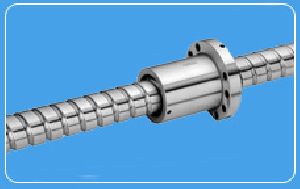

Hiwin Ground Ball Screws

Get Price Quote

1 Piece (MOQ)

Hiwin precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life. These highly efficient ballscrews are a perfect solution for a variety of applications.

hiwin ball screw

1,000 - 5,000 Per Piece

1 Piece (MOQ)

we are distributor of hiwin products

Best Deals from Hiwin Ball Screw

ground ball screw

Get Price Quote

Ballscrew Hiwin

Get Price Quote

HIWIN Rolled Ball Screw

2,850 Per Piece

1 Piece (MOQ)

Ball Screw

Get Price Quote

Ballscrew shafts HIWIN offers rolled, peeled and ground ballscrews - depending on the application requirements. For the selection of the appropriate shaft ...

Ball Screw

Get Price Quote

Ball screws are integral components in many modern mechanical systems, known for their ability to precisely convert rotational motion into linear motion with minimal friction. These high-efficiency mechanisms play a crucial role in various industrial applications such as CNC machines, automated manufacturing systems, medical devices, and robotics. When it comes to choosing the right ball screws, understanding the brands and quality options available is essential, particularly for businesses looking to optimize performance without compromising on cost. At New Jaydeep Bearing, we proudly offer a wide range of ball screws and linear guideways, from premium brands like Hiwin, PMI, THK, and NSK, to more affordable yet reliable alternatives. These products cater to industries that require precision, efficiency, and durability. --- The Role of Ball Screws in Modern Machinery Ball screws function by using ball bearings to roll between the screw shaft and the nut, converting rotational motion into linear movement. The ball bearings reduce friction, allowing for smoother, more precise movements. Due to their high accuracy and minimal wear over time, ball screws are ideal for applications that demand precise positioning, such as: - CNC Machines: Ensuring accuracy in cutting, milling, and drilling processes. - Robotics: Allowing for smooth and controlled movements in robotic arms and other automated systems. - Medical Devices: Facilitating accurate positioning in MRI machines and surgical tools. - Automated Systems: Enabling the precise movement of components in manufacturing lines. --- Hiwin Ball Screws: Precision and Performance Hiwin is a global leader in the production of ball screws and linear guideways. Known for their high precision, smooth operation, and long-lasting performance, Hiwin ball screws are perfect for applications that require tight tolerances and reliable performance over long operational lifetimes. - Durability: Hiwin ball screws are designed to

Ball Screw

2,000 - 10,000 Per Box

Ball Screw

Get Price Quote

Thomson company having manufacturing facility at sweden & usa develops linear actuators, linear guide units, lifting unit,ball screw & nut,bearing linear units with load range max. 40,000 n, speed up to 10 mtr/sec ; stroke length up to 12 mtr application scope : - replacement of hydraulic & pneumatic cylinder push, pull, lift, turn application with niche control requirement low weight unit for material handling machine building, axis motion special purpose machinery market served :- on –off highway vehicles robotics and industrial automation construction equipment machine building agriculture & forestry equipment handicap vehicles & medical equipment

HIWIN Ball Screws

1,500 Per Piece

1 Piece(s) (MOQ)

Hiwin Ballscrews consist of a screw spindle and a nut integrated with Hiwin rolling elements that cycle through a return mechanism. A ball screw is a mechanical linear actuator by Hiwin that translates rotational motion to linear motion with little friction. Hiwin is best suited for this job because of the quality we provide at an unbeatable price point.

Hiwin Axis Ball Screw

Get Price Quote

Ball Screw

111 Per Piece

Ball Screw

Get Price Quote

We are counted among the top Exporters and Suppliers of Ball Screw in the markets of Indian Subcontinent, Middle East, East Asia and South East Asia. A Ball Screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, Ball Screws can do so with minimum internal friction. Ball Screw is made to close tolerances and therefore suitable for use in situations in which high precision is necessary. The Ball Assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, Ball Screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. Description and Operation To maintain their inherent accuracy and ensure long life, great care is needed to avoid contamination with dirt and abrasive particles. This may be achieved by using rubber or leather bellows to completely or partially enclose the working surfaces. Another solution is to use a positive pressure of filtered air when they are used in a semi-sealed or open enclosure. While reducing friction, Ball Screws can operate with some preload, effectively eliminating backlash (slop) between input (rotation) and output (Linear motion). This feature is essential when they are used in computer-controlled motion-control systems, e.g., CNC machine tools and high precision motion applications (e.g., wire bonding). Advantages Low friction in Ball Screw yields high mechanical efficiency compared to alternatives. A typical Ball Screw may be 90 percent efficient, versus 50 percent efficiency of an Acme lead screw of equal size. Lack of sliding friction between nut and screw lends itself to extended lifespan of the screw assembly (especially in no-backlash systems), reducing downtime for maintenance, part replacement and decreasing demand for lubrication. This combined with overall performance benefit and reduced power requirements may offset the initial costs of using Ball Screws.

HIWIN Ball Screws

2,500 Per

1 Piece (MOQ)

ground ball screw

Get Price Quote

4.3 Accuracy Grade of HIWIN Ballscrews Precision ground ballscrews are used in applications requiring high positioning accuracy and repeatability, smooth movement and long service life. Ordinary rolled ballscrews are used for application grade less accurate but still requiring high efficiency and long service life. Precision grade rolled ballscrews have an accuracy between that of the ordinary grade rolled ballscrews and the higher grade precision ground ballscrews. They can be used to replace certain precision ground ballscrews with the same grade in many applications Accuracy grade There are numerous applications for ballscrews from high precision grade ballscrews, used in precision measurement and aerospace equipment, to transport grade ballscrews used in packaging equipment. The quality and accuracy classifications are described as follows: lead deviation, surface roughness, geometrical tolerance, backlash,drag torque variation, heat generation and noise level. HIWIN precision ground ballscrews are classified to 7 classes. In general, HIWIN precision grade ballscrews are defined by the so called “V300p” value see Fig 4.12 and rolled grade ballscrews are defined differently as shown in Chapter 7. Fig. 4.12 is the lead measuring chart according to the accuracy grade of the ballscrews. The same chart by the DIN system is illustrated in Fig. 4.13. From this diagram, the accuracy grade can be determined by selecting the suitable tolerance in Table 4.2. Fig. 4.14 shows HIWIN’s measurement result according to the DIN standard. Table 4.2 shows the accuracy grade of precision grade ballscrews in HIWIN’s specification.The relative international standard is shown in Table 4.3.The positioning accuracy of machine tools is selected by ep value with the V300p variation. The recommended accuracy grade for machine applications is shown in Table 4.5. This is the reference chart for selecting the suitable ballscrews in different application fields. Axial play (Backlash) If zero axial play ballscrews (no backlash) are needed, preload should be added and the preload drag torque is specified for testing purpose. The standard axial play of HIWIN ballscrews is shown in Table 4.4.For CNC machine tools, lost motion can occur in zero-backlash ballscrews through incorrect stiffness. Please consult our engineers when determining stiffness and backlash requirements. Geometrical tolerance It is crucial to select the ballscrew of the correct grade to meet machinery requirements. Table 4.6 and Fig 4.15 are helpful for you to determine the tolerance factors, which are based on certain required accuracy grades.

Ball Screw

Get Price Quote

We are the distributor and wholesale suppliers of ball screw product in all types and we supply this qualitative product in all over domestic market at competative price.

hiwin ball screw

2,500 - 100,000 Per Piece

1 Piece(s) (MOQ)

Ball Screw

500 Per unit

Ball Screw

Get Price Quote

We make and supply of Ball Screws in Chakan, Maharashtra, India. Durable in nature, offered Ball Screw is damage resistant and available for buyers in different diameters. This screw is small in size and easy to install. Safe from damage by high pressure, offered screw is superior in quality and accurate in dimension. Moreover to this, screw has longer life.

precision ball screw

1,000 - 100,000 Per Kilogram