Plastic Injection Moulding Services

Get Price Quote

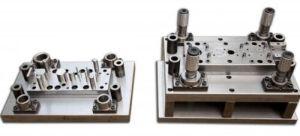

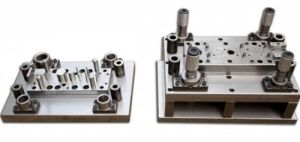

Process Overview – Injection molding is a manufacturing process in which molten plastic is injected into a mold which is made up of steel or aluminum. Principally it is like a die casting process used for making metal parts. The semi-molten plastic is injected into a feeding system and traversed to the mold before passing through feed, transition, and metering section. The Injection molding process cycle consist of six main stages : Closing of mold – When the mold is closed the injection molding cycle timer begins Injection - Heated plastic is injected into the mould. As the melt enters the mould, the displaced air escapes through vents in the injection pins and along the parting line. A good runner, gate and vent design are important to ensure the mould is properly filled. Cooling - Once the mould is filled the part is allowed to cool for the exact amount of time needed to harden the material. Cooling time is dependent on the type of resin used and the thickness of the part. Plasticizing the resin - While the part cools, the barrel screw retracts and draws new plastic resin into the barrel from the material hopper. The heater bands maintain the needed barrel temperature for the type of resin being used. Ejection - The mould opens, and the ejector rod moves the ejector pins forward. The part falls and is captured in a bin located below the mould. Removing the runner – Runners and gates are removed from the original part. Runners are also ground and recycled to reduce costs and environmental impact. Capabilities Integrated sequential manufacturing process under one roof i.e., Simulation -> Tool designing and manufacturing -> Prototype -> Mass production Tool room equipped with VMC’s and CNC’s for manufacturing of die and molds Prototype to high volume production of up to millions of parts per year based on part configuration Manufacturing of parts wide variety of materials such as ABS, LDPE, HDPE, Nylon, PC etc. Manufacturing of molds for up to 3000 Ton molding machine Provide different type of finish to molded part based on customer requirement CMM inspection for part validation and approval In-house lab tests carried out for raw material verification at production site, certified to international standards Defect analysis of plastic molded parts as per international standards Customer appointed third party inspection and verification allowed Manufacturing facility certified to IATF 16949 and ISO 13485 Quality Management System Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation Industry 4.0 integrated manufacturing facilities Application and Benefits Injection molded parts have vast application in consumer and commercial products which are used by us in our daily lives. Few commonly known parts include : Automotive parts – Dashboards, bumpers, grills Electronic components – Connectors, enclosures, protective sleeving Medical devices – Syringes, valves, dishes Consumer plastics – Mobile covers, bottles, toys Furniture – Seat covers, cushions, chairs Few important benefits of plastic injection molding are : Highly efficient mass production Low production cost Manufacturing of complex and intricate parts Enhanced material strength Flexibility of material and color selection Reduced material wastage

Injection Mould Designing Service

Get Price Quote

Multi-Tech Industries is one of the dependable service providers from Kolkata (West Bengal) that offers one of a kind injection mold designing service to fulfill the needs of injection molding products manufacturers. Right from the necessary qualifications to required facilities, we have everything that facilitates us to prepare injection mold designs with precision and competitiveness. We can prepare injection mold designs for almost every kind of product that could be manufactured with injection molding technology.

Looking for Injection Mold Designing Service Providers

Injection Mold Designing Services

Get Price Quote

1 Piece (MOQ)

Are you looking for a company that can provide you with the best quality injection mold designing services? If yes, then we at Gajjar Technoplast can be of great help to you.Our highly qualified, skilled and experienced professionals use the latest technological pieces of equipment in order to produce and design identical items in large volumes and numbers. The various stages and steps of moulding involve creating it with help of aluminium, steel or any other similar material. The machines we use help us in delivering outstanding precision and quality for our products and services. For the injection molding part, we follow careful steps for designing and completing the work keeping in mind the shape and various features of the part.

Plastic Injection Mold Designing Services

Get Price Quote

Situated in Shiva Nagar Colony Nagaram, Hyderabad, Telangana (India), Shidha Technologies is involved in providing superior class plastic injection mold designing services to the clients. We have hired a team of adroit plastic injection mold designing experts, who are proficient in melting the solid plastic resin pellets, injecting them into a mold and cooling them back to a solid-state. These experts make use of the most advanced tools & machines to render these services.

injection mould design services

Get Price Quote

we are offering injection mould design services.

Injection Mold Designing

Get Price Quote

Injection Mold Designing, Precision CNC WIRECUT EDM JOB WORK

Injection Mold Designing

Get Price Quote

Injection Mold Designing, plastic mold maker

Injection Mold Designing

Get Price Quote

Injection Mold Designing, Product Designing, Enclosure Designing

Injection Mold Designing

Get Price Quote

Injection Mold Designing, MBBR Media, Pvc Water Stopper

Injection Mold Designing

Get Price Quote

Injection Mold Designing, Injection Moulded Components, Ultra Sonic Welding

Injection Mold Designing

Get Price Quote

Injection Mold Designing, 2d drafting services, cnc programming

plastics injection moulds design services

Get Price Quote

plastics injection moulds design services, Design Services

injection molding design

Get Price Quote

injection molding design, acoustic analyzer, Finite Element Modeling

Injection Mold Designing

Get Price Quote

Injection Mold Designing

injection molding design

Get Price Quote

injection molding design

Advanced Injection Mold Design

Get Price Quote

Advanced Injection Mold Design

Injection Mold Designing

Get Price Quote

Injection Mold Designing, Medical safety Goggles, Textile Auxiliaries

plastic injection mould designing

Get Price Quote

plastic injection mould designing, plastic mould designing

Injection Mold/Mold Design and Engineering

Get Price Quote

Injection Mold / Mold Design and Engineering

Injection Molding Die Design

Get Price Quote

Injection Molding Die Design