Industrial Hydrogenator

190,000 Per Piece

1 Piece (MOQ)

hydrogenators

130,000 Per Piece

1 Piece(s) (MOQ)

Hydrogenators are specially designed for various gas-liquid reactions. These vessels are built for longer life and to withstand constantly varying temperatures and pressure due to internal reaction condition. These gas induction reactors are fitted with specially designed agitator which creates very high gas-liquid contact area by recirculation of headspace gases, leading to superior mass transfer rates. Agitator is available with two sealing options such as mechanical seal & magnetic drive. Manufacture as per client’s requirement and specifications. Material of Construction Offered in Stainless Steel 304, 304 L, 316, 316 L, 317 L, 904 L or Mild Steel, Carbon Steel material or special grade as inquired buy Client. Capacity Available in the ranging form 50 Litres to 30,000 Litres. Agitator design to suit the reactants viscosity and density. Stirrer Types: Anchor shaft, propeller, paddle, turbine will be available.

Best Deals from Hydrogenator

hydrogenator

Get Price Quote

We hold expertise in manufacturing, supplying and exporting the Hydrogenator. We also offer Coded Gas Liquid Reactors and Hydrogenator having efficient impellers and agitators for gas liquid reactions. Through our designs, we ensure that during rotation of the impeller, a vacuum is created at the tip due to Venturi action. This vacuum overcomes the liquid head. Fresh or unreacted gases from the vessel upper crest re-circulate into the liquid/slurry through the hollow shaft. Higher gas flow rates and finer bubbles sizes impart a very high gas-liquid interfacial area. A unique flow pattern provides desired movement of the catalyst and excellent contact of the gases with the catalyst or solids. The impellers of Hydrogenator are suitable for reactions like Hydrogenation Chlorination Oxidation Ammonolusis Ethoxylation Carbonation Phosgenation Bromination Sulphonation Flurorination

hydrogenator

Get Price Quote

Hydrogenator offered by us utilizes a unique self gas inducing type multiple impeller system. The gas in the head space is induced inside the liquid by creating vortex due to top axial flow impellers (high solidity ratio hydrofoil impeller) and narrow baffles in that region. The feed gas being sparged through a sparger at bottom and the head space gas brought down by vortexing are, dispersed in fine bubble form by a radial hydrofoil impeller (hollow parabolic blade) installed at bottom.

shaker hydrogenator

Get Price Quote

Used mainly for synthesizing or modifying organic compounds by catalytic hydrogenation. Used to study catalyst activity. Available from 100 ml to 2 liters capacity in glass & metal interchangeable vessels. Maximum pressure of 20 bar (300 psi) for metal vessel & 3 bar (45 psi) for glass vessel Charging, operating etc. is very simple, also vigorous mixing reduces the reaction time considerably. Very small & compact system without gland hence requires minimum spares & maintenance. Very economical considering the interchangeability of different capacity vessels in one unit.

hydrogenator

Get Price Quote

Hydrogenated vessel is produced by the addition of Hydrogen gas to castor oil in the presence of nickel catalyst" This is known as hydrogenation process. Special Features: Porgrammable Functions SCADA Control Fully Automatic Optional Cooling System Available Direct Indirect types Available Easy Controls High Safety

hydrogenator

Get Price Quote

From Hyderabad, we are the notable Manufacturer and Supplier of the top-notch Hydrogenator across the country. Engineered as per the industry standards, these Hydrogenators are reckoned for their simple operations with high yield. By using durable material and advanced technology, we lift up the quality of these Hydrogenators. Avail the Hydrogenator from us in different specifications, at affordable prices. Also, we address to bulk queries.

Gas Hydrogenators

Get Price Quote

We offer the hydrogenator (gas induction type) as below, hydrogenator (gas induction type) salient features :- • uniform suspension of solid catalyst* • vigorous gas -solid -liquid mixing • very large gas-liquid interfacial contact area • enhanced gas-liquid mass transfer rates • low power consumption low batch time • very high heat transfer coefficients • suitable for hydrogenation, animation, aminolysis, oxidation • pressure upto 75 kgcm2 • very economical for more details please contact us .

hydrogenators

Get Price Quote

we specialize in designing and supplying coded Gas Liquid Reactors and Hydrogenators with highly efficient impellers and overall agitators for gas liquid reactions in aggressive services. Our impellers are ideal for reactions such as: Hydrogenation Chlorination Bromination Oxidation Ammonolusis Sulphonation Ethoxylation Carbonation Flurorination Phosgenation Through our designs, we ensure that during rotation of the impeller, a vacuum is created at the tip due to Venturi action. This vacuum overcomes the liquid head. Fresh or unreacted gases from the vessel upper crest re-circulate into the liquid/slurry through the hollow shaft.Higher gas flow rates and finer bubbles sizes impart a very high gas-liquid interfacial area. A unique flow pattern provides desired movement of the catalyst and excellent contact of the gases with the catalyst or solids.

Hydrogenation

Get Price Quote

We offer Hydrogenation.

hydrogenators

Get Price Quote

At Dipesh Engineering Works, we specialize in designing and supplying coded Hydrogenators with highly efficient impellers and overall agitators for gas liquid reactions in aggressive services. Our impellers are ideal for reaction such as: Hydrogenation, Oxidation, Ethoxylation, Phosgenation, Chlorination, Ammonolusis,Carbonation, Bromination, Sulphonation & Fluorination. Advantages: Through our designs, we ensure that during rotation of the impeller, a vacuum is created at the tip due to venturi action. This vacuum overcomes the liquid heat. Fresh or unreacted gases from the vessel upper crest re-circulate into the liquid/slurry through the hollow shaft. Higher gas flow rates and finer bubbles sizes impart a very high gas-liquid interfacial area. A unique flow pattern provides desired movement of the catalyst and excellent contact of the gases with the catalyst or solids Advantages: Through our designs, we ensure that during rotation of the impeller, a vacuum is created at the tip due to venturi action. This vacuum overcomes the liquid heat. Fresh or unreacted gases from the vessel upper crest re-circulate into the liquid/slurry through the hollow shaft. Higher gas flow rates and finer bubbles sizes impart a very high gas-liquid interfacial area. A unique flow pattern provides desired movement of the catalyst and excellent contact of the gases with the catalyst or solids. Client: M/s. Jubilant Organosys Ltd. Material of Construction: SA240Gr.316 Third Party Inspection : LRA Specialty :- A 5 KL Working Capacity SS316 Hydrogenator, having specially designed Gas Recirculation Agitator with Dual Internal Cooling coil with Jacket on the Vessel. Coupled with high pressure in the Vessel along with Agitator rotating at very high speeds (approx. 300 rpm), setting up mechanical sealing arrangement was the biggest challenge in the design and the manufacturing of the Vessel. In consultation with the seal manufacturer in India, we designed a unique in-house double mechanical seal with a forced lubrication system to withstand high pressure and temperature. This Eqpt Lived to the best Standards including Service support and we have supplied two more in last two years.

Hydrogenation

Get Price Quote

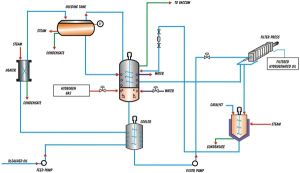

Hydrogenation which is also called fat modification is unique 3 phase process system: solid (nickel catalyst), liquid (oil) and gas (hydrogen). Further a selective reaction, by bringing gas - hydrogen, liquid - oil to the solid - ni catalyst and this technological concept formalized an engineering design. Muez-hest offers hydrogenation fat modification plant, which has several benefits. For industrial hardening we provide highly effective non selective hydrogenation process especially made for different application.

Industrial Hydrogenator

Get Price Quote

hydrogenator

Get Price Quote

We are an unmatched manufacturer & supplier of sophisticated Hydrogenator. Uniquely designed, our Hydrogenator meets all the tough norms related to Catalytic Hydrogenation needs. Economically available, we have an exhaustive range of Hydrogenator of numerous specifications such as Stainless Steel Hydrogenator and many others as well. Especially designed, our unique Stainless Steel Hydrogenator has led us to achieve top slot among the prominent Stainless Steel Hydrogenator Manufacturers in India.

hydrogenator

Get Price Quote

In the gas induction reactor the hollow agitator pumps the gas from head space to lowest part of the reactor vessel. The impelers vigorously disperse these gases into the reactor bottom. The gas bubbles react with the liquid & slurry as they rise. The unreacted gases are reinduced into the liquid through hollow shaft.

hydrogenators

Get Price Quote

hydrogenators, Agitators, Autoclaves, columns, Dryers, Evaporators

hydrogenator

Get Price Quote

hydrogenator, Laboratory Mill, Powder Sampler, lab homogeniser

hydrogenator

Get Price Quote

hydrogenator, Engineering Equipment, Dryers, vacuum equipment

hydrogenators

Get Price Quote

hydrogenators, Sulphuric Acid Plant, crystallizers, industrial fermenter

hydrogenators

Get Price Quote

hydrogenators, antrasite filter, Storage Vessels, Distillation Columns

Induced Draft Impeller Hollow Shaft Hydrogenator

Get Price Quote

Induced Draft Impeller Hollow Shaft Hydrogenator, Industrial Products

hydrogenators

Get Price Quote

hydrogenators, Filter, Autoclaves, Pressure Vessels, Ointment Plant

hydrogenator

Get Price Quote

hydrogenator, REACTOR, Receiver, Leaf Filter

hydrogenators

Get Price Quote

hydrogenators

hydrogenator

Get Price Quote

hydrogenator, Chemical Reactors, Heat Exchangers

hydrogenators

Get Price Quote

Gas-liquid reactions are very common in the chemical process industry and contribute to more than 30% of all the chemical commercial reactions. There are several commercially important reactions where the gas phase is pure/explosive/toxic. In all these cases the gas phase is expensive and complete utilization of the solute gas is desired. When gas is introduced into the liquid, it has a certain residence time after which it leaves the liquid phase and is lost to the atmosphere. To prevent this, there are often recovery devices attached in series with gas-liquid contactors. However, this requires the additional cost of installation of recovery devices and operating costs from recovering, pumping and compressing of recovered gas. The problem of retaining gas within the reactor has been achieved in the recently developed novel reactor design. It uses the self-induction principle for impellers. This reduces batch time, enhances reaction kinetics also contributes to reducing catalyst consumption. Energy-efficient impeller designs have been developed for gas induction and gas dispersion. It is also efficient for gas-liquid-solid three-phase reactions. The solid phase may be a catalyst or undergo a chemical reaction. This gas-liquid induction reactor (hydrogenator) is manufactured by acme process systems and finds application in a variety of industrial applications.

hydrogenators

Get Price Quote

hydrogenators

hydrogenator

Get Price Quote

hydrogenator, Pressure Vessels, Tanks, Heat Exchangers, Condensers

hydrogenators

Get Price Quote

hydrogenators, chemical process plants, Industrial Machinery

hydrogenator

Get Price Quote

hydrogenator, Crucible Furnace, Humidifier, Vacuum Pump Oil Sealed