Ro Water Purifier Systems with Reverse Osmosis Filter

Get Price Quote

Contact us for immaculate-quality Ro Water Purifier Systems with Reverse Osmosis Filter! We procure these Ro Water Purifier Systems with Reverse Osmosis Filter from the vendors who comply with industry stated norms. Strict quality tests based on different parameters ensure that only defect-free Ro Water Purifier Systems with Reverse Osmosis Filter reach the buyers. Available at the nominal rates, these Ro Water Purifier Systems with Reverse Osmosis Filter are proven effective in decontaminating water from the biological contaminants, undesirable chemicals & suspended solids. Also, we address to bulk queries. Details :Water purification methods : Physical processes : filtration, sedimentation and distillation. Biological processes : sand filters, active carbon filters. Chemical processes : coagulation and flocculation, chlorination. Electromagnetic radiation : ultraviolet light. Capacity : 15/25/50/100 LPH Reverse Osmosis+UV design. 60/120/180/300/600/1200/2000/3000 LPH Ultra Violet Attributes : 20 Watts Philips UV Lamp 20" Filter Housing Activated Carbon Filter UV Sterilizer 05 micron to 01 micron filters Five stage Ro Water Purifier Systems with Reverse Osmosis Filter Fully auto on/off Water Cooler Connected(Optional) Reverse Osmosis + Ultra Violet Treated Water Suitable for : College Hostels Hospitals Hotels & Restaurants Public Places, etc.

Bag Filter System

Get Price Quote

Best Deals from Industrial Filtration Systems

Coolant Cutting Oil Purification System

425,000 Per Litre

1 piece (MOQ)

Activated Carbon Filters

Get Price Quote

20 Piece (MOQ)

Our Activated Carbon Filters are acclaimed for their make & quality. Owing to our exceptional automated warehouse, the human interference has decreased that help us to make on-time deliveries as well. With substantial storage space, the products are kept with utmost safety to circumvent loss during loading and unloading. Our team makes it possible to carry out online transactions, keeping the details confidential. Our payment procedures and the transactions we make are completely transparent and thus, clients can trust on us.

Activated Carbon Filter

Get Price Quote

SHIMMER Activated Carbon Filters are intended to remove free residual chlorine and toxic organic compounds from water like pesticides and heavy metal organic compounds. For removal of odour, organic matter and traces of oil, peat based activated carbon with larger pore size can be supplied on request. FEATURES Filters are compact and easy to install and maintain. The filters can tolerate any variation or shock loads in free residual chlorine unlike chemical dosing systems which require constant monitoring and adjustment of dosages. Pressure gauges at inlet and outlet are provided to measure pressure gauges across the unit. Filter backwash is carried out by reversal of flow. Applications: - The Activated Carbon filter is an ideal choice for all applications where a conventional sand filter is used. Raw Water Treatment Process. Drinking Water. Side Stream Filtration for cooling water. Filtration Process in Industries. Pre-Treatment for Membrane systems. Swimming Pool water Filtration. Filtration in Tertiary waste water treatment. Features Filters are compact and easy to install and maintain. The filters can tolerate any variation or shock loads in free residual chlorine unlike chemical dosing systems which require constant monitoring and adjustment of dosages. Pressure gauges at inlet and outlet are provided to measure pressure gauges across the unit. Filter backwash is carried out by reversal of flow. RANGE OF PRODUCT MODEL AVAILABILITY- Activated Carbon Filter is comprises of Mild Steel /MSRL/SS/FRP Pressure Vessel, Frontal piping wok with manual / Automatic - multi port valve/ butterfly valve / conventional valves for easy operation and control. Available from 1 m3/hr. to 100 m3/hr.

Microfiber Activated Carbon Filter

2,500 Per Piece

10 Piece (MOQ)

Activated Carbon Filter

Get Price Quote

1 Piece (MOQ)

Activated Carbon Filters (ACF) are used to remove odour, colour, free chlorine etc & improve the taste of the water. It is usually employed after the media filter & used for water & waste water treatment applications. Activated carbon of suitable lodine Value as per application is selected as the filter media.

Compact Paper Band Filter

Get Price Quote

We offer Compact Paper Band Filter that is fabricated for coolant filtration of fluids.

Self Cleaning Filter System

Get Price Quote

Granular Activated Carbon Cartridge Filter

300 Per Piece

10 Piece (MOQ)

Water Purifying Filter Systems

25,000 - 200,000 Per Unit

5 Piece (MOQ)

Activated Carbon Filter

Get Price Quote

Rely on us to buy the best in class Activated Carbon Filter; we are a notable Supplier in this domain. We stock our product for wholesale distribution and supply as we have state-of-the-art storage facility along with the most advanced inventory management system and upgraded machines. Features : Quality finish Great output Reasonable price

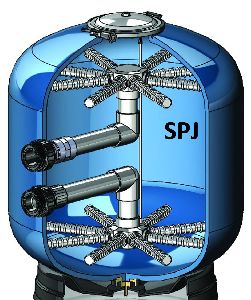

Swimming Pool Filter System

65,000 - 980,000 Per Set

1 Set (MOQ)

We are a manufacturer, supplier and exporter of swimming pool filteran system amd all related equipments of pool filter and other accessories.

Pressure Sand Filter System

Get Price Quote

1 Piece (MOQ)

Auto Scrapper Mechanism Filter System

300,000 - 2,000,000 Per Piece

1 Piece(s) (MOQ)

Centralised Coolant Filtration System

Get Price Quote

1 Piece (MOQ)

We are one of the leading Manufacturers, Exporters & Suppliers of exceptional Centralized Coolant Filtration System. The Coolant Filtration System is sternly fabricated in the high-tech manufacturing, designing unit that is equipped with the latest machines and technology. Staffed with a team of professionals; they keep a close coordination and check on the production stages. We make sure that the range is as per the set industrial norms.More about Centralised Coolant Filtration System : A Centralized Filtration System is basically a Common Filtration System for a group of machines. Hence a centralised filtration can cater to a small group of machines or the complete shop. It is generally a combination of various Coolant Filtration System products and accessories. A Centralized Filtration System is the most effective and efficient ideology in Coolant Filtration System and Cutting Oil Filtration System. A Centralized Filtration System has huge benefits over a Individual Filtration System. Below is the list of all the reasons why you should opt for a Centralized Filtration System in comparison to a stand alone filtration system. Saving in Electrical power / Connected Load :A stand alone filtration system has separate pumps for bed flushing , tool flushing , spindle cooling etc. Hence the connected load for each machine is very high. All these requirements can be catered using a single pressure fluid line : A Centralized Filtration System has common pumps which pressurize a grid of piping which runs in your shop. Tapping is taken from the same pipe line for various requirements. This reduces the number of pumps required. In a Centralized Filtration System a pump with larger flow capacity is used. These pumps have higher efficiency compared to smaller capacity pumps used in stand alone system. Hence the power required to pump the total flow is much lower as compared to the sum total of power required of stand alone tanks. A total power reduction of 25% can be achieved. Additional facilities like a VFD ( variable frequency drive ) can also be easily incorporated to reduce the power consumption even further. Increase in Coolant life : A stand alone system has to kept near the machine. Hence it occupies a large shop floor area. In order to reduce the area some aspects of filtration are typically compromised. Smaller size means lesser through put time ( allowable time ) for filtration. The fluid has to pass through the filter faster. This increases the flow velocity which drastically reduces the filtration efficiency. Due to small size multiple stages of filtration is not possible which puts load on the finer filter reducing its efficiency. As the finer particles are not filtered properly, they start accumulating in the system. After a certain threshold level an operator is forced the coolant / cutting oil as the contamination starts affecting the surface of the job. Traditional it has been observed that a stand alone has to be cleaned after every 3-6 months. As the centralised system can be kept away and also outside the shop floor area, the size can be made suitable to provide sufficient through put time. Also a multi stage filtration and separation is provided. The increases the bath life drastically to 45-60 months. Increase utilisation of shop floor area : A stand alone system has to be placed near the machine and consumes valuable shop floor area. It takes almost the same space or more than the machine tool. This area if saved can be used for direct production activities increasing the productivity. Space also has to be provided for easy access and maintenance of these stand alone filtration systems. A Centralized Filtration System can be placed in non-productive area like utility hangers or even outside the shop. Hence you not only save on the foot print area of the stand alone filtration system but also the area kept vacant. Through our various projects we have seen a 25% saving in shop floor utilisation. This means you can increase your production by 25% in the same available shop floor area. Reduction in manpower cost : Huge manpower is required for the cleaning and maintenance of individual stand alone system. As each system has its multiple pumps , conveyors , filter units etc. Parameters like coolant concentration , pressure , temperature , filter media replacement has to done on each stand alone system Comparatively such activities are needed to be done at a single point of the Centralized Filtration System. Typically we have seen a 80% reduction in the manpower associated in these activities.

Paper Band Filtration System

Get Price Quote

The Filters and Chip Conveyors have been supplied to both indigenous and imported machines and are also used as original fitment by many machine tool builders. Our company has wide range of standard models to choose from and speciallarge conveyor systems can be designed and supplied as per the customer requirement and applications. We deal in the following products:

Ultra Filtration System

Get Price Quote

We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. We are a focused towards bringing forth exceptional array of products (Ultra Filtration System for industrial/commercial ) that are quality tested from the initial stages of manufacturing. Our quality inspectors inspect each and every element of the raw material with complete proficiency.

S.S 304 paper band filter paper

65,000 - 1,045,000 Per Piece

01 Piece(s) (MOQ)

Filter Bag Dust Collection System

20,000 Per Piece

5 Piece (MOQ)