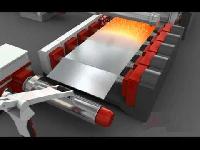

hot plate mill

Get Price Quote

3,00,000 MT per year HR Plates of max. 2100mm width and thickness from 6-60 mm; 5,00,000 MT per year HR Coils of max. 1550mm width and thickness from 1.2-10 mm The forming stage in the production is initiated by the Hot-Rolling process. The Stainless Steel slabs are heated and passed through huge rolls. The slabs are rolled into thinner plates, strips and sheets. A heat treatment follows, involving the processes of annealing and quenching. This relieves internal stresses and softens the metal. The plates and coils are then subjected to shot blasting that clears the slab surface of scales.

hot plate mill

Get Price Quote

The mill is equipped with walking beam type of reheating furnace where slabs are re-heated at a temperature of 1250 degree celsius and rolled in a mill with a 2 hi-reversing type roughing stand and a 4 hi-reversing type finishing stand. To ensure excellent surface quality, high pressure de-scalers are provided at the entry and exit points.

Best Deals from Hot Plate Mill

hot plate mill

Get Price Quote

Modern Engineering Works with its experience and expertise spanning over two decades has been involved in manufacturing of quality Mechanical Equipments, Fabrications & Spares for Slab charging & discharging assembly.

hot plate mill

Get Price Quote

We provide a wide range of hot plate mill

hot plate mill

Get Price Quote

hot plate mill, Cold Rolling Mill, hot rolling mill

Plates from Hot Strip Mill

Get Price Quote

Plates from Hot Strip Mill, Galvanized Roofing Sheets, blooms, Billets