heat treatment furnace

Get Price Quote

1 Piece (MOQ)

Details: Heat Treatment Furnaces for Various application Annealing , Normalising Hardening , Solution Treatment Heating , Forge Heating , Tempering Aluminum Solutionising , Stress Relieving , Ductile Iron Full Annealing Strong rigid construction , Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimizing heat losses Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability With as per the Required AUTOMATION. Applications Annealing Normalising Hardening Solution Treatment Heating Forge Heating Tempering Aluminum Solutionising Stress Relieving Ductile Iron Full Annealing. Auto cycle control Ramp, Soak, Cool ..... 8 Steps Profile 10, 20 Profile Memory Multi Input Multi Output (MIMO) PID Controlling Action. Micro processor based programable controller. one burner, one thermocouple forms one pair as zone, thus multi zone control Digital display for time temprature graph online with USB pendrive for data storage, Wired lan PC connectivity for real time graph printing Firing High Velocity Short Flame Burner Direct On/Off pulse firing effect. Smokeless perfect combustion The furnaces are calibrated for uniformity as per API 6A Standard ( The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.) Mechanization Trolley - movement by geared motor with brake. Door - movement by geared motor with brake, counter weighed, Door Lock Unlock - innovative,Pneumatically operated instant latching unlatching for perfect sealing Construction Strong rigid construction Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimising heat losses. Insulation High temperature high density ceramic fibre modular lining. Self supporting U-fold door lining. Recuperator All fuel fired furnaces are equiped with recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 150 degree C in combustion air 7.5% heat is recovered. PLC control Large furnaces handle high value materials, it is essential to install PLC for opration to avoid manual errors. PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visualy & through SCADA PLC keeps event history for the record Control Panel Aesthetically powder coated control panel. Electrical switch gears for drives, burners. Status indication and control. Burner sequence controller and flame failure device. Programmable startup, burner, temperature controlling system. Calibrations Thermal survey as per API 6A Standard. All measuring instruments calibrated to national traceability

heat treatment furnace

45,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

Our products are subjected to the payment terms & conditions of our company. Patrons are provided with the terms & conditions, and can make purchases with a payment method best suited for them. We have established a state-of-the-art warehouse facility and equipped it with the latest inventory control system. Thus, we can take care of seasonal supply, wholesale supply, and quick supply among others. Our Heat Treatment Furnace evenly transfers the heat to provide great results.

Best Deals from Heat Treatment Furnaces

heat treatment furnace

100,000 Per Piece

1 Piece (MOQ)

Continuous Heat Treatment Furnace

Get Price Quote

We are engaged in manufacturing Continuous Heat Treatment Furnace that provides strength to products through heat processing. The Continuous Heat Treatment Furnace range is available in resistance heated and gas/oil fired versions. The Continuous Heat Treatment Furnace range offered by us can accommodate a variety of materials and treatment goals through the use of optimized settings for heating and cooling temperatures, wait times, heating and cooling speeds, and ambient conditions. Our Continuous Heat Treatment Furnace comes with attendant equipment such as controllers, ambient gas generators, and cooling units.

Heat Treatment Furnaces

50,000 - 2,500,000 Per piece

1 Piece (MOQ)

Heat Treatment Furnaces

Get Price Quote

1 Piece (MOQ)

Heat Treatment Furnaces

Get Price Quote

We manufacture and supply furnaces for heat treatment purposes with programmble thyristor control panel,lab furnaces,high temperature furnaces,muffle furnaces with thyristor scr panel ,automatic ramp and soak feature and maintaining heating rate cycle,programmer p.i.d controller muffle furnace,hot tensile testing furnace with double zone independent control,spectro sample polishing machine,argon purifier furnaces,heating elements,thermocoples,carbon sulfur apparatus and quality lab metallurgical testing equipment,lab ovens,air circulation ovens and lab testing equipment etc kindly contact us for any above related enquiry we look forward to serve you with our best quality products and serviceswe can,supply heating elements,thermocouples, thyristorise energy saving panels,retort etc.

Heat Treatment Furnaces

Get Price Quote

We are offering heat treatment furnaces. the wide range of heat treatment furnaces manufactured and supplied by us are applied in fields like annealing, forging, hardening, preheating, quenching, homogenizing, carburizing, carbonitriding, stress relief, tempering, pelletizing etc. Heat sources offered by us in these machines are fuel based and electric heating elements. Max temp:1600'c

Vacuum Heat Treatment Furnace

Get Price Quote

heat treatment furnace

1,000,000 Per Set

1 Set(s) (MOQ)

We manufacture all types of heat treatment furnaces like continuous, batch type, pit type, bell type, sheaker hearth, muffle type etc. In order to keep transparency in dealings, we offer our clients an invoice including the details of the products, quantities and price on which both the parties agreed for the payment. Moreover, our payment procedure is safe. If you are looking for purchasing qualitative and cost efficient heat treatment furnace, contact us today!

Heat Treatment Furnaces

50,000 Per Set

Latest, Strong, Sturdy, PLC/PC Controlled Heating Quenching Technology by Dhanaprakash MN Steel Hardening, SS Solution treatment, Forging, Quenching, Tempering & Normalising. Also available for PWHT (Post Weld Heat Treatment) (N+Q+T & Q+T) Applications Annealing Normalising Hardening Solution Treatment Heating Forge Heating Tempering Aluminium Solutionising Stress Relieving Ductile Iron Full Annealing ADI (Austempered Ductile Iron). Auto cycle control Ramp, Soak, Cool .... 8 Steps Profile 10, 20 Profile Memory Multi Input Multi Output (MIMO) PID Controlling Action. PLC Based programmable controller. One burner, one thermocouple forms one pair as zone, thus multi zone control Digital display for time temperature graph online with USB pen drive for data storage, Wired LAN PC connectivity for real time graph printing Complete Report generation by data logging & Processing (SCADA).

heat treatments

Get Price Quote

Horizontal Vacuum Heat treatment Furnace

Get Price Quote

The Advanced Horizontal Vacuum Heat treatment Furnace used for Hardening, Annealing and Brazing applications. The operating temperature is 1750 degree C. And the charge weight is up to 500 Kg. This furnace has the coolig facilitity of forced cooling by canned motor, blower and heat exchanger.

Bogie Hearth Heat Treatment Furnace

Get Price Quote

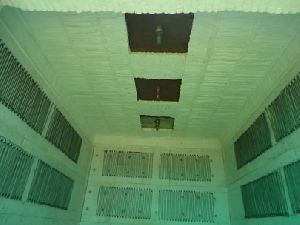

These are high temperature furnaces that are exclusively made according to the need of the client. International bogie electric technology is employed and advanced high temperature is used in the system. Our company has worked on this furnace keeping in view the need of the market and international level competition. Mass production on production line will be started as soon as more orders are received. The bogie hearth heat treatment furnace of our company is highly energy efficient and has been used for products such as high manganese, roller, ductile iron, ball, high chromium, liner quenching and crushed hammer heads. The lining material of the furnace is made up of very light steal. Steal head and lining makes the furnace super energy saving. It has insulating refractory brick as well. Good quality furnace bull bricks are used for furnace mouth. Latest technology is employed along with labyrinth technologies. Along with this, automatically seal agencies are also employed for the reduction of heat loss and increased temperature efficiency. Appropriate adjustments according to the needs of the user can be made as the equipment has electricity magnetic breaks. Multiple temperature control system is installed to improve the temperature uniformity inside the furnace. This is assured with the wall layout heating components modification. High power and high temperature bogie hearth resistance furnace has multiple temperature control counters. Furnace door’s bogie operations are also carried out easily. For the control system and temperature fluctuation maintenance most advanced procedure have been used with advances technology curve in microcomputers. This aids in ruling out even minor errors when operation is done.

heat treatment furnace

Get Price Quote

heat treatment furnace

Get Price Quote

We design and manufacture Heat Treatment Furnace for Ferrous and non-ferrous metals, ovens and driers for chemicals, and other specific processes as per customer's specifications. We provide gas fired Heat Treatment Furnaces that are convenient to use and cost effective in operation. Our Heat Treatment Furnaces are energy efficient, reliable and user friendly with minimum maintenance. We also help our customers to find out appropriate and total solutions to their requirement. We also provide prompt service and spares for minimum downtime. HT furnaces and driers can be heated by various heating media like : Electricity Gas or other fuels We offer a wide variety of Heat Treatment Furnaces that can be listed as follows : Our Range Roller hearth furnace Shaker hearth furnace Rotary furnace Bogie hearth furnace Chamber furnace Box furnace bell Type furnace Walking Beam Furnace Pot Type Furnace Uses Of Heat Treatment Furnaces Hardening Stress relieving Annealing Drying and curing Tempering Normalizing Stress relieving Bright annealing in special atmospheres

High Temperature Heat Treatment Furnace

Get Price Quote

Our company is one of the eminent Manufacturers, Exporters and Suppliers of a wide range of High Temperature Heat Treatment Furnace. Made using the latest technologies, our entire range of High Temperature Heat Treatment Furnace is high performance, optimally functioning, reliable and durable. Since, we offer them in varied specifications and offer customized solutions; our High Temperature Heat Treatment Furnaces are the preferred choice of many. Constructions : Most useful where high temperature curing is required with maximum temperature up to 1500°C and working temperature range up to 1450°C. Fitted with Microprocessor Based Digital Temperature Indicator-cum-controller. Silicon-carbide heating elements are fitted for uniform temperature inside the chamber. Body mounted on a heavy M.S. frame covered with CRC Sheet duly powder coated. Fitted with chamber made of Cumilag tiles exhibit unique combination of chemical, mechanical stability and insulating properties. These are suitable for applications at high service temperatures. Bubble alumina range of insulating refractories are of light weight, have good load bearing capacity, and low heat capacity. These can be directly exposed to flame, and combustion products. Features : Very high refractoriness, structural strength Low thermal conductivity, shrinkage and creep. High resistance to reducing atmosphere and Uniform pore size. Distribution and Control through a phase angle control Thyriostorised Power Drive with Soft Start and a multitap solid state step down transformer.

heat treatment furnace

Get Price Quote

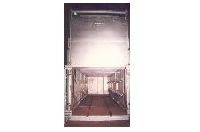

Knackwell manufactures Heat Treatment Furnaces in either electric or gas or Oil fired heating systems. The design of the heating systems provide for shielding of the loads from the detrimental effects of direct radiant heat or flame impingement while promoting efficient uniform heating of the loads. Electric Heating Systems : Electric Heat Treatment Furnaces employ various styles of resistance type electric heaters to maintain the integrity of the furnace atmosphere and thermal efficiencies. Heaters can be supplied as either standard open resistance wire/strip type. Thyristor power controllers with control panel door mounted diagnostics displays are standard for Knackwell Heat Treatment Furnaces, with optional PLC and PC systems integration available. Heating systems are factory pre wiredto meet NFPA standards where applicable, and all equipment is factory tested prior to shipment. Gas Firing Systems : Gas fired furnaces employ either direct gas firing or indirect style gas firing burners to maintain the integrity of the furnace atmosphere. Following burner types can be supplied by Knackwell Details : Fuel - LPG or Natural Gas Modulating Two Stage ON/OFF Capacity Range from 55,000 Kcal to 33,00,000 Kcal Solid state flame supervision systems with panel door mounted diagnostics displays are standard for Knackwell Heat Treatment Furnaces, with optional PLC and PC systems integration available. Combustions systems are factory prepiped to meet NFPA standards where applicable, and all equipment is factory tested prior to shipment. Thermal Recirculation Systems : Knackwell Heat Treatment Furnaces utilize Stainless steel construction fans for recirculation of the furnace atmospheres, promoting close tolerance temperature uniformities. Recirculation fans are located within a stainless steel plenum positioned in the top of the furnace heating chamber, integrated with the gas firing or electric heating system, to eliminate potential of direct heating of the workloads. Lateral sidewall ductwork is employed for introduction of the furnace atmosphere into the workzone beneath the workload, with recirculation and redistribution through the fan plenum inlet. Water jacketed Coldcar Type Furnace Design : Knackwell Heat Treatment furnaces employ our "Cold Car" loading hearth design which only requires heating of the work load and loading hearth, rather than the entire structural car. The "Cold Car" is designed with sand seals positively locating the car to the furnace structure minimizing heat loss while maintaining atmosphere integrity. Custom Designed and Engineered : Our in-house engineering and manufacturing allows Knackwell to custom design furnaces and systems to a customer’s process and specification requirements, rather than attempting to provide to you standard pre-design equipment, as some of our competitors would attempt to do. Follow-up technical services are available for all Knackwell thermal process systems. Our Engineered Thermal Solutions will allow for flexibility in your manufacturing productivity with following advantages : Total system packaged in common frame including power and control components Heavy Gauge Welded and Reinforced Steel Frame Designed insulation selection based on the design and process of the furnace. Water-Jacketed Cooling Section Master – Slave control system to temperature uniformity within the furnace. Minimum Power/Fuel Consumption for the operation of the Furnace. Programmable Set Point Temperature Controller Phase Angle-Fire Thyristor Power Controller Independent Over-temperature Instrumentation Type “K” Thermocouples

Vacuum Heat Treatment Furnace

200,000 Per Piece

Non-Ferrous Heat Treatment Furnaces

Get Price Quote

These furnaces are solution treatment furnaces for non-ferrous metals such as Aluminium copper for the temperature of 600º C. These furnaces are technically designed for uniformity with a circulation fan inside the heating chamber.Capacity as per client requirement.

heat treatment furnace

325,000 Per Piece

1 Piece (MOQ)

CONTINUOUS HEAT TREATMENT FURNACES

Get Price Quote

Ageing furnaces are for ageing of aluminum extrusions, Conductors, aluminum casting, etc. with very close temperature tolerances, Single or double draw out trolleys with vertical opening doors, The furnaces can be operated semi automatically, controlled by PLC systems with HMI that allow precise control of the process, The heater battery is designed with low watt density heaters, for long, trouble free life and are modular, making them easy to maintain, Contactor type or thyristorised power supply for maximum efficiency and higher temperature accuracy.

Heat Treatment Furnaces

Get Price Quote

We are a trusted name, engrossed in manufacturing, supplying & exporting of Heat Treatment Furnaces from Maharashtra, India. Our Roller Hearth Furnaces are designed and manufactured in accordance with industry standards and market demands. Our Mesh Belt Furnaces have attracted various national as well as international clients due to their unmatched quality and unsurpassable performance. One can get them at reasonable prices, from us. More about Heat Treatment FurnacesHeat Treatment Furnace provides strength to products through heat processing. The Heat Treatment Furnace range is available in resistance heated and gas/oil fired versions. The Heat Treatment Furnace range offered by us can accommodate a variety of materials and treatment goals through the use of optimized settings for heating and cooling temperatures, wait times, heating and cooling speeds, and ambient conditions. Our Heat Treatment Furnace comes with automatic equipment such as Temperature Controllers, PLC, Thyristor, SCADA etc. The use of quality raw materials in the manufacturing makes the furnaces durable, strong and resistant to adverse conditions. We are well reputed for the consistency and precision of the temperature in the entire heating zone of such furnace. Features : Transfer Mechanism : Roller hearth or Conveyor Chain Semi-continuous, indexing type design Electrically or Gas Heated Re-circulation Fans to ensure temperature uniformity better than +/- 5 degree C Agitators in Quench tank ensure uniform quenching Pneumatically Operated Dampers for Sand Removal Quench Delay : 15-20 seconds.c Automatic Sand Removal from quench tank ,Optional Air Quench Facility ,PLC controlled Capacity : 100 kgs / hour to 2000 kgs / hour.

heat treatment furnace

72,800 - 750,000 Per Piece

spring produced on automatic machine gives dimensional accuracy. while forming and coiling springs, wire gets stress, which affect the spring function as well as life. for high accuracy stress releaving digitally controlled furnace are required. by keeping in mind we designed and developed digital control furnace for exact customer need. up to 5 kw/ 9 kw furnace designed in box type. for more production need conveyortempering furnaces are used. temperature and timer are digitally controlled by special electrical control panel. specificationsmodels df -5df - 9dcf -25 wattage (kw) 5 9 25 type tray (trolly) tray(trolly) conveyor temperature (5000 c) digital digital digital timer digital digital digital isulation cerwool & glasswool cerwool glasswool cerwool, glasswool & air curton accuracy better than +- 30 c better than +- 30 c better than +- 3 0c

Continuous Heat Treating Furnace Plate

Get Price Quote

We are backed by modern transit facilities and thus while located in Aurangabad(India), we are able to reach any destination easily. We have a capacious warehouse facility that assists us completely in making stock and furnishing varied requirements of the clients. Also, our facility is equipped with modern storage amenities.

heat treatment furnace

Get Price Quote

We guarantee our products are subjected to stringent quality policies to meet industry standards. We have different payment options to choose from as per the convenience of the clients. In the type of operation processed online, the procedure depends on the gateway or processor model; both of them ensure complete security.

industrial heat treatment furnaces

200,000 Per unit

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces for Melting glass and precious metals. These are also used for various R & D purposes. The energy efficient designing using latest technology available around the globe helps in lower running and maintenance cost which we deliver to our customer at no extra cost which furthers help them to increase their production resulting in higher profits.

Heat Treatment Furnaces

Get Price Quote

we pleased to get this opportunities to introduce our firm specialized for undertaking refractory installation work. We involve in this field since long back time and executed several new projects as well as rebuild/ repairing work in india and abroad with excellent quality of work performance within a stipulated time frame. Our company is registered and developed with all infrastructures i.e. Equipments, tools-tackles, organized workmen team. So, we are capable to undertake any quantum of related work in any industry and for your kind information, we have our own epf code, esic code no, gst, pan and manpower holding with valid passport. So, we can comply all statutory liabilities and fulfill all obligations. Assuring you that we shall always be at the best service in future and all your enquiries will receive our best attention, we request you for your kind consideration for us.

heat treatment furnace

Get Price Quote

Reckoned for robust structure and high performance, our Heat Treatment Furnace is of unmatched quality. The Furnace is compact-in-design and is completely safe. Buyers can get a wide range of Heat Treatment Furnace from us at the market leading prices. Buyers can rely on to supply Heat Treatment Furnace in bulk and maintain year-round availability of the same. In order to acquire the best, feel free to contact us!