Industrial Fermentor

Get Price Quote

From our wide range of products, we offer optimum quality industrial fermenter. The entire range is designed using premium quality basic material and the latest technology by our experts. We offer the entire range in different sizes and various specifications, as per the ever-evolving needs of our prestigious clients. Mainly used in sugar mills, our offered range is rigorously tested by experts on well-defined parameters, in order to deliver a flawless range at our client's end. The Fermenters Manufactured By Us Can Be Supplied With Following Accessories With Various Type Of Agitators And Vortex Breaker With Manhole On Top /side With Tubular Legs / Conical Legs / Lugs With Light And Sight Glass With Level Indicator With Various Sensors For Monitoring Temperature / Pressure / Level With Variable Frequency Drives Features Supreme Functionality Less Maintenance Highly Efficient Application Pharmaceutical and food processing industries

Industrial bio fermenter

20,000,000 - 5,000,000,000,000 Per Set

1 Set (MOQ)

Bio Fermenter 30 liter to 30000 liter capacity Made of S.S. 316 /316 L with agitator assembly of s.s 316 /316 l shaft accuracy 0.02mm. with mechanical seal with s.s 304 jacket . With S.S.316/316L sparger specially designed for proper availability of Oxygen. with Geared motor. Manual and auto model. with SIP & CIP. Auto Model With auto control of all parameter .PLC based control panel with HMI and also Scada. Zero Contamination. GMP model. All Sensor controller of most reputed cos . Manufacturing since 2001..

Best Deals from Industrial Fermentor

Industrial Fermentor

Get Price Quote

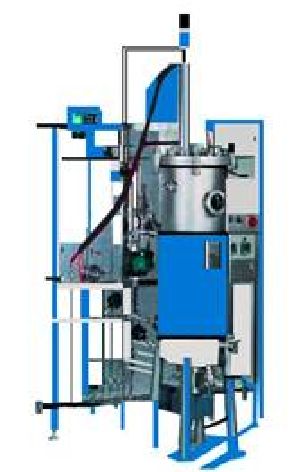

We are a famous name occupied with giving a broad combination of pilot scale and industrial sacle in-situ sterilizable fermenter. This fermenter is designed by using quality guaranteed parts under the direction of exceptionally talented experts. It is accessible with us in different models, design and other related details. Likewise, this range is inspected properly by our quality specialists upon different parameters of quality. Type =whole ss316l vessel with ss304 jacket in-situ sterilizable. Controls= auto temperature rpm ph do2 cascade control antifoam air flow auto sterilization through modular microcontroller plc&pid controls. Other probes for out gases etc available on demand. Drive =top driven and direct coupled motor with single double mechanical seal. Steam air filtration =0.22μm ptfe filter cartridge with ss316l housing plus 0.45μm prefilter with ss housing. Software =standard data acquisition software with rs-232-c serial port usb interface to communicate with pc for trends graphs tabular form into excel format. Optionally scada software available for computer controlled fermenter operation.

mother culture fermentor

195,000 Per Piece

1 Pieces (MOQ)

MFL Fermenting Unit

Get Price Quote

The Maturing / Fermenting Unit is a tank which allows milk to be heated and also cooled, with the aim in mind to pasteurize (heat) the product and control its fermentation (cool). The unit can be used to produce yoghurts of different types, fermented milks and sour cream. Additionally this very same equipment forms an integral part of the process to produce butter. Operating principle Production of yoghurt: after exiting the pasteurizer the milk is fed into the Maturing/Fermenting Unit. This heat treatment eliminates principally all the pathogenic flora. The contents are then cooled and the ferments or ‘starters’ are added.To make liquid yoghurt incubation is carried out in the Maturing unit with mixing and temperature control until the process of fermentation has finished. It is then cooled and packaged.To make firm-type yoghurt packaging is carried out before incubation. It is then placed in a heated store-room for maturing and then cooled afterwards in a refrigerated store-room. Butter making: the elaboration of butter starts with the cream obtained from the process of skimming or standardisation of the milk. The cream is cooled and stored in the Fermenting Unit in a similar way to that of yoghurt. Design and features Vertical closed unit in stainless steel AISI 316L o AISI 304.Double jacket for heating with water or steam.Cooling by iced water.Variable speed agitator for uniform mixing.Temperature control probe.Adjustable temperature.Level sensors.Air entrance with filter.Spray balls for CiP cleaning.Peephole with illumination for visual inspection.Man-hole for inspection and maintenance. Materials Parts in contact with the product AISI 316L and AISI 304Rest of materials AISI 304Gaskets in contact with the product EPDMInterior surface finish (product contact) Ra ≤ 0.8 μmOther exterior finishes Matte polished Options Filters for sterilization with steam.

Industrial Fermentor

Get Price Quote

Sturdy construction, Inner chamber made of 16gauge stainless steel, outer shell & steam jacket is also made from thick Stainless Steel. The boiler & outer shell is provided with air insulation. Lid is made of Stainless Steel & is tightened by screws& is provided with best quality joint less neoprene gasket to avoid any risk & trouble free operation, with port for temperature pH indication. Provided with stirrer along with heavy duty crompton motor. Fitted with water level indicator to indicate the water level inside the boiler. With pressure gauge, steam release cock, safety valves, spring loaded safety valves etc. Pressure in between 5 to 22P.s.i. Provided with drain valve to emptying the chamber. Provided with ISI mark heating elements, which are easily replaceable & heats the water to desired temperature & pressure. Pressure is indicated by pressure gauge, line air filter. Outer two jackets are provided with copper coil for water re-circulation with auto pressure cutoff device. With air compressor for aeration in fermentor. Capacity 100Liters 150Liters 200Liters

Industrial Fermentor

3,000,000 Per Set

1 Set(s) (MOQ)

Industrial fermentor of upto 50KL with full automation. ALso provides turnkey projects and project consultancy.

Industrial Fermentor

Get Price Quote

Our Fermentors are carefully designed with excellent finish and are reliable with good reproducibility. The fermentors are in SS 316 with proper piping rack and control panel. Designed with minimum footprint, the pilot fermentor system is mounted on movable skid you get optimized flexibility of operation. We offer fermentors / Bioreactors ranging from 3 liters to several KL capacities with fully automatic PLC/ SCADA Syst

Industrial Fermentor

Get Price Quote

Industrial Fermentor, HTAA- PR Enzymes, Dex- PR Enzymes

Industrial Fermentor

Get Price Quote

Industrial Fermentor, HEAVY DUTY ROTARY SHAKER, paint manufacturing machinery

Industrial Fermentor

Get Price Quote

Industrial Fermentor, Glass Pilot Plant, Hydro Extractor, distillation units

Industrial Fermentor

Get Price Quote

Industrial Fermentor, ethanol plants, Ultrafiltration System

Industrial Fermentor

Get Price Quote

Industrial Fermentor, Chemical Tanks, Reaction Vessels, Fermentation Tank

Industrial Fermentor

Get Price Quote

Industrial Fermentor, Fermenter Vessel, Conductivity Sensor

Industrial Fermentor

Get Price Quote

Industrial Fermentor, Water Quality Analysis Kit-8 Parameters