hammer mill crusher

250,000 - 500,000 Per piece

1 piece (MOQ)

The hammer mill is an essential piece of equipment used in various industries for grinding and pulverizing materials into fine particles. With its robust design and high processing capacity, it is particularly effective for handling grains, spices, chemicals, and other bulk materials. Hammer mills are renowned for their ability to reduce particle size through the impact of high-speed rotating hammers, making them a valuable asset in both manufacturing and processing environments. Versatile Grinding Capabilities Hammer mills are capable of grinding a wide range of materials, including grains, biomass, plastics, and minerals, allowing for diverse applications across various industries. High Throughput Designed for efficiency, hammer mills can process large volumes of material quickly, making them ideal for high-capacity production environments. Adjustable Particle Size The fineness of the output material can be easily adjusted by changing the screen size, enabling precise control over the grinding process to meet specific requirements.

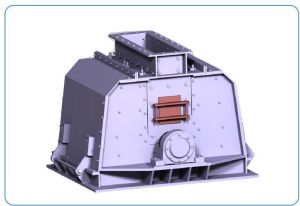

Impact Hammer Crushers

Get Price Quote

Working in assistance with a brilliant inventory management system and capacious storehouse has enabled us to entertain urgent and massive requirements of the customers. Being a prominent name in this area of operations, we, as a Supplier, bring forth qualitative array of Impact Hammer Crusher. Function Ajmani impact hammer crushers crush the material by the reciprocal effect of impact and friction between the hammer heads and dht hammer path Ratio speed and the gap between hammer heads and the hammer path determine the final grain size. Design Welded casing Side parts hydraulically swivellingh Big inspection doors Screwed lining with high-carbon steel plates Hammer path with wear-resistant baffle plates which are mechanically or hydraulically adjustable at all pivot points Dust-proof bearing of self-aligning rollers on the rotor shaft Rotor in disk-type design Resersible or single-direction design Hammer heads made of chrome alloy cast steel or composite casting Direct or V-belt drive Advantage Coal and Potash industries Steel works Gypsum and limestone plants To enable our experienced engineering staff to recommend the installation best suited to specific applications, answers to as many of the following questions as possible will result ina prompt and accurate solution to your screening requirements. Material to be screened Maximum feed dimension Approximate feed size analysis Moisture content Stickiness Bulk Density Separation sizes required Friability Abrasive Characteristics Do you intend close circuit operation Capacity desired in tons per hour

Best Deals from Hammer Crushers

Hammer Crusher

Get Price Quote

Hammer Crusher has a large feed inlet and high crushing capacity, the equipment is applicable for hard and large materials. The materials are suspended and the power consumption for crushing is I. The hammer crusher gives a great impact to the material for best results. The hammer axle is adjustable, and the hammer has a long service life. Gap between the gratings are adjustable to change grain size of the discharge, so as to meet different requirements of the customers

Mild Steel Hammer Crusher

350,000 Per Piece

5 Piece (MOQ)

Hammer Crusher

Get Price Quote

We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. Delivering the orders on time is one of our specialties for which we are highly admired by the clients. Features : Conventional prices Reliable and efficient Greater production speed Adjustable processing speed Hassle free functioning Corrosion resistant Specification : Type - Hammer Crusher Packaging Detail - Standard containers, nude package, etc.

scrap shredder hammer mill crusher

100,000 - 10,000,000 Per number

1 unit (MOQ)

4 tons per hour to 140 tons per hour output, output size: 30mm to 60 mm, can shred cast iron products also, Hammer mill shredders' feed chutes are designed with replaceable chute liners and feature state of the art, heavy duty, driven double feed roller assemblies. Hammer mill shredder rotors is specially designed with less maintenance, it does not have to be replaced, just hard faced every couple of years. The rotor powered by Siemens motor giving plenty of power for shredding process. Heavy-duty wear-resisting hammer and gear design extremely lengthen the life time and decrease the operation cost.

Hammer Crusher

Get Price Quote

Creative Hammer crusher best known and by far the most widely used crushing device employing the impact principle of bearing stone. The hammer crusher used for size reduction process such as a limestone ,glass , coal & lignite, clay , phosphate rock and fertilizer to aluminum oxide, slag’s , iron ore, coke, tungsten carbide, silica, bauxite, dolomite, grain, cement rock, and barite. Hammer crusher Advantages High Crushing ratio life of hammers and grinding blocks Easy maintenance Suitable for fine crushing High crushing efficiency Required power

Crusher Hammer

Get Price Quote

Hammer Crusher

Get Price Quote

Hammer crusher designed by Mining fits for producing 0-3MM coarse powder products. This machine adopts theories of traditional crushing machines and grinding mills. It makes up the shortage of common mills, and it is the best choice to produce coarse powder at big capacity. Pretreatment: Using the hydraulic hammer to crush the big stone into smaller one, and arrange the worker to cut through the long reinforcement to prevent damaging the belt conveyor. High production and high crushing ratio. Low power consumption, homogeneous particle size. Simple, compact and light mechanical structure. Low investment cost, easy management.

Hammer Crusher

Get Price Quote

We pride ourselves at producing durable Hammer Crushers that are strong and reliable. Our entire range of Hammer Crushers is made using top quality raw materials sourced from trusted and renowned dealers. In addition, our products are available in different sizes and grades that can be customized as per the requirement of our customers. Our company is one of the eminent Manufacturers and Suppliers of Hammer Crushers.

Hammer Crusher

Get Price Quote

Hammer crusher designed by TQMC fits for producing 0-3MM coarse powder products. This machine adopts theories of traditional crushing machines and grinding mills. It makes up the shortage of common mills, and it is the best choice to produce coarse powder at big capacity. Features High production and high crushing ratio. Low power consumption, homogeneous particle size. Simple, compact and light mechanical structure. Low investment cost, easy management.

Hammer Crusher

Get Price Quote

Hammer crusher designed by CMMAC fits for producing 0-3MM coarse powder products. This machine adopts theories of traditional crushing machines and grinding mills. It makes up the shortage of common mills, and it is the best choice to produce coarse powder at big capacity.

5E-HCB Series Hammer Crusher

Get Price Quote

5E-HCB Series Hammer Crusher is used for sample preparation of graininess material such as coal, limestone, mineral waste residue, oil shale etc. Hermetic structure improving the operation environment and reducing sample contamination. Equipped with three kinds of sieve plate. Patent for quick sieve plate replacement.

Single Stage Hammer Crusher

Get Price Quote

Single Stage Hammer Crusher that NHI China offer possesses the characteristics of high production capacity, large crushing ratio, even product size, and simple process flow. It has the double feeding rollers and single feeding roller function. Our Single Stage Hammer Crusher satisfied requirements of 5000t/d cement production line for crushing the limestones. NHI China are named among the reputed Suppliers of Single Stage Hammer Crusher in China.

Hammer Crusher

500 - 501 Per Nos

1 Nos (MOQ)

Hammer Crusher

Get Price Quote

Hammer Crusher

Get Price Quote

The company has cemented its presence among the successful Manufacturers and Suppliers of Hammer Crusher. The Crusher we make available is manufactured in compliance with set industrial norms. In order to meet the bulk and urgent requirements of the buyers, we maintain a large stock of these in our warehouse.

Swing Hammer Crusher

Get Price Quote

Swing Hammer Crushers are used daily in the mineral, ceramic and metallurgical industry among others to crush and pulverize material such as coal, plaster, salt, fire clay and other materials. Our products boast of a high crushing ratio and proven operational excellence. We also ensure that our equipment is easy to maintain and that it follows international standards of safety. The device has a controlled feeding arrangement which can be altered according to the client requirement. Details : We are a profound industry engaged in manufacturing and supplying a wide range of Swing Hammer Crusher. The offered range is manufactured using high-grade material that is sourced from reliable vendors of the market. Our experienced professionals stringently inspect these crushers on certain well-defined parameters of quality in order to rule out every possibility of defect. This range is widely used for crushing & pulverizing various material such as coal, salt, plaster, alum, brick, fire clay, clay, george & other minerals. Comprise of: Controlled feeding arrangement Hammers that are fitted with spindle and rotor Breaker plate Screen bars having suitable gap opening Features: High crushing ratio Operational excellence Easy maintenance Durable standards Anti-corrosive Application areas: Ceramic industry Mineral handling Food and beverages Chemical industry Petrochemical sector Metallurgical areas

Hammer Crusher

50,000 Per Piece

Hammer Crusher

Get Price Quote

Hammer crusher ( screen type equipment ) is employed to disintegrate almost everything, from paper products to limestone and spices. Traditional disintegrators are technologically replaced by these modern and highly versatile machines, having total flexibility. Combination of different hammer styles, liner plates, sieve inserts and wear resistance technology offer almost unlimited possibilities of crushing lumpy, bulky, irregularly shaped, hard & fibrous materials, into coarse to medium fine powders. Materials enter at periphery of swing hammers undergoing size reduction along liner plates before discharging through perforated sieve at bottom. Replaceable bar type grate is available for specific applications.