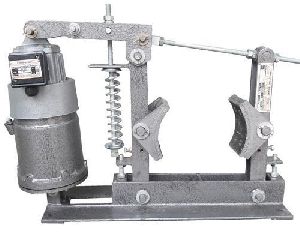

Electro Hydraulic Thruster Brake

11,500 - 11,500 Per Piece

hydraulic thruster brake

7,000 - 40,000 Per Piece

Best Deals from Hydraulic Thruster Brake

HYDRAULIC THRUSTER DISC BRAKES

Get Price Quote

Hydraulic Thruster Brakes: Our products are used extensively in the Mining, Ports, Steel and Power Generation industries on Conveyor drives, Stackers, Reclaimers, Ship Loaders, Ship-to-Shore, overhead and Gantry Cranes to name a few�

Electro Hydraulic Thruster Brake

Get Price Quote

Electro Hydraulic Thruster Brakes

Get Price Quote

ELECTRO-HYDRAULIC THRUSTER OPERATED DRUM BRAKES

Get Price Quote

Electro Hydraulic Thruster Brakes

Get Price Quote

We offer precision-engineered range of Electro Hydraulic Thruster Brakes. These brakes are ideally used to retard the speed of moving machinery. They are fabricated from the best grade raw materials and advanced components. Proper industrial rules and regulations are followed during the production of these brakes. We are a well-established Electro Hydraulic Thruster Brakes Manufacturer and Supplier from Delhi (India). The products delivered are thoroughly tested on various parameters to ensure their quality and durability. Working To stop the moving machinery accurately to the desired position the braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the bake drum and compressing of the spring is done by thruster. Features Gentle application & release of brake without jerks & shocks Compact unit Constant magnitude Self aligned movement Low power consumption Minimum maintenance Easy mounting and dismounting Assembly & FunctionA thruster shoe brake has a pair of cast iron shoes which are lined up with friction pads. The shoes are hinged on main arm and side arm of the brake, each of them have a hinge pin fitted in the base. They are connected to each other on top by a tie rod, which is hinged in the main arm and locked to the swivel block in the side arm, by a lock nut. A crank lever is hinged on the main arm and the other end is fixed to the top clevis of the thruster by a hinge pin. A brake spring is fixed on the main arm and is pre-loaded by a lock nut on the lever. The pre-tension in this spring decides the braking torque. The thruster is fitted on the base drum by a hinge pin. When the thruster is not energized, the brake shoes are pressed on the brake drum fitted on the drive motor shaft and hold it under the effect of braking force provided by the spring. In such condition, the brake is applied and the drum cannot rotates the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring. Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted. When the first lever reches the stop on the brake base member the brake lever at the thruster begins to move, releasing the brake drum.

Electro Hydraulic Thruster Brake

Get Price Quote

1 Piece (MOQ)

Thruster Brakes, which are offered through us, are hugely popular among clients for their mesmerizing features. The compatibility of Thruster Brakes with different application has supported us to claim the leading position of Thruster Brakes supplier. Features : Internationally well-known for their unmatched quality Modern technology Ensures the optimum quality production Uses : Retard the speed by a pre-stressed compression spring Mill duty thruster brakes Reliability and durability are some of the hallmarks of our thruster brakes

hydraulic thruster brake

8,000 Per Units

hydraulic thruster brakes

Get Price Quote

We are one of the leading names engaged in supplying an extensive array of hydraulic thruster brakes. We make sure that our payment procedures are protected and simple to use. Also, we facilitate our clients with methods like payment gateway, electronic funds transfer and various others.

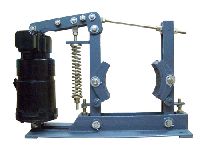

Electro Hydraulic Thruster Brakes

Get Price Quote

We are a celebrated Trader and Supplier of a wide assortment of Electro Hydraulic Thruster Brakes. These Electro Hydraulic Thruster Brakes are suitable for 440 Volts, 3 Phase A.C. We supply these Electro Hydraulic Thruster Brakes for a wide range of drum size from 100 mm to 600 mm diameter. The thruster rods are connected with the brake by means of an angle lever. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring, simulate easily, the brakes lever on the other side of the wheel is retroacted.

Thruster Hydraulic Brake

10,000 - 50,000 Per Nos

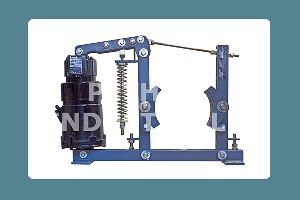

Electro Hydraulic Thruster Brakes

Get Price Quote

10 Pieces (MOQ)

POWERMECH supplies complete range of Electro Hydraulic Thruster Brakes suitable for EOT Crane, Hoists, Steel Mills, Rolling Mills, Elevators, Lifts, Cement Equipments, Heavy Engineering Equipments, Surface mining machinery such as excavators, stackers, transporting systems and combination devices. Thrusters are supplied in cast iron body or aluminium die cast body as required. Electro Hydraulic Thruster Brakes are supplied to suit various make of crane such as Amsak crane, Apex crane, Atlas crane, Avon hoist, Electromech crane, Esquare crane, Grip crane, INDEF crane, Intelle crane, K2 crane, Kone crane, MM engineers crane, Krans Crane, Magna crane, NE crane, SL crane, Sri Pranav crane, Sun crane, TAK crane, Unitech, Viralishanmuga crane, WMI crane, etc. Also, Electro Hydraulic Thruster Brakes of various make such as Speed-O-Controls, Speed-N-Systems, Strom kraft, Electromag are supplied. Applications: ♠ Suitable for Crane, Hoists, Steel Mills, Rolling Mills, Elevators, Lifts, Cement Equipments, Heavy Engineering Equipments, Surface mining machinery such as excavators, stackers, transporting systems and combination devices.♠ In addition, it has a wide industrial application: brake activation, coupling drive, valve drive, gate valve drive, shearing machine, etc.

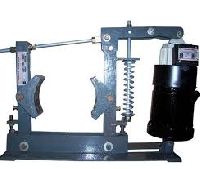

Electro Hydraulic Thruster Brakes

Get Price Quote

We are instrumental in the manufacturing and supplying of optimum quality Thruster Brake . These brakes are precisely manufactured in compliance with technical parameters using high quality metal and latest technologies. Appreciated for their simple functionality, rust resistance and hassle-free operation, offered brakes are demanded in textile, cable winding, rubber and food processing industries. Salient Features : This is a spring loaded normally ON Failsafe Brake Consists of Electro Hydraulic Thruster, Torque Spring and Liner riveted to Brake Shoes Works on 415 V AC, 3 Phase, 50 Hz supply Requires Transformer Oil to be filled in the thruster cylinder Function is to bring to stop, moving / rotating machinery like motor / gearbox Holds / stops the load in desired place Prevents jerk due to soft stop Maintenance free, robust design Details : Range - Drum diameter 100mm to 600mm Thruster Capacity (Kg) - 18, 34, 46, 68, 114 Torque Capacity - 6 Kgm to 580 Kgm Applications - All Material Handling and Lifting Equipments Hoisting - Electric wire rope Hoists and Crabs Cross travel and Long travel - EOT / Gantry / Goliath / Derrick Cranes Winches and Conveyors Lifts and Elevators

Electro Hydraulic Thruster Brakes

8,500 - 30,000 Per Nos

1 Set (MOQ)

THRUSTER 18 KG TO 68 KGTHRUSTER BRAKE MDT 100X18 TO MDT 500X68 AVAILABLE

hydraulic thruster brake

Get Price Quote

Electro-Hydraulic Thruster is a device which develops linear thrust (or force) required to operate the desired mechanism. The Thrusters are widely used to actuate thruster shoe brakes, commonly used in material handling equipments. Thrusters are available in various models.

hydraulic thruster brake

Get Price Quote

We are counted among the leading manufacturer & supplier of hydraulic thruster brake system for our precious clients. These are manufactured utilizing modern machines and highly advanced technology of the industry. These brakes are widely used in material handling machines & equipments. These brakes are tested by our experts in rigorous conditions to ensure quality & reliability.

hydraulic thruster brakes

11,000 Per Units

Electro Hydraulic Thruster Brake

Get Price Quote

hydraulic thruster brake

Get Price Quote

Application: STERLING Electro Hydraulic Thrustor is robust and dependable, possessing the stamina needed for the toughest duty conditions imposed by unattended drives in any industry. Because of its extra-ordinary versatility it has wide applications in electrically driven Hoists, Cranes, Elevators, Ropeways, Flap Valves, Guillotine Machines, Conveyors, Steel Mills, etc.