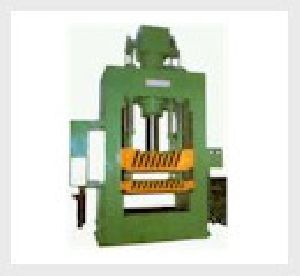

high speed hydraulic presses

424,653 Per unit

Hydraulic High Speed Press

Get Price Quote

1 Piece (MOQ)

Best Deals from High Speed Press

High Speed Press Tooling

Get Price Quote

UMS provides insights and resources on high-speed press tooling, a manufacturing process that uses specialized presses to rapidly produce high volumes of parts. We offer guidance on everything from design considerations to troubleshooting techniques, helping engineers and manufacturers optimize their tooling processes for high-speed production. Achievement: Developed new, efficient high-speed press tooling designs. High customer satisfaction by delivering high-quality, high-volume parts. Implemented innovative process improvements to optimize performance and reduce downtime. Provided training and education resulting in increased productivity and improved product quality. Industry awards or recognition for innovation, quality, or customer service.

High Speed Tablet Press

Get Price Quote

The machine is double rotary tablet press with inbuilt pre-compression. All machine controls are adjustable from outside of the machine. The pre-compression is having a fix tonnage of 2 tons. The pressure roller is made of special material---- EN 31 forged steel and is mounted on the bearings. Pressure rollers have a unique sliding mechanism which makes the machine easily accessible during cleaning and maintenance. The pressure loading is designed in such a manner to achieve desired thickness of the tablet and can be controlled by knobs on the side of the machine. Overload release is already provided in the machine to safeguard against any overload in hydraulics. The machine is fitted with force feeders having variable frequency drive and force feeders are designed with three paddles for the optimum performance over the wide range of materials and tableting speeds. The drive of force feeders and turret is synchronized for better performance. The force feeder is easy to assemble/ disassemble. The material flow to the force feeder is also controlled by lockable butterfly valve. Salient Features: ELNP Turret and Upper cam tracks Force feeder (Aluminium alloy- hard anodized) Outside tablet parameter controls for tablet thickness and weight Unique press roll with sliding mechanism MHCOS:- Manual hydraulic compression overload system Auto lubrication Machine operation with Touch type HMI (Through PLC) Features: Top guards in acrylic with dust free sealing Pressure roller on bearing Hopper level sensor Turret with anti-corrosive ELNP - electroless Nickel plating Audio visual safety alarm system with logs for emergency and records Sliding press rolls for easy access to compression area Solid pillar and frame construction with ring and pinion arrangement Two way discharge chute for start/shut down rejection Optional Features Three piece turrets 15 H.P. Motor for special application Anti Vibration mount CE certification. 21 CFR part 11 compliance (SF) Bi Layer with force feeder Bi layer attachment with pneumatic sampling. Bi layer sampling rejection (Force Display) IQ, OQ, DQ documents

Ungeared High Speed Press

Get Price Quote

C-frame high speed press machine, also known as ungeared high speed press machine, is a new generation of high performance press,.

high speed press

20,000 Per Piece

High Speed C Type Hydraulic press

Get Price Quote

Features : The C-Type High Speed Press is one of the new generation of plate process and developed by DISHAA. C-frame design for large operating spaces – suitable for automatic operations forming, punching, bending, straightening and multi-press assemblies to form automatic production line. Totally European design, monoblock, welded steel frame rigid to deflection moment and high tensile with ST44 A1 material. Fully enclosed drive, easily accessible for maintenance, eliminates, exposed over hanging parts, slide and bolster tables with T-slots. The C-frame hydraulic press uses a variable flow piston pump – offers high pressure resistance, high velocity, durability and low noise. Main cylinder is specially designed for high velocity, motor uses less power, high ascending and descending speed, increased efficiency. Hydraulic pipe system uses integrated circuits – manifold block fits inside the press to reduce piping and oil leaks, easy to maintain, simple and safe. Hydraulic system is from Bosch, Germany. Protective fence and the safety interlock to ensure the operation safety. The hydraulic press has a movable single-hand pedal switch, easy to operate. Front side covers with safety switches, back light safety guards (Category-4), foot pedal conforming to CE regulation. Guiding device: the metal fabrication equipment adopts four cylindrical location guiding to make sure of the steady precision, and it’s easy to test and maintain. Presses operated with automatic one cycle design; two hand push button design for simple and safe operation. Presses which could realize three-operation mode: adjustment, manual and semi-automatic. This gap press uses PLC control, is flexible and safe. djustable proximity switches allows stroke adjustments in seconds. All our electrical, hydraulic and mechanical parts are standard in the industry and available throughout North America and Europe. The metalworking machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA. Dual control you can select to use: a) Moveable pedestal height for comfort and ease of operation c/w dual electric palm buttons & extra emergency stop. b) movable single-hand pedal switch. Optional touch screen terminals offer. a) Data storage of mould(s) and manufacturing conditions. b) Reduced mould replacement time and calibration, fabrication requirements. c) Programmable memory for working conditions, displays pressure, stroke, spend data, etc; one cycle process sequence.

high speed press

Get Price Quote

High speed press High performance, High production, Reliability, Economy & Safety insured, Welded steel construction with maximum rigidity&lowest deflection. Fabricated steel slide running in extra-long guides to ensure perfect alignment. Combination clutch and brake with inter-looking of functionsand dual solenoid valve to ensure "Fail-Safe" operations. Variable speed drive for wide range and quick selections of speed. Motorised lubrication System,cenrally conrolled and monitored,so that in case of any fault in the system the machine stops immediately. Well-Designed control station for easy operations. stroke counter,slide adjustment indicator provided on machine. Hydraulic overload safety (Optional). Flywheel & motor guards. Bearing temperature sensor is an optional feature. This prevents damage to major berings by stopping machine if bearing temperature exceeds preset values.

High Speed Rotary Tablet Press

Get Price Quote

CGMP Machine Most Suitable for large scale production Force feeder attachment is a standard features for higher weight consistency of Tablets For smooth running of machine, internal helical gear ring and pinion drive are provided All parameter of table can be control outside of machine Continuous lubrication system available Front side, Separate Electrical Panel available Lower Punch seals in Turret Upper punch penetration Round Hopper provided with butter fly valve Upper & lower pressure rolls fitted with ball bearings Lower guard has Hydraulic gauge

600 Ton High Speed Deep Drawing Press

Get Price Quote

We offer heavy duty frame type deep draw press, hydraulic deep drawing presses, which are widely used in different industries to manufacture deep drawing components. These are heavy duty, high performance, pillar type hydraulic press for manufacturing deep drawing press components. Impeccably equipped with most advanced hydraulic & electronic (PLC) control. They are designed for high off center loads with heavy RAM force. Accurate slide guiding with full stroke length is helpful to provide the better accuracy & effective performance of the presses. Deep draw press is perfect for deep drawing automobile sheet metal components, oil tanks, stainless steel kitchen sinks, mudguards etc. Note Deep Draw Press is available upto 4000 Ton Capacity as per the customer's specific requirements Deep Drawing Press will be available with Pillar / Gate / Frame Type High Capacity press will be prefered in column type. The Press will be manufactured as per the customer requirement. Click here to Request a Quotation for Hydraulic Press over & above the specified capacity.

Sew Hsd Series High Speed Press

Get Price Quote

1 Piece(s) (MOQ)

We are offering high speed precision power press from 125 & 200 tonne salient features: 1. Rigid and robust straight side frame design makes it angular deflection free and increase accuracy for progressive die. 2. Zero angle deflection of frame will reduce cost of tooling and maintenance for long life. Product range: hsd series 3. Pneumatically operated single disc combine clutch and brake to ensure minimum response time and enhance operation safety and noiseless operation. 4. 8 points extra long gibs fitted with sintered bronze linings gives long life accuracy 5. Turcite-b linear motion in slides for friction and vibration free smooth running and reduce worn out of slides. 6. Bearing temperature sensor will alarm for over heat and stop the machine. 7. Hardened and ground gear will give smooth and silent operation. 8. Built in hydraulic over load safety will gives safety against overload situation and stop the machine immediately 9. Dual solenoid valve enhance safety against failure of single valve. 10. Motorised slide adjustment reduce labor and increase yield. 11. Digital die height indicator increase accuracy of operation 12. Easy to operate plc panel with hmi in front panel for displays of faults, batch counter, preset counter, time totalize, lubrication counter, anti repeat timer. 13. Plunger guiding system allow precise adjustment of slide running clearance and enhance parallelism and squareness of travel accuracy and tooling life 14. Wide slide and bolster area

high speed oil hydraulic presses

Get Price Quote

REDSON manufactures various types, models and sizes of Hydraulic Presses. Every press is designed, developed & manufactured as per customers specifications up to 2500 tonnes.

High Speed Precision Power Presses

Get Price Quote

This is a straight sided, single action press having steel plate fabricated construction duly stress relieved, with 8 point gibbling of slide, fitted with pneumatically operated combined single disc friction clutch and brake, motorized automatic lubrication with re circulation arrangement and manual slide adjustment. It features inter-locking of functions and dual solenoid valve to ensure "FAIL SAFE" operations. The variable speed drive for wide range and quick selection of speed together with above features makes this press extremely productive, reliable and safe. The press is supplied complete with electricals, comprising electric motor, control panel, die area light, preset production counter, anti-jam releasing device, electro-pneumatic safety controls. It is available in 25, 40, 63, 100 and 160 Tons capacity. Please ask for further details on High Speed Roll Feeder, Straightner, and Decoiler available as optional extra equipment.

high speed stamping presses

Get Price Quote

We are offering high speed stamping presses.

high speed press

Get Price Quote

The 4250M is a compact high-speed four color Dry Offset press from the family of presses manufactured by Hyden for the decoration of disposable plastics cups and containers used in the food and dairy industry. Attractive decoration of Injection molded or Thermoformed containers in four colors is offered by this press. Continuous high-speed runs in a compact work area at low energy inputs gives this press an edge over other models making it suitable to cater to very large printing volumesThe 4250M is a semi-automatic press that makes it easy to operate and keeps it low on electrical power and floor area. This press has the proven Magicure UV-OMC curing system that cures printed containers on their mandrels prior to ejection. A number of optional features allows this press to be configured for enhanced operational features and requirements. The Signature Series option for this press gives it full automation from stack in-feed to re-stacking of printed containers.

high speed press

Get Price Quote

Emco Pressmaster Pvt. Ltd. is counted as a reliable Manufacturer, Exporter, and Supplier of High Speed Press Machine (PMX Series). The PMX series High Speed Press Machine is known for its unique 'H' Frame straight sided double column. The machines features four piece tie rod construction, thus can efficiently handle upto 315 ton load for high repeatability of BDC. Salient Features Crank shaft in Antifriction Bearings. 8 Point slide in antifrication Bearings. Plunger guided Ram. 2 Point Hydraulic Overload protection. Dynamic Balancer in Antification Bearings. Hydraulic Thread Counter locking. Tpm compliant Electrical control. 16 digital cams. High repeatability of BDC for precision blanking. Power takeoff Shaft for Mechanical feeder drive. NC Feeder Compatible. Dry clutch. Reduced stopping Angle. Re-circulating flood lubrication. Temperature Monitoring of Bearings with High cut-off.

High Speed Power Press

180,000 Per Piece

1 Piece (MOQ)

high speed press

Get Price Quote

Single point Suspension Non-Inclinable Single Action Press, having Fully Steel Fabricated Construction Duly Stress Relieved with 8 point Gibbing of Slide, Fitted with Pneumatically Operated Combined Single Disc. Friction Clutch and Brake. Standard Equipments: Optional Accessories: 1. Automatic Grease Lubrication.2. Air Counter Balancers.3. Programmble Limit Switches.4. Variable Frequency Drive.5. Stroke Counter. 1. Pneumatic Die Cushion.2. Motorized Slide Adjustment.3. Hydraulic Overload Safety.4. Photo Safety Guards.5. Die Height Indicator.6. Misfeed Detector Socket.7. Quick Die Change System.8. Die Area Lighting.9. Air Tool Socket.

High Speed Intermittent offset press

Get Price Quote

TR2 has been continuing to develop as up to date UV offset printing machine. The wet type has been appeared after dry type to pursue further high quality and stability of printing. Concentrated automatic control is equipped to improve efficiency of operation. TR2 will expand the possibility of Label Industry.

Giga Press GMP Model High Speed

Get Price Quote