Hydraulic Test Rigs

Get Price Quote

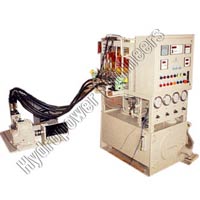

The speed can be connected to any load process. When pumping losses are relatively low, extra power can be generated and temporarily stored in the accumulator. However, when the losses are high, the load process can be supplied from the accumulator unit. Hydraulic Test Rigs are controlled by PC for high response speed of hydraulic system and speedy & precise evaluation of test results. Consists Of Pressure pump Several valvesAccumulator unit Used For Testing Automobile Component

hydraulic test rig

Get Price Quote

We are Test Rigs Exporters based in India Our Test Rigs are perfect for various experiments performed in chemical engineering laboratories or R&D units pertaining to various processes like distillation, absorption, heat & mass transfer, decantation etc. Besides this, we also offer Test Rigs for performance of falling film and packed towers with different packing for absorption process.

Best Deals from Hydraulic Test Rig

hydraulic test rig

Get Price Quote

As a respectable firm, headquartered in Ambala(India), we are making available top-of-the-line quality products in the market. Our warehouse is equipped with modern amenities and assists us completely in fulfilling urgent and voluminous requirements of the clients on a timely basis. Features Precision engineered Smooth operation User-friendly

hydraulic test rig

Get Price Quote

Fully digital control 58101525 kN force rating actuators 2550100 mm actuator stroke options Works out of 1Ǿ 230VAC or 3Ǿ 415VAC Next generation DSP based 32 bit multi station, multi-channel operation with simultaneous and accurate control of each actuator 24 kHz data acqusition & 24 kHz servo loop control 32 Bit data acquisition Power packs rating from 11 LPM to 500LPM

Hydraulic Pump Test Rig

Get Price Quote

Before making the final dispatch, our entire lot is carefully stored in our capacious warehouse under the administration of experts. Thus, there are minimal chances of defects at buyer's end.For the utmost convenience of our customers, we ensure that the transaction is done only under the stern supervision of experts and professionals. This makes our payment procedures more secured and transparent. Features : Precision made Industrial application User-friendly

Hydraulic Ram Test Setup

Get Price Quote

Product Code: EKE 2256The Set-up is designed to study the Hydraulic Ram. Hydraulic RAM is used for pump little quantity of water to high head from a large quantity of water available at low head. It works on a principle of water hammer stating that “When flowing water is suddenly stopped in a long pipe a pressure wave travels along the pipe creating an effect of water hammer”. The Set-up consists of a pipe section fitted with a pulse valve and non-return valve, a supply reservoir on a stand which is connected to an overhead tank, an air vessel above the valve chamber smoothes cyclic fluctuations from the Ram delivery. Different pressure may be applied to the pulse valve to change the closing pressure and hence the operating characteristic. The flow rate of useful and waste water is measured using measuring tank and stop watch provided. Pressure and Vacuum Gauge are connected on delivery and suction side for the purpose of measurement.Experiment To find out discharge of useful water and waste water. To find out the efficiency of the Hydraulic RAM Features: Closed loop water circulation Compact & stand alone set-up MS Excel sample calculation program on demand Stainless Steel tanks and wetted parts Superb painted structure Simple to Operate & Maintain Utilities Required Electric Supply:- Provide 230 +/- 10 VAC, 50 Hz, Single Phase Electric Supply with proper earthing. (Neutral – Earth voltage less than 5 VAC) 5 A, three pin socket with switch for pump. Water Supply: Tap water connection ½ “ BSP Distilled water @ 90 Ltrs. (Optional) Technical Specifications: Product : Hydraulic RAM RAM : Size 50 x 15 mm, Supply Head 2.5m, Delivery Head 10 m (max.) Air Vessel : Suitable Capacity MOC SS Delivery Line : For RAM, Dia 50 mm Length 6 m. Pump : Capacity 1 HP, Crompton / Sharp / Hero make Supply Tank : Capacity 150 Ltrs. Overhead Tank : Capacity 100 Ltrs. Measuring Tank : Suitable Capacity one each for useful and waste MOC SS fitted (2 Nos.) with Piezometer Tube & Scale Piping : GI / PVC Stop Watch : Electronic Pressure Gauge : Bourdon Type Control Panel : Comprises of Standard make On/Off Switch, Mains Indicator etc. Tanks will be made of Stainless Steel. The whole Set-up is well designed and arranged in a good quality painted structure.

Hydraulic Wheel Turbine Test Rig

Get Price Quote

Clients can stay assured for the products that we offer, as they will remain damage free. For this, we make use of premium packaging material for wrapping them. Buyers can stay rest assured about the quality of our products as we check each and every product at diverse stages. Range: Pelton Wheel Turbine Test Rig (Capacity : 1 Kw) lKaplan Turbine Test Rig (Capacity : 1 Kw) Steam Turbine Test Rig Centrifugal Pump Test Rig (Three Speed Cone Pulley) Gear Pump Test Rig Submersible Pump Test Rig Hydraulic Ram (Closed Circuit) Hydraulic Tilting Flume / Open Channel - 4 Meter Hydraulic Tilting Flume / Open Channel - 6 Meter Hydraulic Tilting Flume / Open Channel - 10 Meter Experiment Pneumatic Apparatus Hydraulic Tilting Flume / Open Channel - 10 Meter Experiment Hydraulic Apparatus Pelton Wheel Turbine Test Rig (Capacity : 3.7 Kw) Francis Turbine Test Rig (Capacity : 3.7 Kw) Kaplan Turbine Test Rig (Capacity : 3.7 Kw) Centrifugal Pump Test Rig (Constant Speed) Reciprocating Single Stage Pump Test Rig Jet Pump Test Rig Cavitations Test Rig Hydraulic Tilting Flume / Open Channel - 8 Fits Hydraulic Tilting Flume / Open Channel - 5 Meter Hydraulic Tilting Flume / Open Channel - 8 Meter Wind Tunnel Experiment Pneumatic Apparatus Wind Tunnel Hydraulic Ram Model Turbine & Pumps Models : Centrifugal Pump Deep Well Turbine Pump Francis Turbine Model Kaplan Turbine Model Steam Turbine Model Reciprocating Pump Jet Pump. Submersible Pump Pelton Turbine Model De-level Turbine Model lHydraulic Ram Model

Hydraulic Compression Test Rig

250,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Ram Test Rig

Get Price Quote

We offer hydraulic ram test rig. Hydraulic ram: hydraulic ram of size 50 x 15m to work against a delivery head up to 20m from a supply head of 2.5metres to discharge about 250lph at 10m head. Supply tank: m.s powder coatingm.s frp linings.s unit tank of suitable size with over flow arrangement for supply of water at constant head of 2.5 meters. Supply & delivery pipings: supply pipe of size 50mm & 6 meter length connecting supply tank & hydraulic ram and delivery pipe of ½ ” size to deliver useful water from hydraulic ram to measuring tank. Measuring tank: m.s powder coatingm.s. Frp lining s.s unit of suitable size provided with standard fittings for measuring of useful water. Notch tank: m.s. Unit with frp linings.s unit with a brass notch plate and hook gauge for measurement of waste water. Sump tank: m.s. Unit with frp linings.s unit of suitable size for independent circulation of water through the unit. Supply pump set: 0.5hp, single phase to supply water from the sump to the supply tank.

Hydraulic Ram Test Rig

140,000 Per Piece

10 Piece (MOQ)

Hydraulic Ram Test Setup

Get Price Quote

K Piece (MOQ)

We are offering Hydraulic Ram Test Setup. Description:- the set-up is designed to study the hydraulic ram. Hydraulic ram is used for pump little quantity of water to high head from a large quantity of water available at low head. It works on a principle of water hammer stating that “when flowing water is suddenly stopped in a long pipe a pressure wave travels along the pipe creating an effect of water hammer”. The set-up consists of a pipe section fitted with a pulse valve and non-return valve, a supply reservoir on a stand which is connected to an overhead tank, an air vessel above the valve chamber smoothes cyclic fluctuations from the ram delivery. Different pressure may be applied to the pulse valve to change the closing pressure and hence the operating characteristic. The flow rate of useful and waste water is measured using measuring tank and stop watch provided. Pressure and vacuum gauge are connected on delivery and suction side for the purpose of measurement. experiment:- to find out discharge of useful water and waste water. to find out the efficiency of the hydraulic ram features:- closed loop water circulation compact & stand alone set-up ms excel sample calculation program on demand stainless steel tanks and wetted parts superb painted structure simple to operate & maintain utilities required:- electric supply: - provide 230 +/- 10 vac, 50 hz, single phase electric supply with proper earthing. (neutral – earth voltage less than 5 vac) 5 a, three pin socket with switch for pump. water supply: tap water connection ½ “ bsp distilled water @ 90 ltrs. (optional)

Hydraulic Ram Test Rig

Get Price Quote

Hydraulic Ram is used for pumping small quantity of water at high head, when large quantity of water

hydraulic cylinder test rig

Get Price Quote

We have advanced packaging systems available to make sure that the products are packed using the experts approved packaging stuff. We source the material from the leading vendors in the industry. We are instrumental in offering the exceptional assortment of product that are deigned and manufactured only after complete examination of the raw materials and inputs used.

hydraulic test rig

60,000 Per unit

Hydraulic Load Test Rig

Get Price Quote

We have hydraulic press ranging from 35 ton to 500 ton to test our cylinders and jacks. And hydraulic power pack for pressure testing upto 700 bars.

HYDRAULIC LIFT TEST RIG

Get Price Quote

Fully computerized testing m/c Hydraulic clampling of lift under test Recording of lift time , drop time , drop ,temperature , pressure , flow etc. Report generation for each sample. Offline filteration arrangement

Hydraulic drop Test Rig

Get Price Quote

The Hydraulic Drop Test Rig is an end of line system developed for the final testing of Hydraulic Lift System in Automotives. The system applies a standard load on hydraulic lift while continously monitoring the respective drop in it (mm) using precise sensors.

hydraulic test rig

Get Price Quote

The offered range of test rig for hydraulic valves is made utilizing high grade raw material such as brass, carbon steel, mild steel and duplex steel, sourced from trusted vendors of the market. Along with this, the offered range is known for handling pressure and flow of hydraulic fluid in hydraulic systems that run by electricity.

hydraulic test rig

Get Price Quote

In aviation, the dynamics of hydraulic engineering is not merely limited to the design and manufacture of an aircraft but also in the functioning of its various components and systems on the ground as well as in air. Thus whether taxiing on the runway or in a trajectory flight, the applications of this science in the form of cylinders, pumps, reservoirs, valves, flight and wing controls (ailerons, rudder and elevator) among others are most crucial. Keeping in view the safety aspects, all these systems call for highest level of monitoring and preventive maintenance for their upkeep in the course of their operation and utilities. This is enabled by the hydraulic test stand as an important diagnostic and analytical medium to ascertain the worthiness of each component. Also known as the test bench, it thoroughly tests the entire range of new, refurbished and even cannibalised parts and subassemblies. As such despite the advent of computers and automation based on assorted software for the ‘fly-by-wire’, there is an eternal demand for the services of hydraulic cartridge valves suppliers and test rigs, in India and around the world.

Hydraulic Ram Test Rig

Get Price Quote

The setup is designed to study the Hydraulic Ram. Hydraulic Ram is used for pump little quantity of water to high head from a large quantity of water available at low head. It works on a principle of water hammer stating that “when flowing water is suddenly stopped in a long pipe a pressure wave travels along the pipe creating an effect of water hammer”. Set up consists of a pipe section fitted with a pulse valve and non-return valve, a supply reservoir on a stand which is connected to an overhead tank, an air vessel above the valve chamber smoothes cyclic fluctuations from the Ram delivery. Different pressure may be applied to the pulse valve to change the closing pressure and hence the operating characteristic. The flow rate of useful and waste water is measured using measuring tank and stop watch provided. Pressure and Vacuum gauges are connected on delivery and suction side for the purpose of measurement Experiments To find out discharge of useful water and waste water. To find out the efficiency of the Hydraulic ram Utilities Required Electric supply Provide 230 +/- 10 VAC, 50 Hz, single phase electric supply with proper earthing. (Neutral – Earth voltage less than 5 VAC.), 5A, three pin socket with switch for pump. Water supply Tap water connection” BSP Distilled water @ 250 liters (optiona)