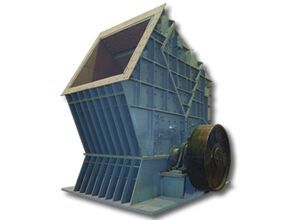

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)

Best Deals from Horizontal Shaft Impact Crusher

Horizontal Shaft Impact Crusher (HSI)

1,500,000 - 3,500,000 Per Piece

1 Piece (MOQ)

Crushing by impact, as distinguished from crushing by pressure, has its own advantages. Pressure is applied instantaneously during crushing and therefore, breaking by impact almost eliminates the possibility of the development of hidden cracks in the products. This aspect is to noted particularly for road metal.

Horizontal Shaft Impactor

100,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Horizontal Shaft Impactor

Get Price Quote

The Horizontal Shaft Impactor, which we supply, is known for its make and long service life. We stringently make complete arrangements for the vigil examination of the inputs used for the products. By this, we are capable of bringing forth reliable products that are presented after complete inspection and examination by the experts. Our warehouse is well constructed and equipped with all required amenities essential for a safe storage of the products. We also make sure that proper hygienic conditions should be maintained inside the unit.

Horizontal Shaft Impact Crusher

2,000,000 Per Piece

Horizontal Shaft Impactor

500,000 - 3,000,000 Per Nos

HSI Impactor

Get Price Quote

1 Piece (MOQ)

Horizontal Shaft Impact Crusher

Get Price Quote

Rugged Construction suitable for Primary and Secondary application Best suited for hard materials like basalt and granite Extremely sturdy and all the parts are easily accessible for quick maintenance. High utilization of breaker bars and can be quickly reversed or replaced Rotor fabrication is well balanced to minimize vibration.

Horizontal Shaft Impactor

Get Price Quote

Rullitech Impactors are used as primary and secondary crushers for size reduction of various materials like limestones, Basalt, Blast furnace slag, coal, dolomite, gravel, concrete, asphalt etc., in wet and dry applications. These Crushers offer operators a very high ratio of reduction and can accept larger feed sizes. There are no screens at the discharge opening, thus avoiding plugging. Rullitech Impactors are specially designed to ensure reliability along with easy maintanance, interchangeable wear parts and fast replacement. These crushers require less capital outlay and produce higher percentage of cubical shaped products than competitive type crushers. Operation : Feed enters the primary crushing chamber and meets the blow bars, which impel the feed against the front breaker plate assembly. This action and the collision of material sufficiently reduced in the primary chamber passes by the front breaker plate assembly and enters the secondary chamber for final reduction. Feed Opening : Rullitech Impactors features a very large feed opening. Which enables optimum utilization of the impact chamber, with high capacity rates and excellent size reduction ratios. In, addition, plugging of the material is avoided. Blow Bars : The blow bars are reversible, enabling logner life and less stock keeping. Breaker Plate Assembly: The Breaker plate assembly can be optimally adjusted for particular applications. The breaker plate reaches till below the last crushing element of blow bar. The breaker plates are made of welded steel and are mounted with replaceable blow bars. Rotor : The rotor is mounted on a large diameter forged shaft, which is supported by over-sized, self-aligning, roller bearings located in heavy-duty split bearing housings. The blow bars of the rotor are held in the rotor by a simple locking device. The complete rotor assebly is hard-surfaced in critical areas and thermal stress relieved. Housing : The housing is fabricated with heavy ribs. It is also hinged and has big inspection doors for ease in maintanance. Drive : The Impactor is driven by V-Belts and Electric Motor. Key Features of Horizontal Shaft Impactor: Heavy Duty solid rotor construction. Two, three and four row configurations. Greased oversized bearings. Blow bars available in manganese and various compositions of chrome steels. High Reduction ratios to 30:1. High throughput capacity. Cubical product with high crush count. Selective crushing by speed and breaker plates adjustment. Interchangeable wear parts. Maximum operating reliability. Ease of Maintanance and service.

Horizontal Shaft Impactors

Get Price Quote

"kingson" series of horizontal shaft impacter is widely applied in mining,, energy and chemical industry. Horizontal shaft impactor has reasonable structure, high productivity, easy maintenance and safe performance. The most outstanding benefit of this machine is that its finished product is in good cubic shape, non-tensile and cranny.

Horizontal Shaft Impactors

Get Price Quote

1 Piece (MOQ)

We are offering Horizontal Shaft Impactors. These are built with an exclusive combination of standard features that provide value , performance and durability. These crushers with integrated hydraulics are ideally suited to crush hard , abrasive materials down to cubical having a high reduction ratio. capcity range: 50 - 300 tph. models: hs1000 (1000 mm rotor diameter), hs1300 (1300 mm rotor diameter)

Horizontal Shaft Impactors machine

Get Price Quote

This is a Heavy Duty Machine. The Material is crushed by impact of Hammers fixed on the outer edge of a spinning rotor. These are used as Secondary Crushers and are designed to crush tougher materials like Basalt, Granite, Quartzite, River Gravel etc.

Horizontal Shaft Impactor

Get Price Quote

Horizontal Shaft Impact crushers deliver unbeatable performances in primary, secondary, tertiary and recycling applications. It can crush material like Black basalt, limestone, dolomite, Iron ore, Coal.etc. The maximum feed size side of which is between 150-200mm, and the final product is ideal device for aggregation use.Horizontal Shaft Impactor has been designed to minimize maintenance and improve all adjustment operations. This impact crusher features reasonable structure, high productivity, easy operation and maintenance and safe performance. The most outstanding advantage of this machine is that its finished material is in cubical shape.

Horizontal Shaft Impector

Get Price Quote

Impact crusher HSI : HIC impact crusher can be used for variety of jobs, including crushing of rock in quarries (limestone, dolomite, sandstone, gravel, etc,) and processing of building waste for recycling (concrete, brickwork, debris, bituminous materials at road reconstruction) HSI crushers many advantages: ► Advanced technical level which increases the affectivity of the operation ► High degree of comminuting, can be enhanced by incorporation an extra crushing route ► Variable construction of the box to incorporate the HIC crusher into stationary lines or mobile equipment ► Enclosed rotor body, fixed attachment of crushing bars in rotor Compact solution of flexible units, impact plates and crushing plate slot adjustment An easy access of operator during maintenance due to hydraulic opening of the crusher body ► High quality= highly range of HIC crusher application Variable design wide range of HSI crusher application : There is a wide range of application of HIC crushers due to variability of their design. The equipment can be adjusted to either stationary or mobile application by changing the location of the feeding hopper. The mobile adjustment complies with the requirements for the minimum height of the feeder and protection against shooting of the aggregate out off the internal space of crusher. The extra accessories, the crushing route, of the HIC crusher increase the crushing effect and the combination of the crusher material. The name of the crusher with the crushing plate includes mark The HIC crusher can be adjusted to crush materials with higher abrasion. The HIC crusher, which crushers abrasive material, includes A in its name.

HORIZONTAL-SHAFT IMPACT CRUSHER

Get Price Quote

South is celebrated for its high-quality crushers in the industry. South Cedarapids 1313 series horizontal-shaft impact crushers keep South continue to maintain a leading position. These crushers require a large amount of material filling during impact crushing and have heavy impact plates and robust rotors. As a result, they can process materials in large sizes and have a high crushing capability. In addition, their unique wedge fixing system improves the reliability and simplifies maintenance, while their wear-resisting hard surfaces can ensure a long-time operation in harsh environments. These and other characteristics show that the 1313 series horizontal-shaft impact crushers feature a high output, a low maintenance rate and a long service life, which can bring you a high return on investment.

Horizontal Shaft Impact Crusher

Get Price Quote

SINGH range of Horizontal shaft Impactors are state of the art equipment manufactured as per International Standards using high quality raw material. The crusher is designed to crush in two or three stages for minimum wear and tear of parts; the incoming feed first strikes the blow bars on the rotor and is then impacted on the primary curtain. When the material is reduced to a stage where it can pass the primary curtain, it is then impacted on the secondary curtains where the final sizing of the finish product is acquired by the setting of gap. Grinding stage can also be fitted so that maximum fines can be achieved in just a single pass. The scientifically designed SINGH horizontal Impactors reduce your crushing stages due to their high performance, which not only saves your capital cost but has a lowering effect on energy charges. The current and future operating conditions are getting increasingly stringent, and the answer is SINGH Horizontal shaft Impactor. The best performance from a Horizontal shaft can be achieved only with the right and optimized machine layout, a perfectly designed crushing chamber, specific rotors and liners. The proper combination of SINGH’s large feed opening, high reduction ratio, high capacity, low investment and operating costs can multiply your profitability many fold.

Horizontal Shaft Impactor

Get Price Quote

We are a prominent Supplier of Horizontal Shaft Impactor across India. We supply Horizontal Shaft Impactor up to 300 TPH. The Horizontal Shaft Impactor or Coal Impactor that we offer is strong, reliable and easy to operate. Our corrosion resistant Horizontal Shaft Impactor is available at very competitive price.

Horizontal Shaft Impactor

Get Price Quote

FEATURES OF MAXWELL HORIZONTAL SHAFT IMPACTOR Higher Capacity with simple structure. Easy handling of rotar blade replacement High Effciency and energy conservation. Easy adjustment of breakers blades. Full body protection through efficient and cost effective liners.

Horizontal Shaft Impactor

Get Price Quote

1 Piece (MOQ)