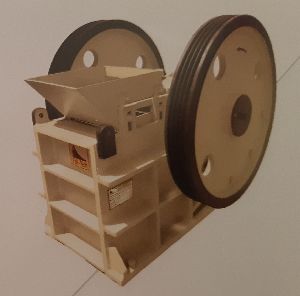

Single Toggle Jaw Crusher

Get Price Quote

1 Piece (MOQ)

Jaw Crusher

Get Price Quote

We are offering Jaw Crusher etc.We are offering Jaw Crusher in the international markets. Jaw Crushers offered by us are designed and made by skilled engineers with the help of latest manufacturing techniques. Made available in mild steel body, our Jaw Crusher is appreciated by the clients for its sturdy construction. Jaw Crusher crushes material between fixed jaws and swing jaws. Features : * Wear and tear resistant * Smooth running * Reserved power * Durable Construction : * Main driving shaft for elliptical to and fro motion in jaw stock * Adjustable discharge opening to control end product size * Two heavy cast iron flywheels for steady running * Drive arrangement: flywheels or suitable pulley * Cast iron/mild steel jaw stock * Manganese alloy iron or steel Swing jaw * Replaceable manganese alloy or steel fixed jaw * Two fold check plates * Steel Tie Rod * Heavy duty ball Bearing and Roller Bearing * Cast iron fly wheel * Cast iron Toggle plate » Specifications Size of Machine Production Capacity in M Tons of Granite/Hour at discharge Setting RPM HP 0.5 0.75 1 1.5 2 2.5 3 6x3 0.25 0.5 0.7 1 -- -- -- 350 3 - 5 6x4 0.25 0.6 0.8 1.1 -- -- -- 350 3.5 9x5 0.75 1 1.25 2 -- -- -- 275 5-7.5 12x6 1.1 1.3 1.7 2.5 2.75 -- -- 225 7.5-10 14x4 1 1.25 1.5 2 -- -- -- 225 7.5-10 14x6 1.1 1.4 1.8 2.75 3 -- -- 225 7.5-10 16x5 2 2.75 4.5 5 -- -- -- 175 15-20 16x6 2.25 3 5 5.5 6 -- -- 175 15-20 16x9 -- 3 5.5 6.5 7 7.5 -- 175 20-25 20x12 -- -- 7 8 10 12 14 150 30-35 24x12 -- -- 8 9 11 13 16 150 35-40 24x16 -- -- -- 10 12 15 18 125 35-40

Best Deals from Jaw Crusher

Single Toggle Jaw Crusher

1,050,000 Per Set

1 Set (MOQ)

Astm Cone Crusher Machine

Get Price Quote

1 piece (MOQ)

Jaw Crusher

Get Price Quote

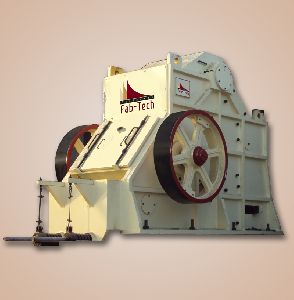

Details We manufactures two types of Jaw Crusher, Single toggle and Double toggle. Single toggle Jaw Crusher have simple and robust construction with grease lubricated bearings design, which is easy to maintain and economical. This machine gives higher percentage of fines. Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles, the machine works with the help of two toggles, so that it’s generates less fines and particles come with sharp edges.

Single Toggle Jaw Crusher

0 - 0 Per Piece

1 Piece (MOQ)

Jaw Crusher

500,000 Per Piece

Stone Jaw Crusher

1,050,000 Per Piece

1 Piece (MOQ)

Jaw Crusher

75,000 Per piece

Double Toggle Secondary Jaw Crusher

Get Price Quote

1 Piece (MOQ)

Jaw Crusher

Get Price Quote

Features: Used for crushing the stones and dolomites Coated with an abrasion resistant material Highly durable

Aggregate Jaw Crusher

Get Price Quote

Laboratory Jaw Crusher

475,000 Per Piece

1 Piece (MOQ)

Single Toggle Jaw Crusher

Get Price Quote

1 Unit (MOQ)

120TPH Stone Jaw Crusher Plant

12,700,000 Per piece

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top then at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom opening. The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that cause closing of the gap.Single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. The crushers components are of high strength design to accept high power draw. Manganese steel is used for both fixed and movable jaw faces. Heavy flywheels allow crushing peaks on tough materials. Double Toggle jaw crushers may feature hydraulic toggle adjusting mechanisms.

Jaw Crusher Machine

900,000 Per Unit

1 Unit (MOQ)

Jaw Crusher

Get Price Quote

1 Piece (MOQ)

With stern quality analysis of the raw materials and other inputs used, we make certain that the final product is absolutely free from defects. For this, we make use of the updated technology and machines. Emerged as an eminent Supplier, we are well-known for dispatching the comprehensive range of Jaw Crusher.

Jaw Crushers

Get Price Quote

We offer high quality Jaw Crusher available with adjustable jaw setting. These Jaw Crushers are highly energy-efficient. These Jaw Crushers are known for low-maintenance cost. We have built a positive image in the market as a Manufacturer and Supplier of technologically advanced Jaw Crushers used for construction processes. Range Jaw Crusher (9X16 Inches) Jaw Crusher (10X20 Inches)

Double Toggle Jaw Crusher

Get Price Quote