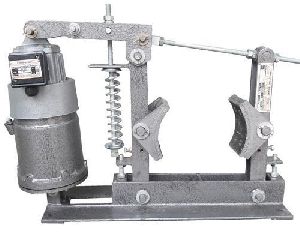

Electro Hydraulic Thruster Brake

11,500 - 11,500 Per Piece

Hydraulic Press Brakes

300,000 Per piece

1 Nos (MOQ)

We are manufacturer of Hydraulic Press Brake.

Best Deals from Hydraulic Brakes

hydraulic brake

20,350 Per Piece

Hydraulic Press Brake

750,000 Per Piece

1 Piece (MOQ)

hydraulic thruster brake

7,000 - 40,000 Per Piece

Electro Hydraulic Thruster Brake

Get Price Quote

electro hydraulic thrustor brake

Get Price Quote

10 Piece (MOQ)

Hydraulic Press Brakes Exporters Manufacturers Suppliers in Mumbai

100,000 - 500,000 Per piece

1 Piece (MOQ)

HYDRAULIC THRUSTER DISC BRAKES

Get Price Quote

Hydraulic Thruster Brakes: Our products are used extensively in the Mining, Ports, Steel and Power Generation industries on Conveyor drives, Stackers, Reclaimers, Ship Loaders, Ship-to-Shore, overhead and Gantry Cranes to name a few�

Hydraulic Press Brake

Get Price Quote

1 Piece (MOQ)

ANOX" Hydraulic Press Brakes are manufactured by adopting latest technology considering the requirements of Sheet Metal working industries for optimum production at minimum Maintenance. Both Cylinders mounted at the back side of Press Brake are Synchronised for parallelism. Heavy duty Steel construction is able to absorb heavy load. Following are Salient Features : Frame Frame made of MS Steel is of interlocked design. It supports Ram and Bed under permissible load condition. Ram Ram is a moving Part and holds V-Punch. It is machined for straightness and parallelism. It is guided on accurately machined Slides. Bed Bed supports V-Block and is grinded accurately. Bed is bolted to lower beam for easy change. Cylinders Two Cylinders are mounted at the back side of the Machine. Both Cylinders are Synchronised for parallelism by providing Mechanical link connected with levers. Tilting Arrangement It provides parallelism between Ram and Bed. Lubrication Each moving part is provided with lubrication through hand operated lubrication pump for smooth operation. Power Pack Hydraulic System consists of Hydraulic Components of international reputed make like RexRoth, Yuken, Polyhydron, etc… Standard Accessories Manual Back Guage Manual Lubrication Pump Electric Motor Control Panel With Foot Switch V-Block V-Punch Optional Accessories Automatic Lubrication System Motorised Back guage with DRO Goose Neck Punch & other Tooling Anti Deflection System

Sytco Hydraulic Brake

2,000 - 30,000 Per No

1 Piece (MOQ)

Hydraulic failsafe Disc Brakes

Get Price Quote

Hydraulic Sheet Bending Press Brake

450,000 Per

1 Piece (MOQ)

Numerical Control Hydraulic Press Brake

Get Price Quote

We offer high grade Numerical Control Hydraulic Press Brake that is ideal to be used for multiple bend jobs. The Numerical Control Hydraulic Press Brake that we offer is high in strength and is fabricated using superior quality material. Also, we are one of the reliable Manufacturers, Exporters, & Suppliers of Numerical Control Hydraulic Press Brake. Preferred For : Excellent performanceControlled back gauge axis x and ram axis yComplex bendingDepth mode programs and bend angleFastest stroke cyclesMagnetic press brake scale1 to 4 bends on every edgeGround and hardened ball screw along with linear motion bearingsBend program memory of 128 x 16Air bending by memorizing positions of stroke Automatic back gauge and degree position Availability : 2 Axes NC controllerNC strokeNC back guagePinch point back guage retraction NC value addition : Dedicated controller with LCD monochrome screen & numeric keypadManual,Auto & Program mode selection through screen128 programs X 16 bends per program can be storedStroke control and stroke counter on screenHighly Precise glass tube optical linear scale for accurate Y-axis positioningRepetitive accuracy within ± 0.03mmAlarm, Fault & status pages to detect the problemsPassword protected screen menus to safeguard program accessVarious drive Interface like two-speed motor, stepper motor or AC Servo MotorHardened ground Ball screw and linear motion bearing for better position accuracy and longer life. Optional Timer belt driveVarious drive Interface like two-speed Main Drive MotorElectrical control panel with selection of AUTO', 'INCH' & 'SINGLE CYCLE AUTO' mode operationsMovable work station with pair of foot switchPair of lifting linksPair of sheet supportFine stroke adjustment rod with limit switchManual back gauge with micro settingOne suitable five way die & Punch of EN-9** .(unhardened and ungrounded)Centralized lubrication system with flow control valves for adequate lubricationRam tilting arrangement on selected models Standard Accessories : Main Drive MotorSelection of 'AUTO' & 'MANUAL' mode through screenTwo axis dedicated controller with LCD monochrome screen & numeric keypad128 jobs X 16 bends program memoryMovable work station with pair of foot switchAC Servo motor with resolver for back gauge driveHardened & Grounded Ball screwLinear motion bearing on guide rodsHighly precise glass tube optical linear scale for accurate Y-axis positionPair of lifting linksPair of sheet supportOne suitable five way die & Punch of EN-9** (unhardened and ungrounded)Centralized lubrication system with flow control valves for adequate lubricationRam tilting arrangement on selected models Optional Accessories : AC servo drives for R-axis & Z-axis control of back gaugingAnti deflection unit (Manual / Motorized / Automatic)Sliding sheet support with Swing away stoppersHardened tools & special toolsHydraulic tool clampingPhoto electric fingers safety guardHigher throat depthAutomatic lubrication systemFast cycling models for high productivityFirst fill of hydraulic oil

Hydraulic Press Brake

Get Price Quote

These are heavy duty Hydraulic Press Brake machines available in a wide range of capacities ranging from 20 tons to 500 tons in pressure and job sheet size from 1500 mm to 5000 mm in length with 1.62mm to 20 mm in thickness. The machines are supplied complete with all standard accessories including the following: Main Drive Motor Electrical control panel with selection of AUTO, INCH and Single Cycle AUTO mode of operation Pair of foot switches Pair of lifting links Fine stroke adjustment rod with limit switches Front operated manual back gauge with fine setting knobs One suitable 5 way die and universal upper blade- segmented or full length Centralized lubrication system with hand pump Pair of sheet supports Bending chart Maintenance tool kit Comprehensive instruction & maintenance manual with CD Many optional accessories are offered such as: Motorized deflection compensation unit Ram tilting arrangement Hardened and ground tools & special toolings Motorized back gauge with DRO Sliding sheet supports with swing away stoppers for front gauging. Hydraulic tool clamping Photo electric finger safety guards We also offer NC and CNC Synchro Press Brakes. Kindly ask for details with your requirements.

CNC Hydraulic Press Brake

450,000 Per Set

WE are manufacturer of Hydraulic Press Brake machine and shearing machine all Models are available like Manual Hydraulic Press Brake, NC press brake, cnc press brake, hydraulic shearing machine, NC hydraulic shearing machine

Profi 28 CNC - Boschert

Get Price Quote

The BOSCHERT Profi 28 NC and Profi 28 CNC are precision hydraulic press brakes. The extremely compact and robust structure of these machines and the twin guides guarantee ram repeatability of 0.02mm. The Profi are designed to manufacture small parts and perfectly compliment your existing larger machines. By forming small parts on the Profi and larger parts your existing machines, plant productivity is greatly improved. Standard tooling is Amada style, with other systems available on request. Material stops are adjustable vertically and horizontally and have stop fingers with two faces each. With a maximum bending force of 28 tons, typical work could include parts up to 300mm long and 10mm thick.

electro hydraulic brake

8,000 Per Piece

imported hydraulic press brake

Get Price Quote

Electro Hydraulic Thruster Brakes

Get Price Quote

We are instrumental in the manufacturing and supplying of optimum quality Thruster Brake . These brakes are precisely manufactured in compliance with technical parameters using high quality metal and latest technologies. Appreciated for their simple functionality, rust resistance and hassle-free operation, offered brakes are demanded in textile, cable winding, rubber and food processing industries. Salient Features : This is a spring loaded normally ON Failsafe Brake Consists of Electro Hydraulic Thruster, Torque Spring and Liner riveted to Brake Shoes Works on 415 V AC, 3 Phase, 50 Hz supply Requires Transformer Oil to be filled in the thruster cylinder Function is to bring to stop, moving / rotating machinery like motor / gearbox Holds / stops the load in desired place Prevents jerk due to soft stop Maintenance free, robust design Details : Range - Drum diameter 100mm to 600mm Thruster Capacity (Kg) - 18, 34, 46, 68, 114 Torque Capacity - 6 Kgm to 580 Kgm Applications - All Material Handling and Lifting Equipments Hoisting - Electric wire rope Hoists and Crabs Cross travel and Long travel - EOT / Gantry / Goliath / Derrick Cranes Winches and Conveyors Lifts and Elevators