Hot Dip Galvanizing Plant

Get Price Quote

Corrotech executes all of its projects professionally managed by a dedicated project team with a director taking personal responsibility for the smooth running of each project. Our core market sectors include power transmission, electrical substations, telecommunication, solar energy, roads & bridges and many more. We have the experience of getting involved in many successful & prestigious galvanizing plants worldwide, and have designed, fabricated, installed complete engineering solutions within the hot dip galvanizing industry. we execute projects that involve all elements of the project life cycle from project start, right through the detailed design and installation. As part of our turnkey project execution of the galvanizing plant we offer the full range of functions: • project management & engineering • feasibility study • capital expenditure & justification • process design & engineering • plant layout & design • finalize technical specifications • design and supply of various equipment • construction supervision & management • health safety & training • commissioning & start-up we always follow a flexible approach when tackling the varying client’s demands of turnkey projects. As a strategy we cultivate value added partners to supplement and enhance our skills, as well as to cover specialist design or services. This allows us to offer our clients the full process and financial benefits of the ‘best in class’ technology available. our extensive experience across galvanizing industry encourages the generation of ideas and the adoption of best practice techniques. It is our motto to continue to develop and expand the scope and depth of our project capabilities, and to realize our full potential as a company.

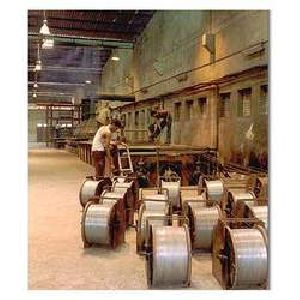

Hot Dip Wire Galvanizing Plant

Get Price Quote

We are engaged in manufacturing and supplying wide range of Hot Dip Galvanizing Plant to our clients. These products are manufactured using high quality basic material, procured from the trusted vendors of the market. Professionals of our team have manufactured these products in complete compliance with international standards of quality. These are widely demanded by our clients for their sturdy construction, excellent durability and reliable performance. Clients can avail these at affordable prices.

Best Deals from Hot Dip Galvanising Plant

MINI HOT DIP GALVANIZING PLANT

3 - 50 Per Nos

We are the manufacturer of hot dip galvanizing plant with the plant length ranges from 0.5 m to 13 m long and also as per customers requirements.

hot dip galvanising plant

Get Price Quote

Hot dip galvanising plant is require for the pipes. So that acid is to be circulated in all direction of pipe inside & outside surface of the pipe. The arrangement is made to rotate the pipe in high direction & cleaning is made for the effective galvanising.

Hot Dip Galvanizing Plant

Get Price Quote

Hot dip galvanizing on the surface of Steel, aluminium and iron metal with zinc coating for long lasting and quality finishing by professionals as per the client's need and demand. Hot dip galvanizers used in the processing of galvanizing by our organization as Precimax online to deliver the best solutions that's why we are appreciated by our clients and clients positive feedback is our main assets. Galvanization is the process of coating defensive zinc coating on steels and irons into classify to find rusting, we take all cautions and supply and offer best to hot-dip galvanising plants since 1962 over more than 400 clients. Galvanizing equipments is the total option of products which is included as hot dip galvanising crash guard and guard rail, Galvanizing Plant, General Galvanizing Plant, Galvanizing Plant for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanising is design and developing for the utilizing high grade of raw materials and heavy hot dip Galvanizers machine in harsh conjunction with the industry set the norms and levels. Hot dip Galvanizing is usually very well tested in unique details in order that defect free products usually are sent from consumers' place. Hot dip Galvanizers give some advantaged like limited pickling time period, short manufacturing charge, reduced creation price tag, improved productivity etc.

hot dip galvanising plant

Get Price Quote

Hot Dip Galvanizing is the process of applying a zinc coating to fabricated iron or steel material by immersing the material in a bath consisting primarily of molten zinc. The galvanizing process has a distinct Advantage providing corrosion protection.

hot dip galvanizing plants

Get Price Quote

We are offering hot dip galvanizing plants. Plast world introduce ourselves as a leading manufacturer, supplier and exporter of a comprehensive range pickling tanks such as pickling plants for galvanizing tower , pickling plants for transmission tower, pickling plants for s.s. M.s. Pipes ,tubes , wire coils, stripe etc. We design pickling tanks that are used by galvanizing plants manufacturers for usage in high tension transmission tower , poles, pipe cable trays ,grating , guard, tails, railing and other steel items.

Hot Dip Galvanizing Plant

Get Price Quote

Our Hot Dip Galvanizing Plant has long service with least maintenance. We have developed state-of-the-art storage facility wherein we keep a large stock. It also prevents our offerings from air, duct, sunlight and other damaging factors. We are supported by a reliable team of packaging experts who have immense experience in this domain and capable of catering to the standards and customized packaging requirements.

Hot Dip Galvanizing Plant

Get Price Quote

Planning & construction of tank system with fume exhaust system. Robust design of tank made out of Industrial Thermoplastic. Environment friendly Fume Extraction System, avoiding corrosion of surrounding steel construction, cranes and roof structure. Plastic Tanks available in flat pack modules (reduced volume) Heating and circulation system available. (optional) Tank made from Industrial Thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relieved. Modules assembled and welded at site for easy transportation.

hot dip galvanising plant

12,000,000 - 20,000,000 Per Piece

1 Piece (MOQ)

Hot Dip Galvanizing Plant

Get Price Quote

Arvind Corrotech is a leading supplier of turnkey hot dip galvanizing plants that guarantee great performance, productivity and efficiency. Starting from scratch by providing a customized design to commissioning, we get along with you in the process to set a high-performance galvanizing plant.

hot dip galvanising plant

Get Price Quote

In House Fully Equipped Ultra Modern Hot Dip Galvanizing Plant Hot Dip Galvanizing With Eot Cranes, Zigging & Trolleys, Hoist, Testing Labs, Etp Plant And Fume Extraction System

hot dip galvanising plant

Get Price Quote

Surface preparation is the most important step in the application of any coating. In most instances, where a coating fails before the end of its expected service life it is due to incorrect or inadequate surface preparation. With galvanizing, the surface preparation process contains its own built-in means of quality assurance and quality control in that zinc will simply not react with a steel surface that is not perfectly clean.

hot dip galvanising plant

Get Price Quote

Valmont Structures offers hot-dip galvanizing services which prolong the lifetime service of steel poles, monopoles and related steel structures. The lead-free bath size at our facility in India is 16.3 M long x 2.5 M wide x 3.3 M deep.

Hot Dip Galvanizing Plant

3,200,000 Per Units

1 Units (MOQ)

Hot Dip Galvanizing Plant

Get Price Quote

As a dependable Supplier from Nashik(India), we ensure that our customers obtain only quality assured products. We efficiently carry out systematic process at every stage, to make certain that the product basket is developed as per the specified requirements.

hot dip galvanising plant

Get Price Quote

Our firm is renowned as a leading manufacturer and supplier of a world class range of Galvanizing Tanks which are developed in adherence set industry norms. These tanks are precisely engineered using finest quality material which is been sourced from certified vendors of the market. We offer our range as per the information laid down by our esteemed customers.

Hot Dip Galvanized Wire Plant

Get Price Quote

Assomac group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. Assomac has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead coil opener type Pay Off, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuperator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintenance required. Stainless Steel SS-316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criteria in today's plants. Zinc Bath furnace consisting of Structural Steel Frame which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for light / medium and heavy coating available. Zinc coated control through pad wiping, spring wiping for low & medium coating & vertical charcoal or nitrogen wiping for heavy coating can be provided. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical drop coiler with or without pattern lay and strip take ups in our manufacturing programe.

Hot Dip Galvanizing Plant

Get Price Quote

hot dip galvanizing plant oil removal from the surface of steel, It is immersed in acid base degreaser.To clean the surface of carry over salts for effective acid cleaning.The rust scale & mill scale are removed from the surface of the steel by passing it through 15 to 20% conc. HCL.

Hot Dip Galvanizing Plant

Get Price Quote

Since our inception, we are instrumental in offering premium quality Hot Dip Galvanizing Plant. The offered galvanizing plant is meticulously tested on various quality parameters and is widely demanded in various industries. Provided galvanizing plant is manufactured by utilizing optimum quality raw material and the latest technology at our manufacturing unit. In line with the international standard, we provide the entire range in various customized options and at affordable prices.