Get Price Quote

Ceramic Grinding Media, Alumina Ceramic Tube, ceramic porcelain tubes

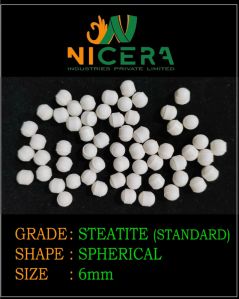

Standard Steatite Grinding Media

64 - 79 Per Kilogram

50 Kilogram (MOQ)

Best Deals from Grinding Media

High Carbon Chromium Grinding Media Scrap

47 Per Kilogram

20 Kilogram (MOQ)

High Carbon Chromium Grinding Media Scrap

Get Price Quote

12mm High Alumina Ceramic Media, STEATITE CERAMIC GRINDING MEDIA

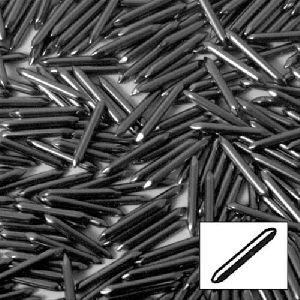

Stainless Steel Media for Burnishing

Get Price Quote

APX Stainless Steel Media - Ball, Satellite, Pin are used for high performance burnishing and polishing.Made up of high grade steel to sustain long uses and impactful applications and available in various sizes for different workpieces and processes.Highly suitable for use with our ball burnishers and vibrators for a smooth and lasting high lustre shine.

Grinding Media

Get Price Quote

Grinding media are the means used to crush or grind material (cement, mineral,..) in a mill. Grinding media sorting is performed when the ball load wears out. New grinding balls are then added or full reload is carried out to keep optimum filling degree and hence mill performance.

Hyper Steel Grinding Media

68 Per Kilogram

100 Kilogram (MOQ)

Hyper Steel Grinding Media

Get Price Quote

Our organization is instrumental in providing our clients with a superior quality range of Hyper Steel Grinding Media Balls. Fabricated using high quality raw material such as metals & alloys and advanced machinery, these products ensure durability to the end user. To cater to the variegated application requirements of engineering industries, we make these hyper grinding medial balls available in various sizes and technical specifications. These products have low abrasion.

Hyper Steel Grinding Media

Get Price Quote

Ceramic Grinding Media, Alumina Balls, Fuse Holder, electrical ceramic

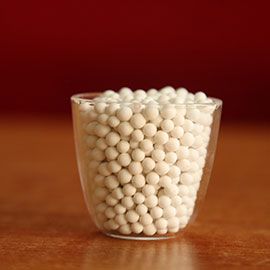

high alumina grinding media

Get Price Quote

Ceramic beads made of aluminium-silicon oxide Maheshwari® A 99.3 aluminum oxide beads have a high degree of purity with an Al2O3 content of > 99% and with secondary components of < 0.7%. These beads are ideal for use in agitator bead mills and in the wet grinding of aluminum oxide raw materials, e.g. for technical components, coatings and for high-quality paints and inks. The advantage is the availability of beads down to 0.5mm-60mm. Technical Data: High purity ≥ 99.3 % Al2O3 Specific Weight ≥ 3.8 kg/dm3 Bulk Density ≥ 2.3 kg/dm3 Roundness ≥ 0.93 (ratio width/length (xmin/xmax)) Colour: White Fields of application In the mining industry A 99.3 ceramic beads are used for the grinding of minerals and precious metals. Quality attributes The ceramic beads type A 99.3 have a dense sintered structure, a smooth surface, high roundness and high hardness.

Grinding Media

Get Price Quote

We are leading manufacturer and supplier of grinding media like high alumina 90 - 99.8%, stabilised zirconia etc.

Grinding Media

Get Price Quote

STEATITE CERAMIC GRINDING MEDIA, Polyester Epoxy Putty, Epoxy Zinc Rich Prime

ball mill grinding media

Get Price Quote

1 Piece (MOQ)

steel grinding media

Get Price Quote

We are counted among the foremost Steel Grinding Media Manufacturers based in India. Our Forged Steel Grinding Media, hardened is perfect for the applications where high chemical resistance, wear & tear are required and heat generation is crucial. Chrome Steel Grinding Media offered by us is known for hardness, high relative density and capability to mix heavy materials. Our Steel Grinding Media is also suitable for reducing the size of the particles and excellent dispersion of highly viscous fluids. The steel shots, balls and beads - ball mill media - are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and small-media mills, vertical or horizontal.

Grinding Media

200 - 6,000 Per Kilogram

1 Kilogram (MOQ)

Grinding Media

Get Price Quote

Ceramic Grinding Media, Alumina Boat, Insulation Material

Grinding Media

Get Price Quote

AVAILABLE MOCs · 3 mm—50 mm AVAILABLE SIZES

Grinding Media

Get Price Quote

Grinding Media We manufacture steel grinding media in various alloy steel compositions, shapes and sizes for diverse grinding and milling applications. This grinding media for ball mills, pulverizers and attritors is cold forged and ground. The hardened steel balls (shots, beads) are available in different hardness, as required, in both high carbon steel and chrome alloy steel. Precise heat treatment insures their resistance to flaking, chipping or spelling.Hardened steel forged grinding media is very suitable wherever high wear and chemical resistance is required. And also where generation of heat is crucial to the milling and dispersion process. The steel shots, balls and beads - ball mill media - are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and small-media mills, vertical or horizontal.Alloy steel media is particularly suitable because of its high relative density and hardness, for crushing and mixing heavy & hard materials. And also where high pressure and impact grinding or crushing methods are employed. The forged steel media balls also find advantage in reducing particle size and fine dispersion of highly viscous fluids. Our grinding media are manufactured in carbon steel and chrome alloy steel. Normally, carbon steel balls are used for common low speed grain grinding such as metal or chemical powders. For high speed ball mill grinding process such as paints, inks or resin powders, chrome alloy steel balls are usually used for extended durability.Since grinding media are always consumed in a great volume, cost and durability become the most important characteristics sought. We have been concentrating on developing cheap but durable grinding media for many years and are now able to provide the most cost saving and most durable grinding media in the market. We supply our grinding media in various finishes and shapes to save every penny. Our special heading and heat treating processes guarantee a much better durability. We will be pleased to develop custom made grinding media for any special grinding process. AdvantagesSteel grinding media finds advantage where: High wear and chemical resistance is required. Generation of heat is crucial to the milling and dispersion process. Contamination free and speedy (dry / wet) milling is important. Crushing and mixing heavy and hard materials is undertaken. High pressure and impact grinding or crushing methods are employed. Reducing particle size and fine dispersion of highly viscous fluids is required.

Grinding Media

Get Price Quote

The grinding media is manufactured by us in various specifications. The exact specification is suggested by us to the customer depending on various factors such as:Importance of wear mechanisms involved (abrasion, corrosion, impact).

Grinding Media

Get Price Quote

Grinding Media High Low Chrome Grinding Media : We can supply High chrome Low Chrome Grinding media and chrome liner for Cement , Power Mining etc industries

Grinding Media

Get Price Quote

Grinding Media

Get Price Quote

Grinding media, By utilizing quality raw material, these high chrome grinding media can be manufactured at extreme working conditions in order to fulfill the client requirements. Our High Chrome Grinding Media Suppliers offered well equipped facilities with the latest technology trends.

Manganese Steel Grinding Media

Get Price Quote

Grinding Media

Get Price Quote

Our company is premier manufacturer and supplier of Grinding Media in India. The Grinding Media offer is used to grind materials in wet & dry conditions in ball mills, attritor etc. Grinding media is widely used to grind ceramic materials like clay, quartz, feldspar, calcite etc. Grinding media is highly used at paints, inks, pharmaceuticals & other industries. Different size grinding media is used for cost effective grinding. Applications : Silica sand/Feldspar grinding, Ceramic Tile manufacturing, White Cement manufacturingNon-metallic mineral grinding, Milling of filler material, Organic material grinding for paint, ink etc.Pharmaceutical Industries Special Features : Less wear rate during its useHigh quality product with competitive pricesReliable product quality, consistency and application support to achieve best efficiency in processProvide full technical support

Grinding Media

Get Price Quote

Maximize grinding media life, improve production efficiency and lower energy consumption through expert customized product selection and grinding balls designed to last. REQUEST INFORMATION

Grinding Media

Get Price Quote

A ball mill is partly filled with steel balls (some are cylindrical shaped cylpebs) that impart a tumbling and cascading action when the mill rotates around its horizontal axis. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of high-chromium steel or manganese steel. The smaller grades are generally cylpebs.

CUMITUFF GRINDING MEDIA

Get Price Quote

CUMI supplies ceramic Grinding Media and Ball Mill Liners to the Ceramic Tile industry. Grinding media is used for particle size reduction which takes place when the material being ground is sandwiched between the media. Ball Mill Liners are supplied to protect the ball mill from wear and provide longer usable life. Over the years CUMI has developed the expertise in grinding operation and can provide guidance on media selection both sizes and proportion. In addition to experienced installation crew of CUMI can provide on-site assistance in terms of lining the ball mill. Applications Served are : Granito Tiles Floor and wall tiles Ceramic Glazes Fritz and colours Paints Food Industry Mineral Processing Zirflour Quartz Silica Feldspar Calcite CUMITUFF products from CUMI contains 90% alumina and are used in wear resistant applications. CUMITUFF Alumina grinding media has high hardness which ensures prolonged resistance to chipping and cracking Media replacement and make-up charge levels drop significantly with the use of CUMITUFF Alumina Grinding media. CUMITUFF provides zero contamination which leads to better quality mill output. The Grinding media sizes supplied by CUMI are dia 6, 8, 12, 19, 25, 30, 40, 45, 50 and 60mm. CUMITUFF cylindrical media are available for select sizes. CUMITUFF Mini Media is also available in assorted sizes of 0.5 mm to 3mm.

high alumina grinding media

Get Price Quote

High hardness ensures prolonged resistance to chipping and cracking Long term benefits are attractive as it is a cost effective alternative to conventional media Media replacement and make-up charge levels drop significantly with the use of CUMITUFF Alumina Ceramic media Media induced product contamination is practically nil when CUMITUFF is used, leading to better quality mill output