Jacketed Reactor

450,000 - 625,000 Per Piece

1 Piece (MOQ)

Jacketed Mixing Reactor

Get Price Quote

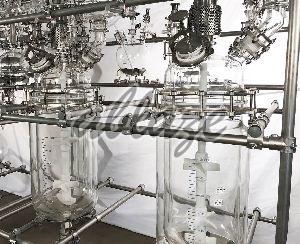

In the pharmaceutical and chemical industries, a Jacketed Reactor is used to control the temperature of its content via a heating or cooling jacket made around the vessel by circulating heating or cooling fluid through the jacket. Agitation is usually used in Jacketed Glass Vessels to improve the level of homogeneity in the properties of fluids such as concentration and temperature. The essential part of all the chemical processing units is a reactor. Hence it is widely accepted as the ‘heart’ of the processing system because it is considered as the most crucial component in the chemical industry. A glass reactor made from Borosilicate is known to offer a unique advantage of the visibility of reactions happening inside the reactor, which no reactor made from other materials can give. However, the user’s visibility advantage is compromised when the traditional methods are used to heat the contents inside the glass reactor. This provoked the industrialists to develop the Jacketed Glass Reactor Vessels. The design of a Jacketed Glass Reactor is made up of a vessel that is bounded by a layer like a jacket made up of glass through which the cooling and heating fluids are passed. The jacket is considered to be an isolated chamber around the vessel inside and is placed in a way that the content present inside of the vessel does not pose a direct contact with the jacket. Concerning various requirements, a nozzle is also provided in the jacket for venting purposes. The process of heat transfer happens across the walls of glass between the jacket and the inner vessel; moreover, the vessel is manufactured in such a way that the total area of the jacket always covers the ostensible volume of the whole reactor. The nozzles come with the universal M16/M30 connections; hence, you can connect the reactor to any internationally acclaimed Temperature Control Unit (TCU). Single Jacketed Reactors and double jacketed reactors are both used to perform particular reactions. Usually, in the single jacketed reactors, the area of the jacket is used to circulate fluid that will control the temperature of the reaction within the vessel. However, sometimes the need for an additional jacket arises for insulation purposes; that is when the double jacketed reactor comes to use. These reactors consist of the usual accessories such as valves, stirrer, and support structure required to build a reaction unit. If you want to install a vapor nozzle, you have the liberty to assemble it as per the requirement. These reaction units are highly customized, and its design varies from customer to customer as per their requirements. Standard units of 50 Litres capacity can be used for general reactions. Options of Jacketed Glass Reactors Jacketed Reactors can be customized concerning various options concerning their size and utility. Below are the options available in Jacketed Glass Reactor Unit: Stirrer Drive: Has a non-flameproof or flameproof Motor, Ex-proof, which runs at 250 RPM with the in-built speed regulator. Stirrer for Construction material: It is made up of glass or is lined by PTFE, Hastelloy, SS316L. Stirrer shape: It comes in a variety of stirrers such as the Glass Impeller Stirrer with an in-built PTFE Blades, a Vortex Stirrer, a propeller stirrer, and an anchor stirrer. Stirring Assembly: Stirring Assembly comes with a mechanical or a bellow seal. Supporting Structure: Can be made up of Epoxy coated Carbon Steel, Carbon Steel, Stainless Steel with 304 and 316 variants. All these structures can be made available to you in the Trolley mounted form as per your requirements. Closing Valve: It is designed to drain or flush the bottom outlet. Advantages : Pt100 sensor works accurately in measuring high temperatures and small errors, which will improve the work efficiency and make it better; The heating or cooling material poured in the interlayer of the reactor can be released after the completion of the reaction; hence, no liquid gets compiled; The overall column made with Stainless Steel frame structure is strong enough to last long. It comes with a five reactor lids, a full set of reflux, external addition of liquid, and a tool to measure the temperature; It is built with substantial torque and is absolutely noiseless. AC gear reduction motor made with Japanese technology is endorsed; Stirring paddle made up of double-tetrafluoroethylene is specially designed for such glass reactors as they are highly suitable for mixing of any liquid material regardless of low or high viscosity. Salient Features : It is built with Borosilicate glass 3.3 and has excellent physical as well as chemical properties. It has an inbuilt ATEX Motor, a digital display that shows the mixing speed, a frequency conversion tool, and it is brushless, the mixing system works at a constant rate, it is sparkless, absolutely safe and stable. It is manufactured with rugged steel and reinforced PTFE stirrer along with an anchor agitator that favors a variety of material viscosity. It has PTFE discharge valves that can discharge or dispose of the materials quickly and thoroughly. It is proven to work under pressure as well as in the vacuum conditions, under the vacuum. The Ex-proof motors can be attached as an option for 10L, 20L, 30L, 50L, 100L, 150L. The whole structure is unique, practical, and beautiful. Working : The cooling or heating liquid is injected in the space between the glass walls of the jack and the inner vessel. You can now connect a double lined glass reactor with an external cooling or heating equipment. Start the agitator so that the heat generated by the agitator can stir the content inside the vessel at the constant speed. It is proven to react and stir under the natural pressure as well as the negative pressure while in a sealed reactor. The outlet valve can be used to empty the material from the bottom of the reactor. It is quite an easy task to operate the reactor. The reactor can ideally be used as an instrument that is meant for conducting the experiments of modern chemistry, Pharmacy, Biochemical tests, and the advanced synthetic. Jacketed Glass Vessels can be used in which industries? Jacketed Glass Vessels are the most common equipment to be used in industries such as petrochemical, pesticide, rubber, pharmaceutical, dye, and also some industries use the Jacketed reactors to complete the process of sulfonation, hydrogenation, nitration, polymerization, alkylation, condensation, and many other means as well.

Best Deals from Jacketed Reactors

jacketed reactors

165,000 Per Piece

1 Piece (MOQ)

Jacketed Reactor

200,000 Per Piece

1 Piece(s) (MOQ)

We are here to guide our clients with the secure payment procedures. With us, the customers get convenience to pay through both online and offline payment methods We keep close eye on the quality of the products so as to deliver the best in class range. Features: High-performance Robust construction Easy operations & maintenance

stainless steel jacketed reactor

65,000 Per Piece

1 Piece (MOQ)

Jacketed Reactor

Get Price Quote

Jacketed Reactor

120,000 - 550,000 Per Piece

1 unit (MOQ)

This is a general purpose reactor, to be operated at atmospheric pressure, or vacuum. These vessels are provided with jacketed cylindrical vessel, cover, flush bottom valve, thermometer pocket, liquid inlet tube, Gas sparging tube, vent valve, anchor stirrer and mechanical seal. Other type of stirrer can be provided in place of anchor stirrer on demand. A battery of 4 PTFE baffles, removable type can be provided. Condenser assembly as per requirement can be attached ( can be ordered separately ) on the vapour nozzle.

jacketed reactors

Get Price Quote

1 Piece (MOQ)

Jacketed Reactor

Get Price Quote

In Conventional Jackets second shell is installed over a portion of the vessel, creating an annular space within which cooling or heating medium flows. A simple conventional jacket, with no internal components, is generally very inefficient for heat transfer because the flow media has an extremely low velocity resulting in a low heat transfer coefficient. Condensing media, such as steam or Dowtherm A, is an exception because in this case the heat transfer coefficient doesn't depend on velocity or turbulence, but instead is related to the surface area upon which the media condenses and the efficiency of removing condensate. Internals include baffles that direct flow in a spiral pattern around the jacket, and agitating nozzles that cause high turbulence at the point where the fluid is introduced into the jacket.

Jacketed Glass Reactor

Get Price Quote

1 Piece (MOQ)

Our state-of-the-art Jacketed Reactor Pilot Plant is meticulously crafted to enhance your processes and streamline production efficiency. Representing a culmination of equipment evolution and customer needs, our jacketed glass reactors offer unparalleled versatility for various tasks such as stirring, dissolving, mixing, and extraction. Our reactors redefine possibilities with features like heat exchangers for optimal dissolving and crystallization, mobility for seamless transport, and optional condensers for vacuum distillation. Available in cylindrical shapes and sizes ranging from 5 to 30 liters, K-Jhil’s Jacketed Reactor Systems set the standard for innovation in the industry.Salient Features : Advanced reactor Systems : Immerse yourself in cutting-edge reactor systems designed for precision, versatility, and efficiency. Modular Design for Flexibility : Our Pilot plant embraces a modular design, allowing flexibility to adapt to various mixing and reaction processes. Real-time monitoring and control : Experience the power of real-time monitoring and control systems, ensuring accuracy and enabling data-driven decision-making. Highly Customizable Parameters : Tailor the mixing and reaction parameters to your specific requirements, empowering you with unparalleled control over your processes. Applications : Pharmaceuticals Process Development : Conduct pilot-scale studies for pharmaceutical manufacturing, optimizing reaction conditions and ensuring scalability. Polymerization Studies : Explore polymerization processes with precision and control, tailoring polymer properties for specific applications. Chemical Processing : Conduct pilot-scale studies for pharmaceutical manufacturing, optimizing reaction conditions and ensuring scalability.

Horizontal Double Wall Jacketed Chemical Reactor

Get Price Quote

1 Piece (MOQ)

jacketed reactors

Get Price Quote

We are strongly backed by a well maintained and managed storage house wherein we store our products for meeting urgent and massive requirements of the buyers. We are one of the respected names in the market of Maharashtra(India) and are offering amazing deals on our products.

Jacketed Reactor

900,000 Per Set

01 Piece(s) (MOQ)

We are one of the leading manufacturers of jacketed reactors in india. Our jacketed reactors are highly durable and long lasting. Jacket reactors manufactured by us include m. S jacketed reactor, s. S jacket & reactor, m. S limpet coil reactor, s. S vessel with m. S jacket etc. We serve various pharmaceutical companies with our stringent quality jacketed reactors. Moreover, our jacketed reactors are available at very moderate rates with us.

Jacketed Reactor

450,000 Per Rs

Jacketed Reactor

Get Price Quote

In chemical engineering, a jacketed vessel is a container that is designed for controlling the temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated. A jacket is a cavity external to the vessel that permits the uniform exchange of heat between the fluid circulating in it and the walls of the vessel. There are several types of jackets, depending on the design These jacketed reactors are very smooth, corrosion resistant and very easy to maintain. Clients can avail our jacketed reactors at economical prices. Features : Quality tested Very efficient to use Supreme strength Economical

jacketed reactors

Get Price Quote

The systems are available with different options, depending upon their size & their utility. Our Technical Department will glad to assist you in finding a suitable solution for your process requirement. 1. Stirrer Drive: Non-Flameproof or Flameproof Motor, 192 RPM with speed regulator. 2. Stirrer material of construction: Glass or PTFE Lined. 3. Stirrer shape: Glass Impeller Stirrer with PTFE Blades, Vortex Stirrer, propeller stirrer & anchor stirrer. 4. Stirring Assembly: Stirring Assembly with bellow seal or with mechanical seal. 5. Supporting Structure : Carbon Steel, Epoxy coated Carbon Steel, Stainless Steel 304 & Stainless Steel 316. 6. Closing Valve: Drain Valve or Flush Bottom Outlet Valve.

Jacketed Reactor

65,000 Per Piece

01 Piece (MOQ)

Jacketed Reactor

Get Price Quote

1 Piece (MOQ)

Jacketed Reactor

Get Price Quote

We are offering Jacketed Reactor in the market. Jacketed Reactors, offered by us, have a sturdy construction, and high efficiency. Jacketed Reactors are used for carrying out a number of chemical reactions. These Jacketed Reactors have a jacket on them, and are designed in such a way to ensure that chemical reactions inside it proceed efficiently.

Jacketed Glass Reactor

Get Price Quote