 cm-75cm (approx 25 inches or 2 feet) below the liquid metal surface using a bell shaped plunger. Expected Benefits : Depending on the alloy composition, the use of Sefrefiner can result in the following casting benefits: Improved fluidity of the metal to be cast. Lower casting temperatures are possible depending on the size of the part to be cast and the type of mold to be used. Cracking tendencies of the parts to be cast are greatly reduced and most often, cracks are eliminated. The occurrence of Sinks/Misruns/Cold Shuts are greatly reduced. Lead is more uniformly distributed in the fine grain structure of alloy. Monetary Savings : Using Sefrefiner can result in the following savings: Cost of purchasing fine grained ingot gets reduced. Casting scrap is reduced. Finishing and rework costs are reduced. Energy is saved resulting from lower casting temperatures.

grain refiner

Get Price Quote

grain refiner

Get Price Quote

grain refiner, Aluminium Pressure Die Casting, water base die coat

grain refiners

Get Price Quote

grain refiners, aluminium master alloys, Foundry Fluxes, degassers

Grain Refiners for CI

Get Price Quote

Grain Refiners for CI, graphite paint

grain refiner

Get Price Quote

grain refiner, Chemical Products, cover fluxes, degassers

grain refiners

Get Price Quote

grain refiners, industrial alloys, spheroidizing alloys, flux tablets

grain refiner

Get Price Quote

grain refiner, Ladle Covering Compound, Tundish Covering Compound

grain refiners

Get Price Quote

grain refiners, Refractories, dies coats, Lubricants, degassers

grain refiners

Get Price Quote

grain refiners, Aluminum Billets, Aluminium Bracket, Aluminum hex bar

grain refiners

Get Price Quote

grain refiners, cast aluminum parts, Aluminum Billets, Aluminium Bracket

grain refiners

Get Price Quote

grain refiners, cover fluxes, die coats, Foundry Chemicals

Aluminum Grain Refiner

Get Price Quote

By our Grain Refiners and its Amendment, at the time of fluxing its produce Natural Granules of Aluminium melting of various type of raw aluminium too. For that we have apply special treatment in our Product.