hot air humidification system

Get Price Quote

1 Piece (MOQ)

Feature Instant / Online humidification Increases bale weight Reduces pressing force Reduces power per bale Improves lint grade & appearance High quality construction for longer life Improves fibre parameters Humidifiers with disel / gas / kerosene burner suitable for 1700 1700 CMH of hot humid air & 204 litres of peak evaporation capacity Hot Air Humidification or Hot Air Moisture restoration in a cotton gin can have a huge impact on profitability. Some of the salient features are given below: nstant humidification by easing out wax surface of the fibre and recuperation after humidification by cooling effect for retained moisture. Preserves fiber length, improves strength and uniformity and reduces short fiber content. Eliminates moisture condensation which is a general problem with all other moisturisation techniques. Increases the lint slide capacity and allows more cotton to enter the press box at each stroke of the tramper and hence higher density bale is obtained. Improves the capacity of the bale press whereas dry cotton requires higher compression forces and more time to charge and compact it into the press box. Achives better sliding of lint in the lint slide. Hot Air Humidification applications: Hot humid air is inducted in the lint on a lint slide with a set of louvers at temperature around 45 to 50 Degree celcius. The hot air eases out the surface tension of the fibre and humidity is transfered to inner stem while air passes out. The cooling down recuperates the fibre surface and maximum moisture contents are retained by fibre for a longer period. Our systems consists of : Moist Air Generator: Humidifiers with disel / gas / kerosene burner Moist Air Applicators: Lint Slide or Humidification Belt Conveyor This is a unique device manufactured by Bajaj Steel Industries Limited in technical collaboration with M/s. Inc. USA. for moisture restoration in cotton lint applying psychrometric principles. It is a high temperature Humidifier for generation of Humid hot air free from water droplets. The vapour phase transfer of moisture at the diffuser assures controlled and positive enhancement of moisture content in lint to highest acceptable level, as per international standard. This reduces pressing force of bale press resulting in lower power consumption per bale and increases bale weight.

Cotton Lint Humidification System

Get Price Quote

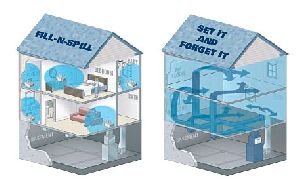

Cotton lint humidification and moisture restoration system is a patented product of steamtech engineers and it restores cotton moisture automatically which is reduced during the ginning process. After formation of cotton lint bales, moisture retention system retains moisture content in bales which are stored in godowns. Operating Principle The operating principle of Cotton lint humidification system is, Vapor is generated and cotton is humidified up to desired extent automatically in controlled environment irrespective of external weather. Benefits Strength of cotton fiber is improved. Even humidification can be achieved in whole cotton bale. Colour of cotton fiber is improved. Humidification can be done in accordance to international standards. It prevents formation of fungus in the cotton bales when stored for longer duration. Special Features PLC provides controlled humidification of specified percentage round the clock unless changed. It has sturdy and robust body Another Benefits Modular Construction : The sectional construction reduces the time in project planning, manufacturing, transportation, and finally installation. Energy efficiency: Vapour flow can be managed individually as per the requirement to make sure optimum humidification. Process adaptation: Each parameter such as Vapour flow, Temperature, Retention time of product can be individually managed exactly to suit your humidification requirement. Make in India: The machine is 100% indigenous and patented. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

Best Deals from Humidification Systems

Humidification System

Get Price Quote

One of the most sought after Manufacturers and Suppliers of Humidification System, we are a renowned name in this domain. To meet industry specific and application specific requirements, we offer Evaporative Humidification and Steam Humidification. With the team of professionals, complete automated system is designed, supplied and installed. We have state of the art manufacturing unit that is equipped with latest machines and technology.

textile humidification systems

35,800 Per Units

1 Units (MOQ)

textile humidification system

Get Price Quote

We are the most promising name, involved in supplying textile humidification system. Ours is a well-established firm located in Coimbatore(India) and engaged in the business of providing a wide assortment of quality products.

humidification plants

Get Price Quote

Humidification plants, DE-HUMIDIFIER EQUIPEED WITH HERMETICALLY SEALED RECIPROCATING OR SCROLL COMPRESSOR.DE-HUMIDIFIER AVAILABLE WITH REFRIGERANTS R22, R134 A, R407C, R404A OR R410A. CONSTRUCTION BODY: M S. POWDER COATED OR FULYY STAINLESS STEEL 304 SHEET & ANGLE. HIGH QUALITY FAN MOTOR WITH LOW NOISE. EQUIPEED WITH ALL ELECTRICAL SAFETY DEVICES LIKE COMPRESSOR OVER HEAT PROTECTION, OVER CURRENT PROTECTION, OVER TEMP PROTECTION , ANTIFREEZE PROTECTION.

Humidification System

Get Price Quote

We state our payment terms on the invoice we sent to our clients. Moreover, our payment procedures remain simple and free from any sort of hassles. We offer both online and offline payment processing. Located in New Delhi(India), our company is involved in making available wide array of products that are in conformance with the industry standards.

Humidification Plant

Get Price Quote

1 Piece (MOQ)

We have established ourselves as coveted organization, involved in manufacturing, supplying and exporting a wide gamut of Cooling Tower Spare Parts. These parts are developed and designed using high grade raw material mainly stainless steel in compliance with industry laid norms and guidelines. Owing to excellent features such as high tensile strength, high durability and low maintenance, our entire range is widely demanded by our valuable clients. Further, clients can avail these parts from us in a wide range such as Drift Eliminator, Drive Shaft, FRP Fan, Cooling Tower Gear Box, Aluminum Alloy Rotating Sprinkler, FRP Casing Panels, PVC Fills and Stainless Steel Wire Mesh.

industrial humidification system

7,500 Per Piece

Humidification System

Get Price Quote

textile humidification system

100,000 - 300,000 Per piece

3 Units (MOQ)

Textile Humidification Plant

Get Price Quote

Both of our online and offline payment processing methods are secure for transaction offering you a reliable assistance. We thus accept all kinds of cash payments as well as bank transfers. If you are interested in obtaining Humidification Plant at market leading prices, we are its responsible and responsive suppliers.

Humidification System

Get Price Quote

Textile Humidification Plant

Get Price Quote

The company is known as the major manufacturer, exporter, and supplier of the advanced textile humidification plant in india. Manufactured as per the industrial standards, our textile humidification plant is known for its excellent performance. The textile humidification plant can be availed at competitive prices from us. used for production of textile yarns known for efficient performancelong working lifesturdyadvanced technology

Humidification System

Get Price Quote

We are offering humidification system. The eshan make humidification systems are designed to clean the air and reduce the temperature of the air and leaving out as cooled air by evaporating method. These humidification systems are widely used in the pharmaceutical,auditorium,textile and food industries. The humidification efficeicy will be more than 95%. Our humidification are backed by good service.

Box Type Eliminator Frame

Get Price Quote

All our payment terms and conditions are as per the requisites of law. A payment agreement signed with the patrons is fulfilled by us ethically and with a high level of transparency. We keep the finished assortment of products in highly developed and spacious space. This helps us in keeping products secure and sorted.

Humidification System

Get Price Quote

Humidification Plant

Get Price Quote

NJTT LEGION introducing a fermenting Drums climate controlling system, which can support six drums erected in row. VHDP6 FERmATA will be connected to fermenting drums through six individual ducts for inlet and six ducts for outlet. This system operates to maintain 28oC +- 2oC and RH @ 75% to 85% at any at any atmospheric temperature. This system specifically designed for CTC Drum ferm

humidification plants

Get Price Quote

The fan impellers are specially designed for high static pressure and better efficiency, cost out of aluminium alloy. The blades are dynamically balanced. The blades are site adjustable from 12.5˚ to 30˚

Humidification System

Get Price Quote