high temperature wire

5 Per Meter

1000 Meter (MOQ)

High Temperature Wires

Get Price Quote

The manufacturing unit utilizes latest technology machineries and good quality resources to produce these rubber cables. These cables are scrutinized before exporting for ensuring superiority by trained individuals.

Best Deals from High Temperature Wires

High Temperature Automotive Wires

Get Price Quote

HTAW™ automotive wires for continuous use at operating temperatures of up to -40ºC to +150°C (Class D), + 200ºC (Class F) and +250ºC (Class H), confirm first mover status in the development of forward-looking product technology. This new generation of automotive wires are suitable for vehicles with hybrid power trains and for fuel cell wiring applications. -40ºC to +150°C (Class D) -40ºC to + 200ºC (Class F) -40ºC to +250ºC (Class H) ZZZZ Conductor : Soft annealed electrolytic copper, Bare or Tinned or Silvered. Insulation : High Temperature Fluro Polymer, with properties similar to ISO6722 ClassD

PTFE High Temperature Wires

Get Price Quote

High temperature wire,is stocked since many internal and external wiring applications are used in environments. We carry high temperature wire in a wide variety of materials and configurations to suit every application.

High Temperature Wires

Get Price Quote

Equipment or hook-up wires are small insulated wires which are used extensively in all types of electrical apparatus. Originally developed for use in aircraft, PTFE equipment wires, due to their performance and reliability are now widely used throughout the industry, where environmental condition preclude the use of ordinary PVC insulated wires. The small size of PTFE insulated equipment wire coupled with high voltage rating saves valuable weight and space in miniaturization and the high temperature limits of PTFE enables soldered connections to be made without damaging adjacent wires. We manufacturer PTFE insulated silver plated copper wire as per American Military Specification W-16878. Our PTFE wires are as per JSS specifications 51034. These PTE insulated hook-up wires are manufactured in different sizes and different voltages. We manufacture these wires according to American Wire gauge system. Normal size of wires varies from AWG 32 to AWG 12 in single strand as well as multistrand. Insulation thickness of these wire depend upon voltage ratings. Generally three different voltage codes for each type of voltage ratings. We can also supply the material for higher voltage for specific requirements. Chart sowing diameter of base conductor and diameter and diameter of insulated wires having different voltage rating are given SPECIFICATION PTFE INSULATED SPECIAL EQUIPMENT WIRES Please refer to table for commonly available sizes. Within the normal range, larger number of strands are available to improve flexibility and flex-life; 19 strands up to AWG 30, 37 strands up to AWG 20 and 60 strands for AWG 9, 10, 11, 12 and 13. In the two larger sizes AWG 6 and 8, compact 61 strands true concentric constructions (compared to Rope lay 19 x 7) are about 15% lower in OD, weight and cost, although slightly stiffer. We offer finer sizes, having thin-wall PTFE insulation, highly flexible (with flex-life) constructions using Silver Plated High Strength Copper Alloy (SPHSCA). Sizes as small as AWG 37/7/45 (0.43 mm). Even such fine sizes are 100% tested. For Wire-Wrap wire, advantages of PTFE insulation are now available in single strand size up to AWG 36 (OD 0.43 mm), and multi-strand 3607 or 3707 with OD 0.38 mm. SPECIAL FEATURES — QUALITY ASSURANCE 100% Physical and Electrical testing (see below for test voltages ) A minimum of 3 layers of PTFE tape, wrapped and sintered, provides balanced bi-axially oriented, concentrically placed insulation (for more details about advantages of TWS method, click here) Minimum shrinkage/deformation and no `run-away’ problem at soldering-iron temperatures Surface as good as extruded wire without the disadvantages of extruded PTFE insulation in fine-gauge thin-wall types Certified minimum BREAK DOWN VOLTAGE (on samples) to ensure higher, uniform and predictable performance Controlled tigher tolerance on weight, PTFE density and conductor resistance Test voltages for the three common working voltages are: Type Working Voltage AC RMS Dielectric Test Voltage for 1 minute Spark Test Voltage for for 1 second ET 250 1500 2500 E 600 2000 3400 EE 1000 3000 5000 CAUTION Thin-wall insulation is not recommended for higher soldering iron temperatures and for gauges larger than AWG 20 Stripping of Tape-Wrapped-Sintered (TWS) PTFE insulation is generally difficult on automatic high-speed machines, more so, for thin-wall finer sizes ADVANTAGES OF PTFE INSULATION PHYSICAL/CHEMICAL Inert to practically all chemicals even at elevated temperatures Excellent Resistance to Ultra-Violet radiation and stress-cracking Non-contaminating, Non-toxic and bio-compatible Resistant to fungus and mould growth HIGH TEMPERATURE Excellent thermal stability — suitable for use from -200°C to 260°C Fire (flame) proof Soldering iron resistant and suitable for high density wiring ELECTRICAL Suitable for very wide frequency range (DC to above 10,000 MHz) over wide temperature range Lowest dielectric constant (2.1) Lowest dissipation factor (below 0.0003) Highest volume and surface resistivities (in Teraohms) Corona Resistance is fair (CR PTFE is available for severe corona conditions) MECHANICAL Smaller size, lighter weight and much higher reliability Cold-flow and cut-through resistance — fair (good mechanical strength) Excellent flex-life APPLICATIONS OF PTFE INSULATED WIRES & CABLES Electronic Test Equipment Communication Equipment (mobile and manpack wireless sets) Equipment for Aircraft, Radar, Navigation, Electro-mechanical applications, Satellites, Research Equipment for Aerospace, Navy & Meteorology Control Equipment for Atomic Energy, Satellite Launching, Ground Control, Reactors and Process Control, Telephone Exchange, Lifts Computers, Flight simulators High performance motors, transformers and rectifiers Infra-red sensing equipment Thermo-couple and compensating cables Air-field lighting equipment High temperature lighting fittings (sodium lamps etc.) Refrigeration equipment Load cells and pressure transducers Electro-medical/Neuro-surgical equipment High temperature control valves Furnace and oven wiring PTFE INSULATED SPECIAL EQUIPMENT WIRES Please refer to table for commonly available sizes. Within the normal range, larger number of strands are available to improve flexibility and flex-life; 19 strands up to AWG 30, 37 strands up to AWG 20 and 60 strands for AWG 9, 10, 11, 12 and 13. In the two larger sizes AWG 6 and 8, compact 61 strands true concentric constructions (compared to Rope lay 19 x 7) are about 15% lower in OD, weight and cost, although slightly stiffer. We offer finer sizes, having thin-wall PTFE insulation, highly flexible (with flex-life) constructions using Silver Plated High Strength Copper Alloy (SPHSCA). Sizes as small as AWG 37/7/45 (0.43 mm). Even such fine sizes are 100% tested. For Wire-Wrap wire, advantages of PTFE insulation are now available in single strand size up to AWG 36 (OD 0.43 mm), and multi-strand 3607 or 3707 with OD 0.38 mm. SPECIAL FEATURES — QUALITY ASSURANCE 100% Physical and Electrical testing (see below for test voltages ) A minimum of 3 layers of PTFE tape, wrapped and sintered, provides balanced bi-axially oriented, concentrically placed insulation (for more details about advantages of TWS method, click here) Minimum shrinkage/deformation and no `run-away’ problem at soldering-iron temperatures Surface as good as extruded wire without the disadvantages of extruded PTFE insulation in fine-gauge thin-wall types Certified minimum BREAK DOWN VOLTAGE (on samples) to ensure higher, uniform and predictable performance Controlled tigher tolerance on weight, PTFE density and conductor resistance Test voltages for the three common working voltages are: CAUTION Thin-wall insulation is not recommended for higher soldering iron temperatures and for gauges larger than AWG 20 Stripping of Tape-Wrapped-Sintered (TWS) PTFE insulation is generally difficult on automatic high-speed machines, more so, for thin-wall finer sizes

High Temperature Automotive Wires

Get Price Quote

HTAW™ automotive wires for continuous use at operating temperatures of up to -40ºC to +150°C (Class D), + 200ºC (Class F) and +250ºC (Class H), confirm first mover status in the development of forward-looking product technology. This new generation of automotive wires are suitable for vehicles with hybrid power trains and for fuel cell wiring applications. -40°C to +150°C (Class D) -40°C to +200°C (Class F) -40°C to +250°C (Class H) DESIGN CHARACTERISTICS : Conductor : Soft annealed electrolytic copper, Bare or Tinned or Silvered. Insulation : High Temperature Fluro Polymer, with properties similar to ISO6722.

High Temperature Wires

Get Price Quote

At MD Industries, we specialize in manufacturing insulated high temperature and high performance cable. For use where abrasion resistance is required. Recommended for mission critical applications such as: aviation, commercial, racing. D Industries is always been attentive in fulfilling the needs of its customer. As a result of this, MD Industries has recently started manufacturing High Voltage Power Cables up to 66KV.Reinforced with abrasion resistant mineral fillers. In view to meet rising demand of infrastructure needs MD Industries has been manufacturing 1.1KV aluminum Copper conductor with XLPE insulation more than a decade. This manufacturing plant is equipped with latest state of the art modern machinery to offer quality product at competitive prices.

high temperature wire

Get Price Quote

High Temperature Wire Suitable For 600°C / 600 Volts "High Temp." is designed for use in high temperature applications as a single conductor lead wire. It is recommended for use in areas that are exposed to high temperature with a minimum of flexing after installation. Features Superior mechanical performance. High temperature resistant to 600°C Short time 850°C Fire retardant. Resistant to radiation. Good performance at cryogenic temperatures. Maintains circuit integrity even when exposed to conditions of high ambient temperature and flame. Multiconductor constructions are available. Applications Motor lead wire. Wiring for ovens, kilns and industrial heating Products and leads for heating elements. Missile lead wire. Constructions Nickel coated copper, solid or stranded. Also available in "A" Nickel. High silica Fiberglass outer braid coated with a high temperature finish. Outer braid may be color coded, natural (tan) is standard.

PTFE High Temperature Stranded Wire

Get Price Quote

We are reckoned as a premium PTFE High Temperature Stranded Wire Manufacturer, Exporter & Supplier in India. The PTFE High Temperature Stranded Wire, offered by us, provides excellent resistance in heat, cold, chemical, solvent and abrasion. Our PTFE High Temperature Stranded Wire is widely used for internal wiring of appliances.

High Temperature Wires

Get Price Quote

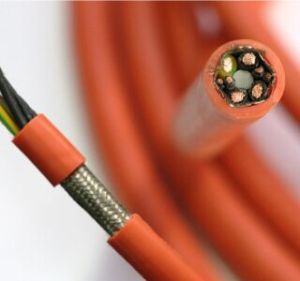

We can manufacture all types of shielded and braided control cables needed by various industries such as the drives & automation industry, elevator industry, motor industry and so forth.We produce cables used for applications as per the needs of the customer, which require most stringent tests including fatigue, dynamic load and fire retardance.

High Temperatures Equipment Wires

Get Price Quote

For any applications requiring resistance to high temperatures, Axon Cable offers a large range of equipment wires insulated with PTFE, ETFE, FEP or polyimide. Different versions of Mil-spec and commercial wires including single or multicore wires, extruded or taped, shielded and jacketed, extra flexible,wire-wrap wires and high flexible wires will meet your requirements. As a specialist in plastics technology, Axon’ Cable also offers a large range of radiation resistant wires and cables for nuclear and scientific applications, low smoke and zero halogen wires, cables which resist extreme temperatures.

High Temperature Alloy Wire

Get Price Quote

High Temperature Wires

Get Price Quote

We are reliable high temperature wires manufacturer, exporter and supplier. The high temperature wires, provided by us, have the ability to resist high temperatures. We manufacture the high temperature wires by using latest technology and premium raw materials. The high temperature wires are insulated with fiber glass, glass mica, asbestos insulated and stainless steel shielding, which enhances their capability and makes them durable. why our high temperature wires? best raw material useddurablelong lifediscounted rates availability : available up to 600 deg. Cent.

High Temperature Wires

Get Price Quote

GEEKORE is a leading company engaged in manufacturing high quality wires and cables. Incorporated in 1991, GEEKORE has passed its successful 19 years with enjoying its business with many of reputed OEMs and PSUs in the area of power transmission, electronics, military, defence and communication. We believe in technical competency and supplying consistent quality products to our end customers. We have two manufacturing units in Noida with plenty of space, efficient manufacturing and testing facilities.

High Temperature Wires And Cables

Get Price Quote

High Temperature Wires And Cables, Electric Cables, fep cable, pfa wire

High Temperature Wires

Get Price Quote

High Temperature Wires, Building Wires, cable assemblies, Cables

High Temperature Wires

Get Price Quote

High Temperature Wires, automotive wire, flexible straws

high temperature superconductor wire

Get Price Quote

high temperature superconductor wire, ferrous wire scrap

high temperature superconductor wire

Get Price Quote

high temperature superconductor wire, Railway Components, sleepers

high temperature wire

Get Price Quote

high temperature wire, high voltage cable, low voltage cable