Stainless Steel Double Semi Cartridge Seal

700 Per piece

50 piece (MOQ)

Maximum sealing safety is guaranteed by the design of this double semi cartridge seal. This basically eliminates the possibility of fluid or gas leaking out of pumps or mixers. It offers a degree of safety and emissions compliance with zero emissions that is not feasible with single seals. When blending a hazardous or lethal chemical, this double semi cartridge seal is crucial. Additionally, this mark is required in several nations for specific uses. Companies are using it more frequently now to satisfy strict environmental objectives or emissions standards.

Silicone Oil

Get Price Quote

1000 kg (MOQ)

Water Based Organosilicone Surfactant Defoaming Agent Agricultural Organic Silicone Oil Feature and advantages: Chemical name :dimethicone/silicone oil/silicone fluid/ polydimethylsiloxane/simethiconeCAS No.: 63148-62-9/9016-00-6/9006-65-9 .EINECE : 618-493-1 . 1. Smoothness & softness & hydrophobicity & good chemical stability & insulation property.2. High and low temperature resistance & high flash point.3. Low freezing point (it can be chronically used in the temperature from -50°C to +200 °C). 4. Small viscosity-temperature coefficicent & big compression ratio & low surface tension. Advantages Silicone oil is a colorless, odorless, non-toxic and non-irritating products, chemical stability, heat resistance, cold resistance, water repellency, lubricity, high refraction, storage stability and compatibility with commonly used cosmetic ingredients.Take On Heavy Loads, Beat the Heat and Cold, and Manage Severe-Duty Success Drive Away Downtime with Hard-Working Solutions for Heavy Industry When maintaining equipment for severe-duty, demanding operations, you require problem-solvers that perform well. You need solutions that deliver under heavy loads, at low and high speeds, when exposed to dust and abrasives, and in hot, cold and harsh environments. You work hard to eliminate non-scheduled downtime, improve energy efficiency and get more payback from your sizable equipment investment.We can help with experience, expertise and proven performance:Withstand harsh operating environments and reduce expensive downtime in the Metals Industry. Meet challenges from quarry to quality and optimize plant productivity in the Cement Industry. Output in the Mining Industry.Maintain asset reliability and systems performance in port and at sea in the Marine Industry.Adhesives and sealants from us can resist weathering, degradation, loss of bonding and sealing strength, and softening or cracking.Tell Us Your Needs. Discover Answers. Get the benefit of technology-driven solutions from us to meet equipment and maintenance challenges in Heavy Industry. We are ready to go to work for you with specialty products, collaborative problem-solving and customized services and support. PROPERTIES:1,Clear, colorless, odorless2,Non-Flammable3,High Damping action4,Low Temp stability5,High Temp Stability6,HS Code 39100.007,Little viscosity change at temperature 8,Excellent lubrication9,High oxidation resistance 10,High dielectric strength 11,High water repellency 12,High Shear resistance 13,Open and closed system bath fluid

Best Deals from Industrial Seals

Carbon Face Seals

Get Price Quote

We manufacture Carbon Face Seals which are used for water pump mechanical seals. Our carbon sealing face offers controlled hardness, close lapped surface and excellent resistance. The carbon seal faces also has a polished and finished surface and are ideal to be used as water pump seals and for all types of mechanical seals. We manufacture them as per customers drawings or samples. We have positioned ourselves in the midst of the most notable carbon mechanical seal face exporters from India.

Mechanical Seal Robin Type Double

450 Per Set

1 Set (MOQ)

PTFE Valve Seals

Get Price Quote

A PTFE Valve Seal is a product designed to make the functioning of valves more easy. These seal are made to fill in the ends of the valves so that the functioning can be more easy and efficient. We manufacture these keeping in mind the various conditions that Valve Seal may face especially in India. The variant and extreme climate the country has is kept in mind. We supply and export these in different sizes.

31mm Induction Sealing Wad

Get Price Quote

10000 pieces (MOQ)

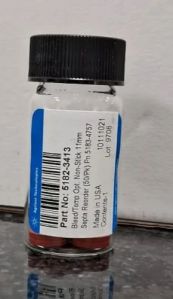

Agilent GC Septa

3,200 Per Piece

100 Piece (MOQ)

Double Cartridge Mechanical Seal

2,500 - 50,000 Per Piece

1 Piece (MOQ)

Double Cartridge Seal

25,000 Per Piece

10 Piece(s) (MOQ)

ApplicationApplied In Sealing High Corrosion Media, Alcohol Processing Industries, Pulp And Paper Industries, Petrochemical Plants, Nuclear Plants, Mixers, Steel Making Plants, Biochemistry, Petroleum Refineries, Oil Refineries, General Chemicals, Light Hydrocarbons, Foodstuff Processing, Chemical Processing, Pharmaceuticals, Power Generation, Main Oil Pipeline Pumps, Chemical Process Pumps , High Pressure Pumps, Water Injection Pumps, Boiler Feed Water Pumps, Sludge & Syrup Pumps, Vertical Pumps, Sewage Treatment Systems, Wastewater Treatment, Clinker Grinders, Paint, Abrasive Liquid In Grinding Mills And General Rotary Equipments.

Dowty Washer Seal

3 - 9,999 Per Piece

100000 Piece (MOQ)

Seal Flange

150 Per Piece

51 Piece (MOQ)

hydraulic u seals

Get Price Quote

Hydraulic Seals

Get Price Quote

1 Piece (MOQ)

We are recognized as one of prominent Hydraulic Seals Manufacturers in the global market. Our Hydraulic Seals are constructed from a wide range of materials such as polyurethane, rubber or PTFE. Herein, the usage of our Hydraulic Seals of specific construction is based upon operating conditions, pressure, fluid type, chemical and temperature compatibility, etc. Types Available : Piston seal Rod seals Wiper seal Propelled by : Hydraulic and pneumatic seals Availability : 500 Nos. Features : Robust construction High efficiency Durable Less wear and tear Competitive pricing Used in : Steel Industry Rubber Industry Defense Industry Machine Tools Industry Earthmoving Industry

PS40P Pusher Seals

Get Price Quote

10 Piece (MOQ)

Recommended Applications Process industry Oil and gas industry Refining technology Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Pulp and paper industry Water and waste water technology Mining industry Building services industry Food and beverage industry Shipbuilding Sugar industry Metal production and processing Materials Seal face: Silicon Carbide (Q1, Q2) Seat: Carbon graphite resin impregnated (B), Silicon carbide (Q1, Q2) Secondary seals: EPDM (E), FKM (V), FFKM (K) Springs: CrNiMo steel (G) Metal parts: CrNiMo steel (G)

BME143 Balanced Multi Spring Seal With O Ring

Get Price Quote

100 Piece (MOQ)

M.O.C of Secondary Seal According to Fluid & Temp. Various Hard & Soft Faces As Per Liquid. No need to maintain a step on Sleeve for balancing

Padlock Eco Seals

4 Per Piece

5000 Piece (MOQ)

Fluoroelastomer Parts

10 - 200,000 Per piece

1 piece (MOQ)

We Offer Fluoroelastomer Parts. Available in various grades based on requirement . Orings Gaskets Sealants and Packers Available .Competitive Pricing. Oil and Gas and Semi Conductor Application

Agitator Dry Running Mechanical Seals

65,000 Per Piece

10 Piece (MOQ)

Are you looking for agitator dry-running mechanical seals? J I Mech Seal and Engineering is a reliable manufacturer and supplier of these products. Agitator Dry Running Mixer Seal Simple and rugged drive design that can withstand shaft movement, vibration & deflection. This Seal design eliminates the need for auxiliary equipment for cooling & lubrication that is required for mixer application. Since there is no use of barrier fluid, thus eliminates the possibility of product contamination and can be used in high vacuum applications. These seals are used on top entry agitators for food and pharmaceutical industries where contamination of the media with any other liquid inside the agitator is not permissible. These seals do not require any external lubrication to the seal faces, hence these seals are known as dry-running seals. Choose to deal with us and get our products today.

Rubber Diaphragm

Get Price Quote

Rubber Oil Seal

Get Price Quote

1000 piece (MOQ)

Welcome to Our Spare Parts Supply Service for Power Plants At Laujir, we are dedicated to providing top-quality spare parts for a wide range of rotating equipment, specifically tailored to meet the needs of power plants. Our comprehensive inventory includes spare parts for steam turbines, gas turbines, high-speed turbo gearboxes, and other critical rotating equipment essential for the smooth operation of power generation facilities. Our Commitment to Quality and Reliability: With years of experience in the industry, we understand the critical role that spare parts play in maintaining the efficiency and reliability of power plants. That's why we have meticulously curated our inventory to ensure that every spare part meets the highest standards of quality and reliability. Wide Range of Spare Parts: Our inventory boasts a wide range of spare parts, including but not limited to: 1. Steam Turbines: Blades, nozzles, diaphragms, bearings, seals, valves, and control system components. 2. Gas Turbines: Combustion components, compressor and turbine blades, nozzles, bearings, seals, valves, and control system components. 3. High-Speed Turbo Gearboxes: Gears, bearings, seals, shafts, couplings, lubrication system components, and vibration monitoring equipment. 4. Other Rotating Equipment: We also offer spare parts for various other rotating equipment commonly found in power plants, such as generators, pumps, and compressors. Customized Solutions: We understand that every power plant is unique, with its own set of requirements and operational challenges. That's why we offer customized solutions to meet the specific needs of each power plant. Whether you require standard spare parts or specialized components designed for your equipment, we have the expertise and resources to deliver tailored solutions that fit your exact specifications. Reliable Supply Chain: We have established strong partnerships with leading manufacturers and suppliers in the industry, ensuring a reliable and efficient supply chain. Our streamlined procurement process and strategic inventory management practices enable us to promptly fulfill orders and minimize downtime for our customers. Technical Support and Expertise: Our team of experienced engineers and technical experts is dedicated to providing unparalleled support and expertise. Whether you need assistance with identifying the right spare parts for your equipment or require technical guidance during installation and maintenance, we are here to help. Customer Satisfaction Guaranteed: At Laujir, customer satisfaction is our top priority. We are committed to providing exceptional service, reliable products, and timely support to ensure that your power plant operates at peak performance. Contact Us Today: Experience the difference of working with a trusted partner for spare parts supply. Contact us today to discuss your requirements and learn how we can support your power plant operations with our comprehensive range of spare parts and services.

Wave Washer Shaft Seals

Get Price Quote

We are known Manufacturer and Supplier of Wave Washer Shaft Seals in Uttar Pradesh, India. The offered Wave Washer Shaft Seals are widely demanded in several industries like electrical, automobile and engineering industries. We can provide Wave Washer Shaft Seals in customized specifications like different diameters and dimensions as per client’s requirements. Description : Type HS-40WW series seals are wave washer spring seals. Main advantage of these seals are reduced length due to use of wave spring and work more efficiently in dirty applications as spring clogging does not occur.Details : Silicon carbide, Tungsten carbide, Stellite etc.

SIC BIA Fcace Silicon Carbide Seal

1,500 - 2,000 Per Piece

1 Piece (MOQ)

Wave Spring Balanced Mechanical Seal

1,500 - 3,000 Per Unit

5 Unit (MOQ)

Description: Cost-effective single component seal Bi-Directional Easy to repair and clean Face materials can be easily changed Single unwelded wave spring or multiple springs Built to DIN 24960 Retainer with pumping screw available

Bucket Seal

12 - 620 Per piece

1 Piece (MOQ)

aluminium foil wads

1,000 Per Kilogram

10 Kilogram (MOQ)

Rubber piston seals

10 - 20 Per piece

100 Piece (MOQ)

ME-34 Pusher Seal

1,500 - 6,000 Per Piece

1 Piece (MOQ)

Dam Gate Seals

1,200 - 1,600 Per Meter

100 Meter (MOQ)

Wre have Experience 10 year in Dam Gate Seal, Manufacturing, Compounding, testing, Installation and Replacement. We are manufacturing wide of range Flat Seal 2mm to 25mm thckl and Rubber Bulb tob, and Side Seal Dia 25mm to 50mm and Width 70mm to 200mm. We Manufacturing With PTFE Cladded, Brass Cladded and MS Cladded Bulb Seal as per IS 11855 Specification. A dam gate seal is a component used to provide a watertight seal between the gate and the dam structure in a water control or hydroelectric power generation system. The gate seal helps prevent water leakage and ensures the efficient operation of the dam. The key features and characteristics of a dam gate seal include: 1. Material: Dam gate seals are typically made of durable and resilient materials that can withstand the hydraulic forces, pressure differentials, and exposure to water. Common materials used include rubber compounds, such as natural rubber or synthetic elastomers like neoprene or EPDM (ethylene propylene diene monomer). 2. Design: The design of the gate seal depends on the specific requirements of the dam structure and the type of gate system used. The seal is typically custom-made or fabricated to fit the specific dimensions and shape of the gate and the sealing surfaces. 3. Watertightness: The primary function of a dam gate seal is to provide a watertight barrier between the gate and the dam structure. The seal is designed to minimize or eliminate water leakage around the gate, ensuring effective water control and preventing loss of water or potential structural damage. 4. Compression and resilience: Dam gate seals are designed to compress and create a tight seal when the gate is closed against the dam structure. The seal must have sufficient resilience to accommodate movement of the gate and changes in water pressure without compromising the seal integrity. 5. Durability and resistance: Dam gate seals are exposed to various environmental conditions, including water, sunlight, and temperature variations. They are designed to be resistant to UV degradation, water absorption, ozone, and other factors that can degrade the material over time. 6. Maintenance: Regular inspection and maintenance of the dam gate seal are necessary to ensure its proper functioning. This includes checking for signs of wear, damage, or deterioration and replacing the seal if necessary to maintain its effectiveness. The selection and design of a dam gate seal depend on factors such as the water pressure, gate size, gate type (e.g., sliding gate, radial gate, or crest gate), and specific project requirements. Engineering consultants or manufacturers specializing in dam gate systems can provide guidance and expertise in selecting the appropriate seal for a particular dam application. The application of a dam gate seal is primarily in dam and reservoir structures to provide a watertight seal between the gate and the dam body. The seal plays a crucial role in ensuring the proper operation, water control, and stability of the dam. Here are some key applications of dam gate seals: 1. Water Leakage Prevention: The primary function of a dam gate seal is to prevent water leakage through the gate when it is closed. It forms a watertight barrier between the gate and the surrounding dam structure, ensuring that water is effectively contained within the reservoir and doesn't seep through the gate and cause uncontrolled flow or erosion. 2. Water Level Control: Dam gate seals are essential for maintaining precise water levels in the reservoir. When the gate is closed and properly sealed, the seal helps to regulate and control the release of water from the reservoir. This allows for efficient water management, flood control, and water supply distribution downstream. 3. Structural Stability: Dam gate seals contribute to the overall structural stability and integrity of the dam. By providing a secure seal between the gate and the dam, they help distribute water pressure evenly, redu

Single Spring Mechanical Seal

Get Price Quote

1 Piece (MOQ)

MSOP/C 160 Multi Spring Out Of Product Cartridge Seal

Get Price Quote

1 Piece (MOQ)

Multi Spring Out Of Product Cartridge Seal MSOP/C 160 Series is a multi spring cartridge construction factory assembled slide on seal specially designed and developed for slurry application. The springs are protected from the media by means of dynamic O ring. This seal requires tightening of stuffing box studs, nuts and detaching of location plate before starting the equipment. No dimensional measurement are to be done at site. Seal can be easily installed by a unskilled person. Seal Components/Face: Carbon / Ceramic Carbon / Silicon Carbide Silicon Carbide / Silicon Carbide Tungsten Carbide / Tungsten Carbide Secondary Seal : Elastomers Metal Parts: SS304, SS316, Hastelloy-C Seal Characteristics: Single Acting Balanced Springs are Outside the Media Independent of Direction of Rotation Stable Drive-pins/Lugs No Shaft Fretting