Board Knurling Machine

Get Price Quote

1 Piece (MOQ)

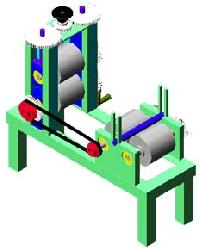

Suitable for "Memory" Board Knurling Machine is specially designed to emboss different pattern on Paper & Board "Memory" Board Knurling Machine is specially designed to emboss different pattern on Paper & Board The machine is suitable for many applications like : Packing Boxes, Playing Cards, Box Covers, Greeting Cards, Gift Envelopes, Calendar etc, Salient Features: The Solid Cast Iron body with powde coating ensures trouble - free & long working life. The machine is equipped with a high precision CNC laser engraved design roller, self manufactured paper Bowl roller to emboss the substrate, so that the desired pattern appears. Manual Hydraulic Pressure with Japanese Hydraulic Cylinders, individual pressure control for either side to adjust design pressure as per requirement Twin De-curling Rollers, Air Knife & bottom Wiper Unit to avoid paper sticking on the roller surface after embossing. Sheet counter with photo electric sensor, adjustable paper feeding & delivery table. Optional Automatic Feeder Automatic Hydraulic Pressure Laser Engraved Design Roller

Hydraulic Pipe Knurling Machine

410,000 - 475,000 Per piece

1 Piece (MOQ)

Best Deals from Knurling Machine

automatic knurling machine

Get Price Quote

We are engaged in manufacturing and exporting of Automatic Knurling Machine. These Automatic Knurling Machines are manufactured using latest technology and optimum quality components. With the help of this machine shells are knurled & perforated by means of precisely wire cut rollers by means of rolling. The clients can avail Automatic Knurling Machine at competitive price.

Multi Spindle Knurling / Beading & Perforating Machine

Get Price Quote

- Designed for High Speed Production - Caps are fed to the machine by feeder device and delivered to combination tool set. - Wearing parts such as Knurling and Perforating cutters can be quickly replaced, without the need to disassemble the entire unit - The chuck is controlled by a gear and has a system for simple alignment of knurling

Board Knurling Machine

Get Price Quote

Features : “Memory" Board Knurling Machine is specially designed to emboss different pattern on Board. The machine is suitable for many applications like : Packing Boxes, Playing Cards, Book Covers, Greeting Cards, Gift Envelops, Calender etc. The sturdy fabrication with powder coated mild steel structure ensures trouble - free & long working life. The machine is equipped with a high precision engraving roller to emboss the substrate, so that the desired pattern appears.

single spindle knurling machine

Get Price Quote

Knurling Cutter Machine

Get Price Quote

Offered by us is Knurling Cutter Machine that cut the material in required dimensions. The Knurling Cutter Machine offered by us is precisely developed by the knowledgeable experts in the company. Also, these Knurling Cutter Machines are customized in order to match with the specifications provided by the customers. Used For : Corrugating graphite sheet Renowned For : Variable knurling size Simple designAuto winding mechanismEasy detachable knurling rollsOptional length counter Technical Specifications MACHINE TYPEKCM-25KCM-50KCM-75KCM-100Length L (mm)600600600600Width D (mm)225250275300Height H (mm)550550550550Max. Processing Th. (mm)0.50.50.50.5Operating SystemManualManualManualManualKnurling Roller MaterialS.S. 304S.S. 304S.S. 304S.S. 304Pulling Roller MaterialS.S. 304S.S. 304S.S. 304S.S. 304OptionsOperating System (With Motor)2222Knurling Roller MaterialM.S.M.S.M.S.M.S.Pulling Roller MaterialM.S.M.S.M.S.M.S.

Board Knurling Machine

350,000 - 425,000 Per One

1 Piece (MOQ)

we are offering Board Knurling Machine

multi spindle knurling machine

Get Price Quote

Knurling Machine

Get Price Quote

The rigid and robust construction of the Groz range of knurling tool holders makes them ideal for countless knurling applications. The revolving head is fitted with standard left and right pattern knurls in fine, medium and coarse pitch. Any pair can be brought to bear on the workpiece, thus 3 different knurling patterns are obtainable without changing the tool.

multi spindle knurling machine

Get Price Quote

Knurling Scoring Machine

Get Price Quote

This machine is specially designed for pilper proof caps of any size from 22 mm to 53 mm and also machine is very highly accurate for mass production. This machine is totally running on ball and needle Roller bearing with hardened and ground shafts for its better service years and years. Specifications 1. Capacity 22 mm to 53 mm 2. Output 3000 to 3200 per hour 3. Net Weight 550 Kgs. 3. Electricals 1 HP 1440 RPM 3 ph 50 hz Back

Knurling Machine

Get Price Quote

Knurls are Hob Cut from High Speed Steel and Heat Treated. Six knurls tools is provided with one pair each of fine medium and coarse knurls. Two knurls Tool is generally provided with medium knurls but other knurls can also be provided if required. Machined ground steel in Shiny Black Finish. Replacement knurls are offered as a complete spare set for knurling Tools.

Board Knurling Machine

Get Price Quote

We are offering board knurling machine. "memory" board knurling machine is specially designed to emboss different pattern on paper & board. The machine is suitable for many applications like: packaging boxes. Playing cards, book covers, wedding & greeting cards,gift envelopes, calender etc. Heavy duty cast iron structure with powder coating paint ensures trouble free & long working life. Features includes: hydraulic pressure setting for even impression, digital paper counter & variable speed air knife for thin paper. Twin de-curling rubber roller prevents paper creasing. Individual hydraulic pressure control for left & right sides for even and better design transfer on paper & board.

Knurling SPM

Get Price Quote

Many components like handle bars, drive shafts etc in bicycle, automobile industries, pump manufacturing industries etc need knurling operation on OD, for providing better grips of mating part. Knurling is normally done in a lathe or in a HMC. But these machines are not designed for taking the plunge load of knurling. We have designed & developed a Special Purpose machine which can mass produce knurled components are very high speeds, requiring less cycle time & high output. Construction: On a heavily ribbed, fabricated & stress-relieved machine base, a Head Stock is mounted. Located in the head stock is the Spindle, rigidly supported by 2 pairs of heavy duty, matched pair angular contact bearings. Spindle, powered by a VFD controlled 3 HP motor, provides stepless spindle speeds from 300 RPM to 600 RPM in a stepless range. Mounted on the head stock spindle is the optionally offered 3 jaw self centering conventional or hydraulic chuck. On the other end of the base, Tail Stock is mounted. Tail stock has 2 different movements:- Hydraulically operated to & fro movement of the tail stock spindle for holding the job between centers and Motorized to & fro movement of the tail stock assembly to take care of varying lengths of the jobs. Located between the head stock and the tail stock is the Carriage, mounted on which is the specially designed HSS Knurling Wheel to produce knurled surface on a cylindrical job. Opposite to the knurling wheel, Teflon idle roller assembly counter-supports the job when receiving the plunge load of knurling and prevents the job from bending. Carriage moves between the head stock and tail stock with the help of a Servo Drive, in combination with HMI (HUMAN MACHINE INTERFACE) which offers 3 distinct advantages: Selection & ensuring of positioning accuracy with unfailing repeatability is ensured by the servo drive. Servo drive also takes the knurling wheel to the exactly required knurling length, wherever the knurling length required is more than the width of the knurling wheel. Servo drive makes it possible to produce multiple knurled surfaces of different knurling widths, on different jobs of different dimensions at single or multiple locations. The touch screen enabled HMI facilitates for quick program selection for different jobs, on-machine program edit, insertion of new programs, quick editing of cutting parameters like feed, speed etc. Centralize Lubrication System provides lubrication to the sliding and rotating parts of the machine at regular intervals. Cutting oil is continuously being pumped to the machining zone from a separate reservoir, fitted with a pump

single spindle knurling machine

Get Price Quote

Paper Knurling Machine

Get Price Quote

Paper Knurling Machine, Semi Automatic Paper Cutting Machine

SHAFT UNDERCUT AND KNURLING MACHINE

Get Price Quote

Knurling Machine

Get Price Quote

Knurling Machine