Cast Iron breaking machine

250,000 - 500,000 Per piece

1 Piece (MOQ)

We are instrumental in manufacturing, exporting, and supplying industrial grade Casting Cracker. The Casting Cracker provided by us is designed for the effective breaking of Engine Blocks, Cast Iron Moulds, etc. The scrap is broken down into small non-uniform portions, which enables the increased recovery of the primary metals while re-melting. Thus, the Malwa Hydraulics’s Casting Crackers have proven to be effective for Industry related to cast iron. The clients can avail from us, these Casting Crackers at very affordable rates in the markets. Benefits Little dust formation Number of strokes for crushing procedure can be adjusted according to the material to be processed Low maintenance cost User- friendly

Iron Trailer Mounted Nala Cleaning Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Ironing Machine

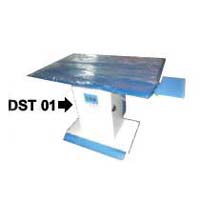

vacuum ironing tables

Get Price Quote

With the assistance of our highly skilled professionals, we are able to offer high-quality Vacuum Ironing Tables to the clients. We are based in Haryana, India. We offer it in various specifications, to suit a specific application. We are renowned for making timely deliveries of our consignments, even of the client places a bulk order.Features : Vibrationless & silent Fully Powder coated and treated for rust prevention Thermostatically controlled SS Heater Design for easy maintenance and servicing The modern & sturdy designed of vacuum table for wrinkle free & shine less Finishing Powder coated perforation Under this category, we offer the following models : Vacuum Ironing Table (DST 01) Vacuum Ironing Table (DST 02) Vacuum Ironing Table (DST 03) Vacuum Ironing Table (DST 04)

Scrap Car Bicycle Shredder Waste Steel Iron Aluminum Metal Crusher Machine

300,000 - 500,000 Per piece

1 Piece (MOQ)

SHREDALL Scrap Car Bicycle Shredder is Ultimate Solution for Waste Steel, Iron, Aluminum, and Metal Recycling. Our crusher machine efficiently shreds scrap cars, bicycles, and metal waste into reusable materials. Perfect for recycling centers and metal processing plants. Turn your waste into profit with our powerful shredder. "Transform scrap cars, bicycles, and metal waste into valuable resources with our Scrap Car Bicycle Shredder. Our efficient crusher machine swiftly shreds steel, iron, aluminum, and other metals, making recycling easy and profitable. Perfect for metal recycling facilities, our shredder ensures maximum efficiency in waste management. The Working of Metal Crusher Machine The metal crusher machine operates by crushing scrap metal into smaller pieces, facilitating easy recycling and reuse. It utilizes a powerful mechanism to break down steel, iron, aluminum, and other metals efficiently. This process reduces waste volume and prepares materials for recycling. Ideal for metal recycling plants, our crusher machine maximizes efficiency in metal waste management, promoting environmental sustainability and resource conservation. Key Features - Powerful crushing capability for steel, iron, aluminum, and other metals. - Versatile, suitable for shredding scrap cars, bicycles, and metal waste. - Compact design saves space in recycling facilities. - Durable construction for long-term use. - Easy maintenance and cleaning. - Safety features prevent accidents. - Eco-friendly, promotes recycling. - High efficiency for fast metal shredding. - Customizable to meet specific needs. - Reliable performance for continuous operation. Shredding Material Capable of shredding various materials including scrap cars, bicycles, steel, iron, aluminum, and other metal waste with ease. Versatile and powerful, our shredder handles diverse materials for efficient recycling. Shredding Machine Type It's a double shaft shredder, designed for maximum efficiency in shredding various materials. With dual shafts, it ensures thorough and effective shredding in a single pass. Usage/Application Ideal for recycling centers, metal processing plants, and waste management facilities. Capacity With a shredder from 1000 kgs/hr to 10,000 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation High performance and easy installation make this shredder perfect for any recycling operation. With its powerful capabilities and simple setup, it's a reliable choice for efficient waste management. Product Description Introducing our high-performance double shaft shredder, designed for efficient waste management. With easy installation and robust construction, this shredder is perfect for recycling centers and metal processing plants. Versatile and powerful, it efficiently shreds various materials including scrap cars, bicycles, steel, iron, and aluminum, promoting sustainability and resource conservation.

Cast Iron Hydraulic Surface Grinding Machine

850,000 Per Piece

1 Piece (MOQ)

Flatwork Ironer

Get Price Quote

Microprocessor control, finger guard protection, user-friendly system, frequency inverter, standardized automatic cooling down mechanism and exhaust functions are some of the striking features of our Flatwork Ironer. With extremely low maintenance, our highly energy efficient product helps gain maximum output results in terms of producing superior linen finishes. Our product is well equipped with a mirror finished cylinder, safe hand protection board, etc. Details : Our Flat Work Ironers produces high quality linen finishes easily and efficiently. The cylinder is mirror polished and supported by heavy-duty lubricated bearings. A highly sensitive hand protection board ensures ultimate safety in each phase of the ironing process. Our frequency conversion speed adjustment system allows for a continual even flow of speed which brings more energy saving. Speciality : Microprocessor control Finger Guard Protection User friendly control Frequency Inverter Standard automatic cool down Exhaust system Advantages : High productivity Minimum maintenance High quality finishing. Less energy consumption Cost effective. Model : Single roller, Double Roller, Three roller, Four Roller Size : 800 mm roller dia, 2500mm, 2800mm, 3000mm width.

Hydraulic Iron Worker Press Machine

165,000 - 210,000 Per Piece

1 Piece (MOQ)

Flat Work Ironer

Get Price Quote

flat work ironer / calander ironing with roller heating—single roller no need of compressor electric or steam heated

Iron Patti Straightener Machine

140,000 Per Piece

1 Piece(s) (MOQ)

Iron Worker Machine

Get Price Quote

note : dimensions, design, weight, & specifications can be change as market demands or further improvement of machine without notice. .

Vacuum Ironing Table

Get Price Quote

Our team makes it possible to carry out online transactions, keeping the details confidential. Our payment procedures and the transactions we make are completely transparent and thus, clients can trust on us. Designed and developed using the premium raw material and modern work methods; we guarantee high quality standards and longevity of our products. Also, we make sure that the raw material is sourced from the trusted places. Featured with adjustable height knob, our table dimensions 18 x 48 inch.

iron bar cutting machine

95,000 Per

We are the main supplier of this product.

1 HP Steam Ironing Machine

30,500 Per piece

HIW-65 Hydraulic Ironworker Machine

Get Price Quote

Salient Features “Programmable logic controls” (PLC) is provided in our Machine of international standard make Delta, offering maximum production flexibility and full compatibility with international standards. Both cylinder are work independent (two worker can work as same time) Stroke adjust with the help of proximity sensor and light indication glass for easy stroke adjustment,MONOBLOCK Structure and Precise machining of the structural membrane is done to get the required accuracies like parallelism between platen and bed and right angularity. Between bed and the moving platen. ‘Auto Lubrication System: All moving parts are lubricated from a centralized lubrication arrangement with auto timer, once you fill lubricant no worry for 2-3 months about lubrication. Auto hold down mechanism which will give fast production rate and it hold material with heavy force and cut material so increase Die life with better cutting quality, Quick Die – Punch Mechanism:- you can change punch fast and easy, All die are inter-changeable so one die can use 2 to 4 times, also material and process of die so that it will give longer life without blending edge, Universal angle cutting mechanism will give possibility to cut wide range of angle size in one die, no die change required for bigger or smaller size of angle. The low noise hydraulic power pack unit is designed as per international practices and assembled with internationally reputed make components. The presses are designed as per ISI guidelines, hence standard seals, bushes are used. Machine have Guard at all station, electric switch and rubber pad which provide safety for operator and protect machine again dust and free-falling metal while cutting, All station of Shearing have common Stroke Counter, it will Count Number of Cut. Table Design with ‘T’ Slot, Regular die of Power Press can be Use on Ironworker Machine. Machine comes with all Standard accessories spanner set, warranty Card, instructional and maintenance manual. Machine Comes with Standard Functional Accessories: Die Set (total 14 Nos.): A 10 Pair of Punch and Die (select Any 10 Round Punch + Die Set from Dia. 8 Mm to 20mm) A Set of Angle Steel Cutting Blade. A Set of Square and Round Bar (or I Section or C Section) Cutting Blade (any One of Three) A Set of Flat-bar Shearing Blade. A Set of Notching Blade (v- Notch or Square Notch Any One) Die Set is Customizable as per Your Requirement, Please Freely Discuss with Our Company. Standard Functional Accessories: Automatic Multi Point 24v Dc Motor Operated Lubracting System 3 in 1 Die Holder (50, 73 Die Holder & Angle Punching) Hydraulic Hold-down Mechanism (auto Hold Angle & Flat) Back Gauge Mode (inching, Auto) Both Side E/stop Two Saparat Foot Switch

Copper & Iron Removal Machine

Get Price Quote

1 piece (MOQ)

Iron Worker Machine

135,000 - 675,000 Per Piece

1 Piece (MOQ)

Cast Iron Tamping Rammer Machine

28,000 Per Unit

1 Unit (MOQ)

Iron Cake Cream Mixer Machine

Get Price Quote

1 Piece (MOQ)

Cast Iron Platen Punching Machine

4,500,000 Per Piece

Flatwork Ironer

835,000 Per Piece

2 Piece (MOQ)