Online Induction Sealing Machine

Get Price Quote

1 piece (MOQ)

Automatic Induction Cap Sealing Machine

60,000 Per piece

1 Piece (MOQ)

Best Deals from Induction Cap Sealing Machine

Induction Cap Sealing Machine

11,500 Per Piece

Induction cap sealing machine is a non contact process machine where in the seal is applied to the opening of the container. This is a leak proof seal and cannot be tampered with. It enhances the products shelf life as it makes the container airtight. Sealing head dimensions and heights are adjustable as per the container.

Automatic Induction Cap Sealing Machine

Get Price Quote

1 Piece (MOQ)

Automatic Induction Cap Sealing Machine The Automatic Induction Cap Sealing Machine consists of a main structure with a water-cooled unit, product transmission belt, foil sealing head, height adjustment system, electrical panel & PLC. Key Features:- The Induction cap sealing machine has been developed especially with a view to meet exact needs of the packaging industry. Our online model features wide output power range, high efficiency and microprocessor controls. This equipment can seal cap sizes of 20 mm-75 mm and 60 mm-120 mm dia. The features of the machine are enclosed herewith; Compact all-in-one design: Easily Movable: The machine is mounted on a wheel based water-cooling unit which provides mobility. Easy for line relocation. Single Body, “ON CONVEYOR” mounting system. Front panel with easy to use membrane switches. Coil movement Standard: 300 mm. Special: As required by the customer. Conveyor Stop System: The conveyor stops in predefined condition of Sealing Off. Over Load Protection & ALARMS Over Voltage Over Current Spike & Surge Over Temperature cut off No effect of voltage fluctuation

Induction Cap Sealing Machine

60,000 - 65,000 Per Piece

1 Piece (MOQ)

Induction Cap Sealing Machine

185,000 - 250,000 Per piece

1 piece (MOQ)

Induction Cap Sealing Machine

Get Price Quote

As a reliable name in the industry, we offer only quality-approved products to the clients. Thus, we make use of only excellent quality raw materials obtained from trusted sources. With our years of experience and expertise, we strive to make available high quality Induction Cap Sealing Machine at competitively low prices.

Single Phase Induction Cap Sealing Machine

275,000 Per Piece

1 Piece (MOQ)

Semi Automatic Induction Cap Sealing Machine

16,500 - 22,500 Per Piece

1 Piece (MOQ)

Our quality-driven Semi-Automatic Induction Cap Sealing Machine is used for hermetically sealing the Plastic & Glass bottle caps with aluminum foils. This makes the bottles leak-proof & tamper-evident and offers extended shelf life. Induction sealers are widely used in numerous industries. Salient Features Water not required 100% air cooled Designed to seala wide range of closure diameters Versatile User friendly Application Cap sealing Industry Pharmaceutical Chemical Lubricant Cosmetic FMCG Food processing Beverages

Induction Cap Sealing Machine

Get Price Quote

Induction Cap Sealing Machine

Get Price Quote

This machine use for used for P.E, H.D.P.E, L.D.P.E, P.P, glass bottles, and other non-metallic container sealing applications.

Induction Cap Sealing Machine GMP Model

Get Price Quote

Automatic Online Induction Cap Sealing Machine

Get Price Quote

The Online Induction Cap Sealing Machine developed especially with a view to meet exact needs of the packaging industry. Our online model features wide output power range, high efficiency and microprocessor controls. This equipment can seal cap sizes of 25mm-80mm. FEATURES Easily Movable : The machine is mounted on a wheel based unit, which provides added Mobility. Easy for line relocation. Save Power : Latest Solid State semiconductor technology ensures reliability. It has More than 90% power conversion efficiency, so less power is required. Safety / Protection Alarms : Built in protection circuitry for Over Current/ Over Voltage/ Over Temperature. User Friendly : No tuning, no tools, just plug it into 230V Single phase mains power Supply and seal. Speed: 60-80 containers/minute. Safe, Reliable & Compact.

Induction Cap Sealing Machine

Get Price Quote

We are a prominent Manufacturer and Supplier of high quality Induction Cap Sealing Machine with enhanced service life. Easy to install and operate, Induction Cap Sealing Machine has anti corrosive body and excellent functioning. As per the client’s requirements, we can make available both semi auto and fully auto Induction Cap Sealing Machine. We are a preferable choice of our clients for our quality tested machine at reasonable price. We always deliver all orders on time.

Induction Cap Sealing Machine

Get Price Quote

Induction Cap-Sealing Machine ,available in compact sizes and minimizes the amount of free conveyor required to only 1.2m. The machine is provided with generator and special tunnel type head for high speed sealing mounted on a mobile frame with an internal water circulator ensuring superior functionality of the machine.

Automatic Induction Cap Sealing Machine

270,000 - 285,000 Per piece

1 Piece (MOQ)

Induction Cap Sealing Machine

7,800 Per Piece

1 Piece(s) (MOQ)

Automatic Induction Cap Sealing Machine

Get Price Quote

Salient Features: Total cGMP Model. Automatic speed control system. Minimum Effort: The wad is put in the cap by the manufacturers. Thus the filling line requires only the Induction Cap Sealing equipment to be installed. Indirect Heating: Induction heating allows heat sensitive products such as creams, petroleum product, pesticides etc. to be sealed faster and safely than direct heating which would normally spoil or catch fire. Elegantly matt finished body. Standard in quality & economical in price.

Induction Cap Sealing Machine

Get Price Quote

We are engrossed in manufacturing and supplying of Induction Cap Sealing Machine. We fabricate our Induction Cap Sealing Machine using premium grade metal in the supervision of expert professionals. We offer our Induction machine in various dimensions and specifications so as to suit the varied requirements of the buyers. Being a reputed firm, we are capable of processing small as well as bulk orders of the Cap Sealing Machine.

Induction Cap Sealing Machine

Get Price Quote

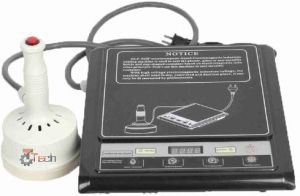

Induction cap sealing machine, The Arshad Fluxosealer™ BREZO P is a manual induction cap sealing machine that is used for laboratory andor low production volumes. This machine consists of a hand held induction sealing head placed over the capped bottle. The Machine starts sealing upon activation by a switch. The sealing time is preset using the Timer on the machine panel. Input Voltage: 230 Volts AC, Single Phase 50 Hertz. 7 Amperes. Sealing Speeds: 4 – 6 bottles per minute. Neck Diameters: 20mm - 83mm. MOC: Mild Steel Powder Coated Enclosure. Max. Power Consumption: 300 Watts. Footprint Dimensions: 400mm x 400mm x 200mm (lxbxh).