Wheat Separator Machine

28,500 Per Piece

1 Piece (MOQ)

rotary separator

22,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Grain Separator

Grain Magnetic Separator

150,000 Per Piece

1 Piece (MOQ)

rotary separator

150,000 - 225,000 Per Piece

1 Piece (MOQ)

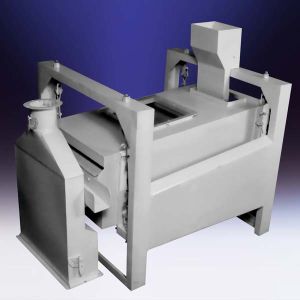

grain gravity separator

Get Price Quote

Grain Gravity Separator that we manufacture, export and supply is extensively used for sorting or separating the same size of particles in diverse specific weight. Grain Gravity Separator is used when the screen and air cleaning is not sufficient and also optimum purity of the final product is required. Our Grain Gravity Separator is a highly effective final cleaning unit that is used for any seed processing plant. It is provided with adjustable valves controls for heavy, middling and light product outlets. Also, the adjustable section include side tilt, end raise, deck speed, fan speed and air flow. Estimated Capacity on Wheat is from 1-6TPH.

Metal Separator for Food Grains

225,000 - 345,000 Per Piece

1 Piece(s) (MOQ)

TARGET GRAVITY FEED metal detection system can also be installed to inspect products such as pulps, meat slurries, jams, sauces, and dairy products. The compact design includes a rotary activated valve, inspection tube, metal detector search head, and air controls. This package can be ceiling suspended or mounted on a mobile floor stand. The control unit can be mounted either to the system frame or remotely in your plant. Specially Designed Gravity Feed Metal Detectors can also be installed to the pipeline. This system features high sensitivity, high throughput and is compact in size; it comes normally in round configurations but also available in rectangular search heads. Both the reject chute and frame are stainless steel. The inspection chute going through the metal detector is made from polypropylene, nylon, Teflon or Plastic, depending on the application. Target Gravity feed Metal Detection systems are designed to minimize system space, and product waste while insuring maximum sensitivity to all metals. The metal free product passed straight through the mechanism and diverts the ferrous, non-ferrous and stainless steel contamination from the main flow. Systems are available in Stainless Steel casing, with a selection of pipe sizes. The Diverter Valve reject system is typically used to divert contaminated product into a reject tank.

rotary separator

200,000 - 250,000 Per Piece(s)

1 Piece(s) (MOQ)

We have achieved a position as a believed manufacturer and exporter of superior quality Rotary Separator. It is used for the separation of light baggy useless particles from the removed air. Our rotary separator is an energetic mechanical sieve that is mainly used when long fibres, totals and plastics or metals scraps are present in the airflow to be treated. With suitable alterations, it can also be used as a dust gatherer.

Grain Gravity Separators

Get Price Quote

Our huge product basket commensurate to the International Quality Standards and thus, customers can rely on us for the quality. Our organization is able enough to distribute consignments on schedule due to a productive supply chain network we have. Features: Robust construction High productivity Easy to maintain

vibro grain separator

Get Price Quote

Grains come with a lot of impurities, both fine and coarse in nature. Our expert-designed vibro grain separator cleans using cleaning balls, sucking machines as well as sieves to ensure that the grains that come out at the other end are as clean as possible. We have manufactured it to high standards, and it comes with increased power efficiency.

GRAIN SEPARATOR

40,000 - 45,000 Per Bag

Food Processing: Sorting and grading food products like grains or seeds. Chemical Industry: Separating particles based on different chemical properties. Pharmaceuticals: Classifying pharmaceutical powders or granules.

Rotary Disc Separator

100 Per 1000 Piece

10 Piece(s) (MOQ)

We are leading manufacturer and exporter of rotary disc separator, slitting cutters that are also termed as saw blade. These slitting cutters are used for cutting applications in various industries, like paper, automobile, steel and fabrication, etc. Our slitting cutters are made from the finest steel, as per the set industrial standards. tips on using slitting cutters : in case of slitting cutters, since steel is to be cut by steel, the cutting quality is the prime criterion for selection of the raw material. Raw material for slitting cutters should be hardened than the metal to be cut, so that there is no deformation of the slitting cutters. The steel used for manufacturing of the slitting cutters used in slitting line should be such that it can be hardened in depth and should have sustained dimension for a longer period of its usage. Selection of raw material for slitting cutters : when selecting the material for slitting cutters, it is essential to decide which of these three main characteristics, namely hardness, tenacity and resistance to wear, should be given preference or which optimum combination of all three characteristics is desirable and possible. Description : slitting cutters are manufactured from tool steel and special alloy steel according to the application requirement. We have manufacturing facility to produce sizes up to 210 mm in diameter. We also manufacture precision cutting tools with the thickness tolerance of 0.0015 mm and flatness of .0025 mm depending on the od and thickness. This is possible with our precise lapping machines. Closer tolerances & special surface finishes are also possible. Competitive advantage : maxwell is able to deliver the same benefits as competitors but at a much lower cost and also deliver benefits that exceed those of competing products. Therefore we offer both cost and differentiation advantage. This competitive advantage has enabled maxwell to create superior value for its customers and superior profits for itself.

Rotary Grain Separator

Get Price Quote

Jogeshwari Industries is a prime Manufacturer, Exporter and Supplier of Rotary Grain Separator. Our range of Rotary Grain Separator comes with many unique features : Effective Coarse screen ensures the material to be separated falls freely via inlet onto the coarse screen, which removes coarse impurities like string, straw and stonesA durable sand sieve removes broken kernels, sand and other fine impurities. As a result the lower sieve layer consisting of cleaned grain only is passed on to the outlet. The circular movement of the sieve facilitates an increase in capacity of the sieve surfaceAn Aspiration channel built on the outlet can be supplied if there is need for aspirating the products. It will certainly improve the efficiency of separating resultsAn oscillating feeder is also attached for delivering thin, uniform stream of product over the entire width of the aspirating channel. The light particles are carried away by the aspirating air that flows through the channel while the separated and aspirated product drops via the outletProvision for regulating air velocity by adjusting the value of aspiration channel. This optimizes the aspirating effect

grain gravity separator

Get Price Quote

PLXT Roller Winnow

Get Price Quote

It takes advantage of the length difference between the whole rice and the broken rice to separate them. The machine adopts multi-cylinder combination structure. It is small in occupation, easy to change the cylinder and operation facility etc. At the same time it is has many kinds of combination mode, suit for many different demands. (BL: Cylinder in parallel CL: Cylinder in series)

rotary separator

Get Price Quote

Combined with wind, KELM125 rotary cleaning sieve runs with several tracks at the same time. It is mainly used to clean big, small and light impurities in granular stuff. In the light of different varieties, by adjusting rotary speed and weight of balance block, its amplitude is changed so as to achieve the optimum cleaning effect. Technique parameter : Initial clean-up(t/h): 25 clean-up(t/h):8 Power(kW): 0.75 Characteristics : Compact construction, steady running, good cleaning effect. Small noise, low power consumption and high output. Steady feeding flow in feeding box, stuff can be distributed even in width direction. The movement of sieve box is three tracks. It has strong adaptability for different grain with impurities.

rotary separator

Get Price Quote

Located in Punjab, India, we have earned the reputation of a trusted Manufacturer, Exporter and Supplier of Rotary Separator. Our Rotary Separators are manufactured using high-quality raw material in our well-equipped unit. They have robust construction and high durability. Used as pre cleaners to remove stick, jutes and oversize impurities from grains, seeds, rice and pulses, our Rotary Separators are high in demand among the buyers. Contact us for market-leading prices!

rotary separator

Get Price Quote

Our noteworthy entity is earnestly engaged in manufacturing and supplying a qualitative range of Rotary Separator in Punjab, India. It is widely used for separating the impurities and foreign materials from wheat, rice, pulses, etc. We manufacture it in accordance with the set industrial standards and norms. The entire range of our Rotary Separator undergoes a series of quality checks before it is delivered to the client. It is well-accredited for its great performance, sturdiness, and perfect finish.

Broken Grain Separator

Get Price Quote

We stock our product for wholesale distribution and supply as we have state-of-the-art storage facility along with the most advanced inventory management system and upgraded machines. With the complete help and support of our team members and management, we conduct strict checking on the quality of raw inputs used for manufacturing.Features : Fine finish Perfect strength Durable

rotary screen separator

Get Price Quote

1 Piece (MOQ)