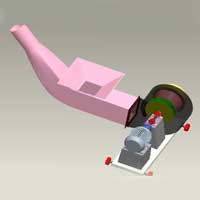

sunflower seed de-husker

55,000 - 56,000 Per piece

Sunflower seed Dehusker / sheller (Rubber Disc Sheller) Available Capacity:200-1000 kgs/ hr Power Required: 2-5 HP Diesel Engine/Electric Motor (Also Suitable for Sunflower Seed, safflower seeds, chironji, Buckwheat, Oats, Millet etc.,)

Automatic Coconut Dehusking Machine

125,000 - 250,000 Per piece

1 piece (MOQ)

Coconut dehusking is the process of removing the husk or outer covering of a coconut fruit. Traditionally, this process has been done manually using tools like machetes or spikes, which requires skill and training. However, there is a shortage of skilled workers, leading to lower production rates and safety hazards.

Best Deals from Husking Machine

Groundnut Decorticator with 4 HP Motor

74,000 - 90,000 Per Machine

1 Piece (MOQ)

Groundnut Decorticator

Get Price Quote

1 Pieces (MOQ)

This is a simple machine and its working is easy and trouble free. This is suitable for small units and has the capacity of 800 lbs of decorticating seed in an hour This unit employs friction rolling method to break open the shell with minimum break-age of seeds. The construction is simple, it has a steel frame, adjustable hopper and sieve is of strong section bars to allow adjustments for different size of seeds to fall through. The main shaft has moving wheel on side and fly wheel on the other side. The shaft is supported on ball bearings and heavy fly Wheel ensures the smooth and free movements. The fan bearings are ordinary or self oiling . All the parts are made out of selected materials and are properly machined to give smooth service. This machine can also run on power of 11/2 to 2 H. P. POWER DECORTICATOR These are available in two sizes, each unit has strong Steel Body and is of simple constructions. It is easy to handle and has low maintenance cost. The hoppers fitted to the upper part of the frame and seed passes through the opening chamber, where the shell is broken and separated from the kernel. The kernel and the shells fall through the sieve to the slide board, where the fan blower further clean the kernel before they fall out of machine. THE STONE SEPARATOR is provided with power decorticators only.Two pullies are provided one of beater size Note: We reserve the right to make alteration in the machine from time to time as required.

Groundnut Decorticator 500KG

100,000 - 130,000 Per piece

1 piece (MOQ)

Paddy Husker

Get Price Quote

We present Paddy Husker, which is widely appreciated by the clients due to its high quality and long operational life. We are one of most trustworthy Paddy Husker Manufacturers, Exporters, and Suppliers located in India. Our Paddy Husker comes with rubber roll Sheller and aspirator for separating the husk. Our Paddy Husker is ideal for both dry & wet samples of various kinds.

Almond Decorticator

Get Price Quote

We are prominent Manufacturer, Exporter and Supplier of Almond Decorticator from Rajkot, Gujarat. Top-notch quality material is used for manufacturing Almond Decorticator in accordance with the set quality standards. Our Almond Decorticator id appreciated due to its robust construction and fine quality. Customers can approach us for acquiring Almond Decorticator at market leading rates.

Groundnut Decorticator Plant

750,000 - 950,000 Per One Unit

Butterfly Paddy Rice Separator

500,000 Per Piece(s)

1 Piece(s) (MOQ)

We source the raw material from the leading vendors and manufacturers in the market; thus, we are capable of fulfilling the exact requirements of the clients with our offered products. We have a capacious warehouse facility that assists us completely in making stock and furnishing varied requirements of the clients. Also, our facility is equipped with modern storage amenities. Other Details : Butterfly Paddy Separator is used for any kind of Rice varieties This machine is known for its compact size, high production, easy operation, low maintenance cost, low driving power and highly performance Additional Information : Item Code - PPS

PNEUMATIC DEHUSKER

300,000 Per Piece

Rice Palm Husker

Get Price Quote

10 Piece (MOQ)

Broken Separator Tray

300 Per Piece

20 piece (MOQ)

Rice Husk Blower

Get Price Quote

Our range of portable Rice Husk Blower is used for stacking husk. The Rice Husk Blower that we offer is fabricated by using advanced technologies and modern equipment. These blowers are highly efficient and they assure error-free operation. Apart from this, these blowers are high on demand in the sugar mills and are even priced cost-effectively. Renowned For : Fast stacking of husk Non-contact blades Longer life Very fast operation Suitable For Drying : Sawdust Rice hull Milling wheat straw Corn stalks

Broken Rice Separator

Get Price Quote

(Having 4 indented plates and 1 flat plate with A nice pouch) Indent Size : 3.5mm, 4.2mm, 4.6mm, 4.8mm

Paddy Separator

Get Price Quote

We hold expertise in manufacturing and supplying high performance Paddy Separator. Paddy Separator, which we offer, is precision engineered using top grade raw materials. The offered Paddy Separator is appreciated for its long service life and requirement of less maintenance. Avail Paddy Separator from us at the most competitive prices.

Paddy Dehusker

Get Price Quote

1 Piece (MOQ)

Backed by rich industry experience and market understanding, we are involved in offering a wide array of Mini Paddy Dehusker to our valued patrons.

Groundnut Decorticator Machine

Get Price Quote

1 Piece (MOQ)

Double Shaft Coconut Husk Shredder Machine

300,000 - 500,000 Per piece

1 piece (MOQ)

A green as well as brown coconut shells can be shredded in our double shaft shredder which is used to shred large quantities of coconuts fast on a daily basis, for SHREDALL quality and reliability are paramount. We take pride in offering top-of-the-line double shaft coconut shredders that are built to last even in outdoor conditions. Our products are not only high-quality but also come with unbeatable prices and warranties, making them a smart investment for businesses worldwide. With our commitment to excellence, we ensure that all our small, medium as well as large coconut shredders are manufactured to the highest standards, delivering efficient and reliable performance with every use. Whether you need in the farm or are in the food industry or agricultural sector, our agri shredders are designed to meet your specific needs and exceed your expectations. When you choose SHREDALL for your coconut shredding needs, you can trust that you're getting a superior product that is built to last. Experience the difference with our world-class coconut shredders – shipped worldwide for your convenience. The Basics of Double Shaft Coconut Shredder The double shaft coconut shredder represents a significant advancement in shredding technology, specifically designed to address the unique characteristics of coconut husks. Unlike conventional shredders, which may struggle with the tough and fibrous nature of coconut husks, the double shaft design ensures thorough and efficient shredding. Key Features Dual Shaft Configuration Robust Construction Versatility Efficient Drive System Safety Features Easy Maintenance Shredding Material The machine is designed to handle Coconut Usage/Application The double shaft coconut shredder finds applications across various industries and sectors, including: Coconut processing plants: Efficiently processes coconut husks and other waste materials generated during coconut processing. Agricultural industries: Facilitates the conversion of coconut waste into valuable resources such as mulch, compost, or biofuel. Waste management facilities: Contributes to sustainable waste management practices by shredding coconut waste for recycling or disposal. Capacity With a shredder from 100 kgs/hr to 5000 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is Automatic, which makes it easy to operate. Motor Power The machine runs on a 3-phase power supply, ensuring efficient and reliable performance. Country of Origin Made in India, the SHREDALL industrial Shredder Machine are designed and manufactured entirely in INDIA. Product Description Coconuts are not only a popular tropical fruit but also a source of various byproducts, including coconut husks. However, managing coconut husk waste efficiently has long been a challenge due to its tough and fibrous nature. Traditional methods of disposal often lead to environmental pollution and resource wastage. In response to this problem, the introduction of the double shaft coconut shredder promises a revolutionary solution, offering efficient and sustainable coconut waste management. Conclusion The introduction of the double shaft coconut shredder marks a significant advancement in coconut waste management technology. With its efficient shredding capabilities, robust construction, and versatility, the shredder offers a sustainable solution for processing coconut husks and other coconut waste materials. By revolutionizing coconut waste management practices, the double shaft coconut shredder contributes to environmental conservation and resource optimization in coconut-producing regions worldwide.

Agriculture Paddy Separator

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering agriculture paddy separator. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

Cashew Husk Cleaning Machine

908,000 Per Piece